Highlight for cosmetics and preparation method thereof

A technology of cosmetics and pearlescent agents, which is applied in the field of high gloss for cosmetics and its preparation. It can solve the problems of destroying makeup, agglomeration, floating powder, etc., and achieve the effect of improving the use effect, improving gloss, and reducing floating powder or agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A three-dimensional high-gloss raw material includes the following components: A-phase pearlescent agent 23.85kg, B-phase pearlescent agent 11.92kg, C-phase pearlescent agent 7.16kg, D-phase pearlescent agent 7.15kg, E-phase pearlescent agent 5.961kg, F-phase pearlescent agent 4.18kg kg.

[0040] Highlight raw materials also include other additives, and other additives are: skin conditioner 2.44kg, cetyl ethylhexanoate 9.77kg, anti-caking agent 8.55kg, preservative 0.63kg, emulsifier 8.55kg, adsorbent 7.33 kg, humectant 1.47kg, solubilizer 0.98kg, PH regulator 0.06kg.

[0041] In this embodiment, the phase A pearlescent agent is: 18.12 kg of aluminum oxide, 0.24 kg of tin oxide, and 5.49 kg of titanium dioxide.

[0042] Phase B pearlescent agent is: 7.03kg of aluminum oxide, 0.24kg of tin oxide, and 4.65kg of titanium dioxide.

[0043] Phase C pearlescent agent is: 4.23kg of mica, 1.36kg of titanium dioxide, and 1.57kg of iron oxide.

[0044] Phase D pearlescent agen...

Embodiment 2-17

[0061] The difference between Examples 2-5 and Example 1 is that the raw material ratio of highlights is different, see Table 1 for details.

[0062] Table 1

[0063]

[0064]

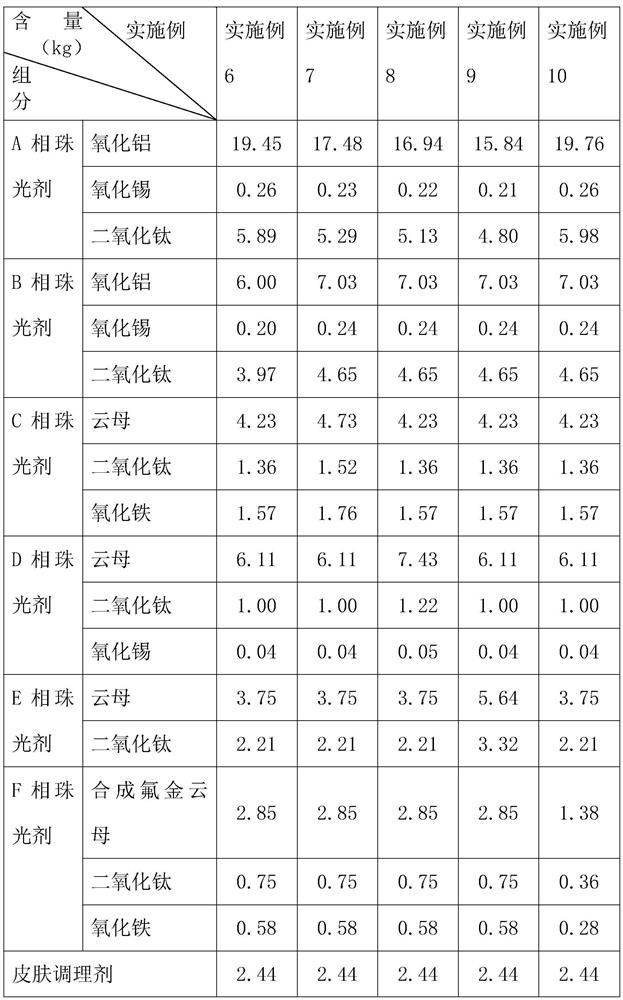

[0065] The difference between Examples 6-10 and Example 1 is that the raw material ratio of highlights is different, and the proportion of each component in the pearlescent agent of each phase in the pearlescent agent of the corresponding phase remains unchanged, see Table 2 for details.

[0066] Table 2

[0067]

[0068]

[0069] The difference between Examples 11-17 and Example 1 is that the raw material ratio of highlights is different, and the proportion of pearlescent agents of each phase in highlights remains unchanged, see Table 3 and Table 4 for details.

[0070] table 3

[0071]

[0072]

[0073]

[0074] Table 4

[0075]

[0076]

Embodiment 18

[0078] The difference between Example 18 and Example 1 is that the content of the A-phase pearlescent agent in this example is 18.85kg, and at the same time, this example also includes 5kg of regulator, which includes caprylic triglyceride and gold foil powder, The mass ratio of caprylic capric triglyceride to gold leaf powder is 3.2:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com