Low-temperature rapidly-vulcanized polyurethane high-temperature adhesive as well as preparation method and application thereof

A high-temperature adhesive and rapid vulcanization technology, applied in polyurea/polyurethane adhesives, adhesive types, adhesives, etc., can solve problems such as environmental and human impact, pungent smell and smoke, non-energy saving and environmental protection, etc. Achieve the effect of increasing profit, reducing odor and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

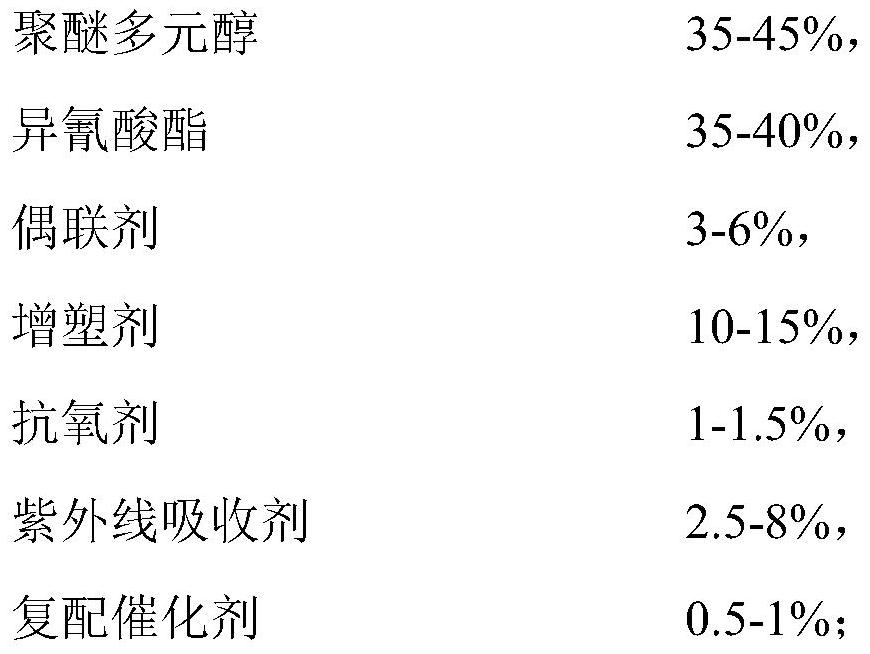

Method used

Image

Examples

Embodiment 1

[0034] Put 400g of diphenylmethane diisocyanate into the reaction kettle, start stirring, add 175g of VORAPEL WT5000 and 60g of VORANOL 1000LM under the condition of 45±5℃, raise the temperature to 70±5℃ in 40min, keep it warm for 2h, and then put in 77g of long-chain chlorinated paraffin With 38g triethyl phosphate, 30g Z-6020, 15g anti-oxidant 1010, 15g UV-329, keep the temperature at 70±5℃, after reacting for 1h, take a sample to test the NCO%, after the NCO is qualified, add 3g compound catalyst, stir for 30min , that is, polyurethane high-temperature adhesive, and the product is obtained by filling barrels.

Embodiment 2

[0036] Put 350g of diphenylmethane diisocyanate into the reaction kettle, start stirring, add 225g of VORAPEL WT5000 and 20g of VORANOL 1000LM under the condition of 45±5℃, raise the temperature to 75±5℃ in 60 minutes, keep it warm for 2 hours, and then put in 66g of long-chain chlorinated paraffin With 34g triethyl phosphate, 60g Z-6020, 10g anti-oxidant 1010, 10g UV-329, keep the temperature at 75±5℃, after reacting for 1h, take a sample to test NCO%, after the NCO is qualified, add 5g compound catalyst, stir for 30min , that is, polyurethane high-temperature adhesive, and the product is obtained by filling barrels.

Embodiment 3

[0038]Put 380g of diphenylmethane diisocyanate into the reaction kettle, start stirring, add 190g of VORAPEL WT5000 and 60g of VORANOL 1000LM under the condition of 45±5℃, raise the temperature to 75±5℃ in 50min, keep it warm for 1.8h, and then put in 66g of long-chain chloride Paraffin wax and 34g triethyl phosphate, 40g Z-6020, 10gUV-329, 10g anti-oxidant 1010, keep the temperature at 70±5°C, after reacting for 1.5h, take a sample to test the NCO%, after the NCO is qualified, add 4g compound catalyst, stir After 30 minutes, the polyurethane high-temperature adhesive was obtained, and the product was packed into barrels.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com