High-water-level loess stratum multi-track railway composite overhead system and construction method thereof

A construction method and high water level technology, applied in roads, excavations, tracks, etc., can solve problems such as inability to construct and ensure the quality of piles, and achieve the effect of solving construction bottlenecks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings.

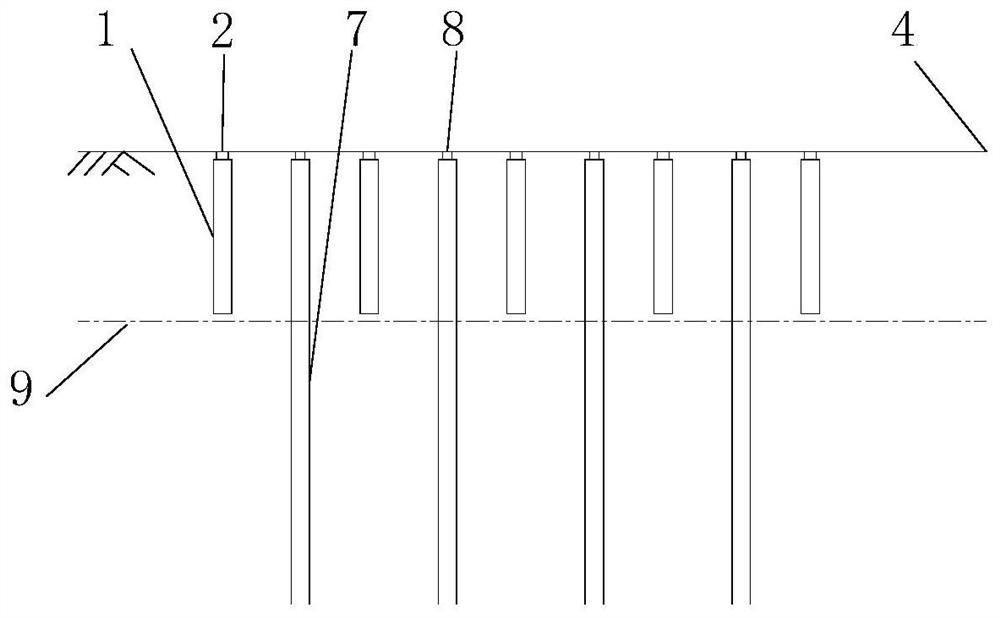

[0033] see figure 1 , figure 2 , a composite overhead system of a multi-strand railway in high-water loess stratum, comprising a number of temporary overhead piles 1 arranged along the length direction of the multi-strand railway 10, the tops of the temporary overhead piles 1 pass through the D-shaped beam 2 and the multi-strand rail The track 4 is contacted and connected, and the two sides of the track 4 of the multi-strand road are respectively provided with water-stop curtains 3, and the temporary overhead piles 1 connected by two adjacent rows of D-shaped beams 2 are provided with a working foundation pit 5, and a working foundation pit 5 There are dewatering wells 6 on both sides, and formal aerial piles 7 are arranged in the working foundation pit 5, and the tops of the official aerial piles 7 are connected to the track 4 of the multi-strand road thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com