Storage device for special aluminum oxide

A storage device and alumina technology, which is applied in packaging, transportation and packaging, transporting passenger cars, etc., can solve problems such as deterioration of alumina powder, uneven heating of alumina powder, incomplete drying of alumina powder, etc., and achieve reduction Waste of resources, avoid incomplete drying, and improve drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

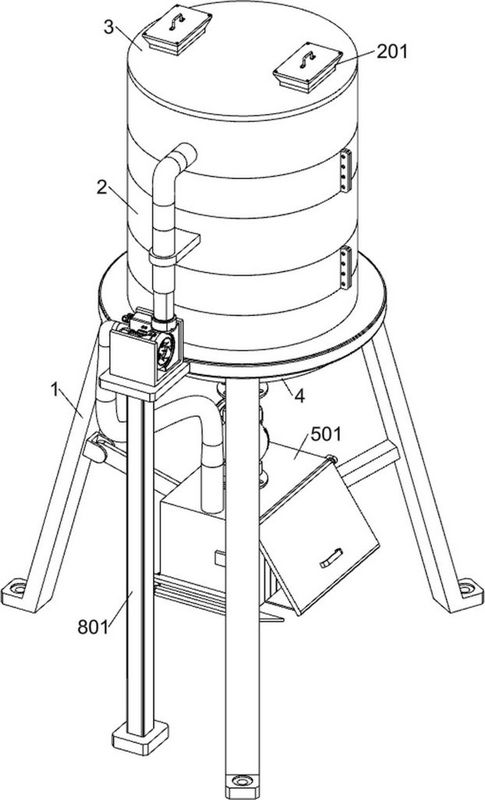

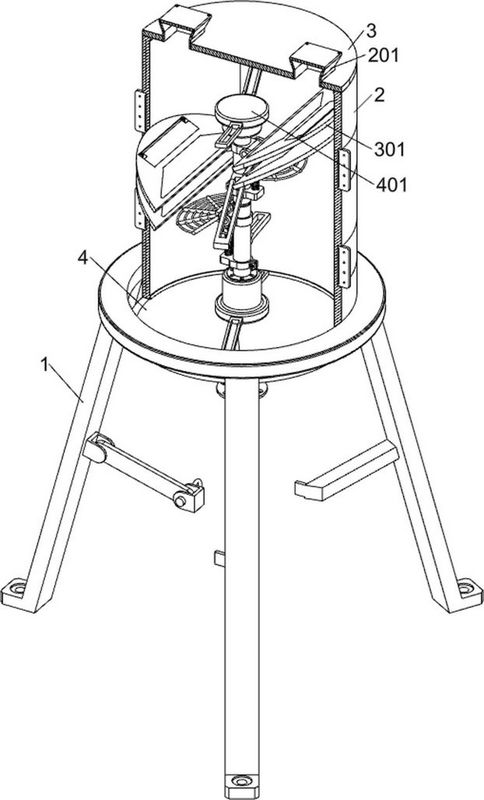

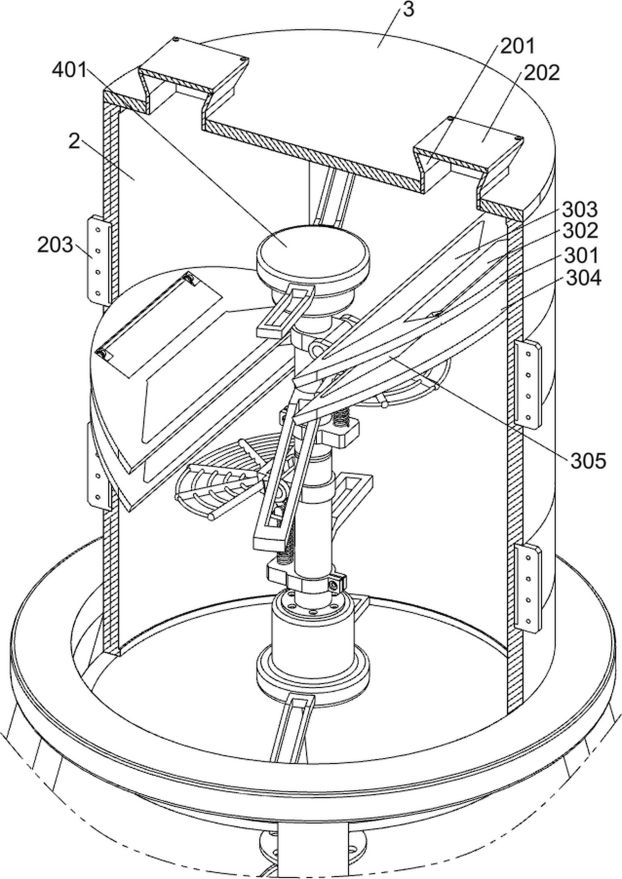

[0032] A storage device for specialty alumina, such as Figure 1-4 As shown, it includes a first frame 1, a first tank body 2, a first top cover 3, a first bottom cover 4, a first line column 401, an outer ring drying assembly, a split flow drying assembly and a middle drying assembly The upper part of the first frame 1 is fixedly connected with the first tank body 2; the upper part of the first tank body 2 is fixedly plugged with the first top cover 3; the lower part of the first tank body 2 is welded with the first bottom cover 4; The middle part of the body 2 is fixedly connected with the first line column 401 through the connecting frame; the outer ring drying assembly is installed on the outside of the first tank body 2; the outer ring drying assembly is connected with the first top cover 3; the inner side of the first tank body 2 is upper right A split flow drying assembly is installed at the top; another split flow drying assembly is installed at the inner left middle o...

Embodiment 2

[0039] On the basis of Example 1, such as figure 1 and Figure 5-7 As shown, a sealing assembly is also included. A sealing assembly is installed inside the first frame 1. The sealing assembly includes a first limit frame 501, a first support frame 502, a first motor 503, a first transmission rod 504, a first Cover plate 505, first spur gear 506, second transmission rod 507, second spur gear 508, first transmission wheel 509, second support frame 5010, third transmission rod 5011, second cover plate 5012, second transmission wheel 5013, the second motor 5014, the fourth transmission rod 5015, the third cover plate 5016, the first rubber curtain 5017, the first valve 5018 and the first pipe 5019; the inside of the first frame 1 is fixed with the first limit frame 501 ; The lower part of the front side of the first limiting frame 501 is fixedly connected with the first support frame 502; the first motor 503 is installed on the left part of the first support frame 502; the first...

Embodiment 3

[0042] On the basis of Example 2, such as figure 1 and Figure 8 As shown, a collection assembly is also included, the collection assembly is installed in front of the first frame 1, and the collection assembly includes a third support frame 801, a first pump machine 802, a second pipeline 803, a third connecting block 804 and a third pipeline 805; a third support frame 801 is installed in front of the first frame 1; a first pump 802 is installed on the top of the third support frame 801; a second pump 802 is connected between the input end of the first pump 802 and the first limit frame 501 The pipeline 803; the third pipeline 805 communicates between the output end of the first pump 802 and the first tank body 2; the third connection block 804 is fixedly connected to the middle of the first tank body 2; the third pipeline 805 penetrates and is fixed on the third connection on block 804.

[0043] When the alumina powder was impacted and dispersed in the first limiting frame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com