Flat coupling ridge waveguide semiconductor laser

A ridge waveguide and semiconductor technology, applied in the field of semiconductor laser devices, can solve the problems of high cavity surface power density, optical cavity surface catastrophe, narrow mode field area, etc., and achieve the goal of improving laser output power, good beam quality, and reducing power density Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

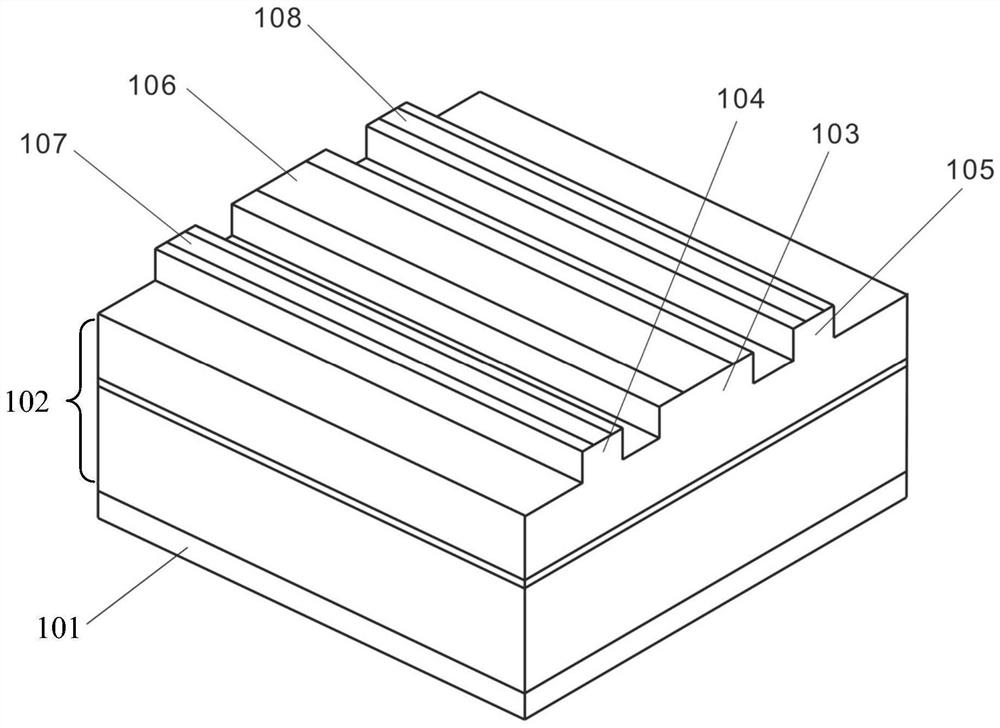

[0029] like figure 1 As shown, in this embodiment, a slab-coupled ridge waveguide semiconductor laser is specifically provided, aiming to further increase the total laser output power under the premise of maintaining better beam quality through optimization and improvement of the semiconductor laser. In this embodiment, a 976nm semiconductor laser is used, and the 976nm semiconductor laser mainly includes: a common electrode 101 and an epitaxial layer 102 that are stacked and arranged in sequence.

[0030] Three ridge waveguides are provided on the top of the epitaxial layer 102, respectively the first ridge waveguide 103, the second ridge waveguide 104 and the third ridge waveguide 105, wherein the first ridge waveguide 103 is a wide ridge waveguide and the second ridge waveguide 104 and The third ridge waveguide 105 is a narrow ridge waveguide, and the width of the narrow ridge waveguide is smaller than the width of the wide ridge waveguide. In this embodiment, the second r...

Embodiment 2

[0036]In this embodiment, a slab-coupled ridge waveguide semiconductor laser is specifically provided, aiming to further increase the total output power of the laser on the premise of maintaining better beam quality through optimization and improvement of the semiconductor laser. In Embodiment 1 On the basis, the design of the semiconductor laser is as follows:

[0037] Three ridge waveguides are provided on the top of the epitaxial layer 102, respectively the first ridge waveguide 103, the second ridge waveguide 104 and the third ridge waveguide 105, wherein the first ridge waveguide 103 is a wide ridge waveguide and the second ridge waveguide 104 And the third ridge waveguide 105 is a narrow ridge waveguide, the width of the narrow ridge waveguide is smaller than the width of the wide ridge waveguide. In this embodiment, the second ridge waveguide 104 and the third ridge waveguide 105 are located on both sides of the first ridge waveguide 103 and distributed asymmetrically. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com