Environment-friendly building anticorrosive material and preparation method thereof

An anti-corrosion material and construction technology, applied in the direction of building insulation materials, buildings, building components, etc., can solve the problems of low water seepage strength, poor impermeability, poor anti-corrosion performance, etc., to achieve the suppression of continuous spreading, high strength, and improved waterproof effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

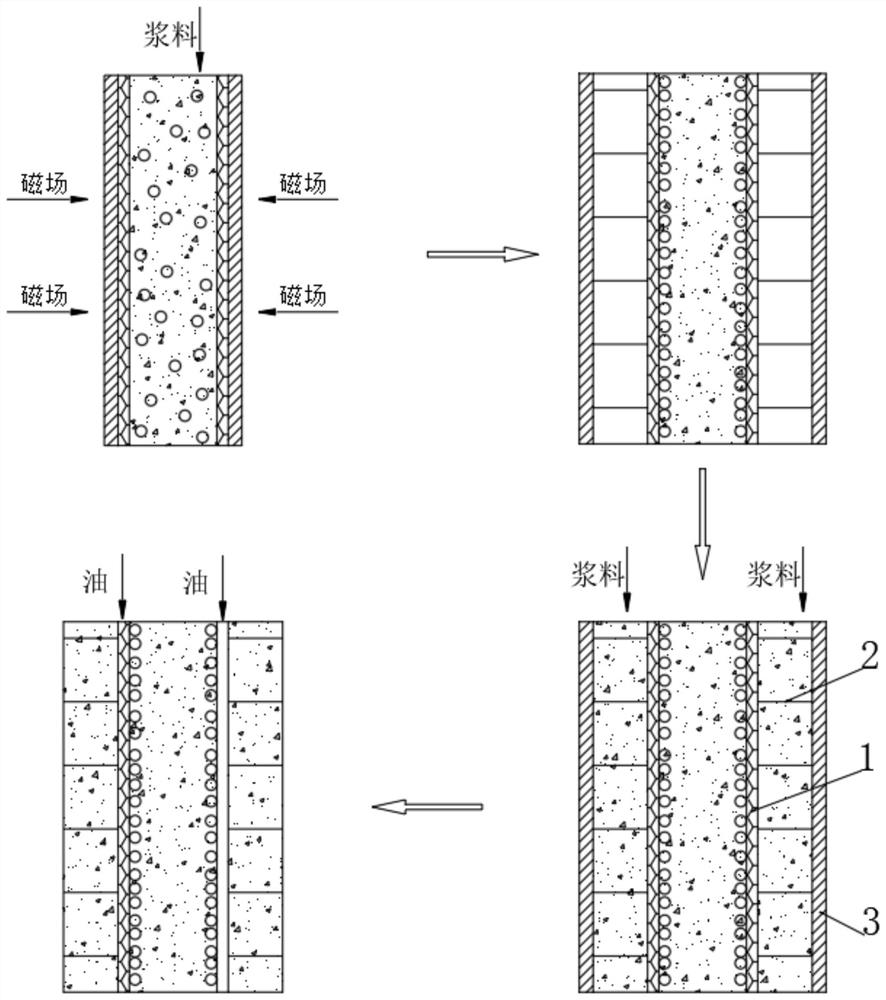

Method used

Image

Examples

Embodiment 1

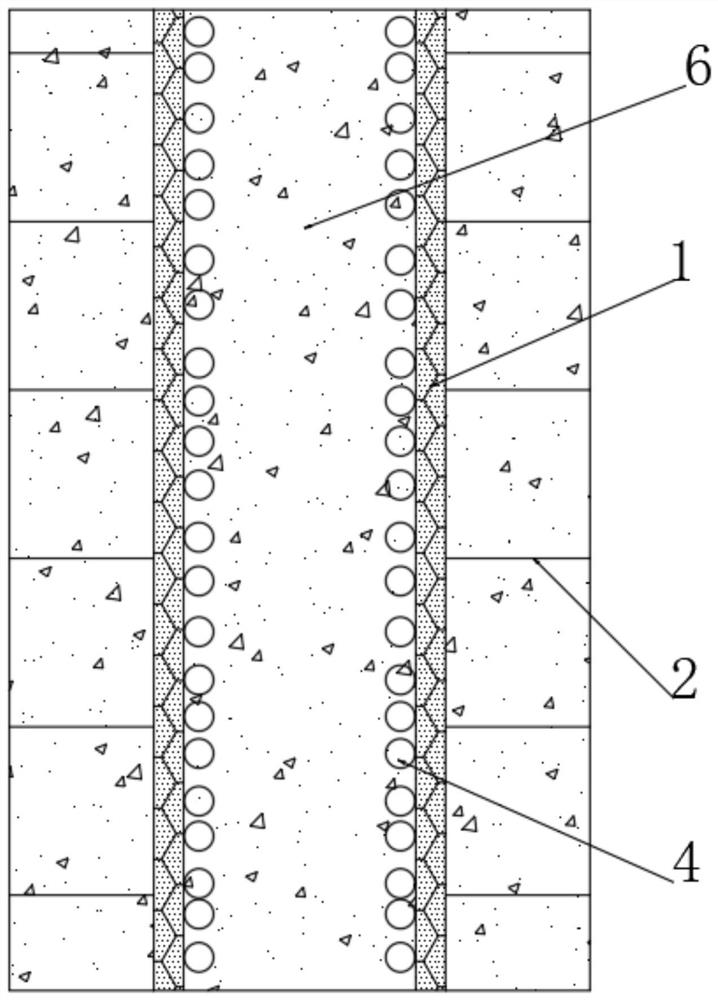

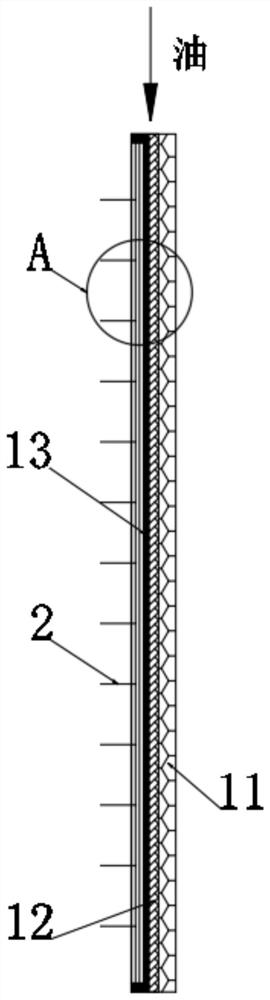

[0051] see figure 2 , an environmentally friendly building anti-corrosion material, comprising a concrete main board 6, two inner panels 1 are fixedly inlaid in the middle of the concrete main board 6, and a plurality of magnetic balls 4 are provided at the ends of the two inner panels 1 close to each other. The balls 4 are all in contact with the inner panels 1, and the outer ends of the two inner panels 1 are fixedly connected with a plurality of position-control pull ropes 2 that are evenly distributed. The surface is even, the inner panel 1 is impregnated with liquid oil, the position control stay cord 2 is stretched straight, and the position control stay cord 2 is made of non-elastic material, so that during the pouring process, the extension panel 3 is pulled outward At the same time, the distance formed between the two sides and the inner panel 1 is the same, so that the distribution of the internal oil interlayer is relatively uniform, and the performance of anti-see...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com