Milling process-oriented carbon emission chemical calculation method and system

A carbon emission and milling technology, applied in the field of carbon emission quantification calculation method and system, to achieve the effect of accurate calculation results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

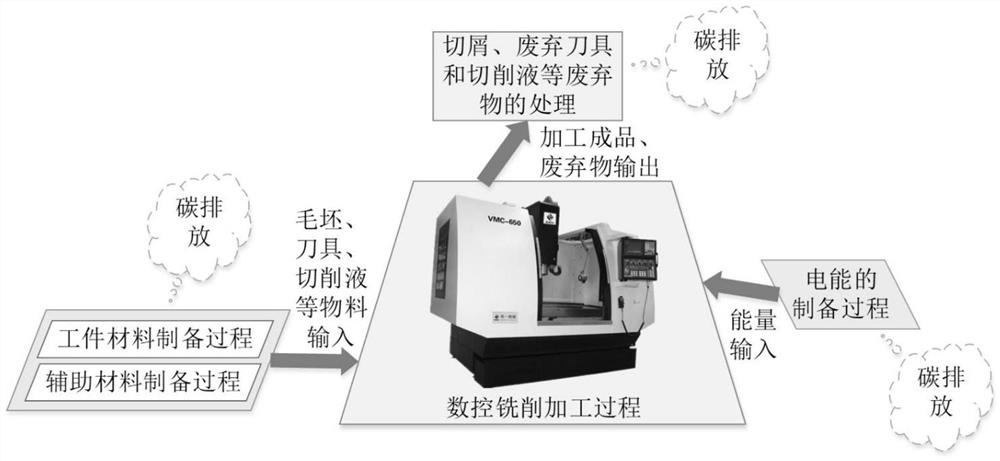

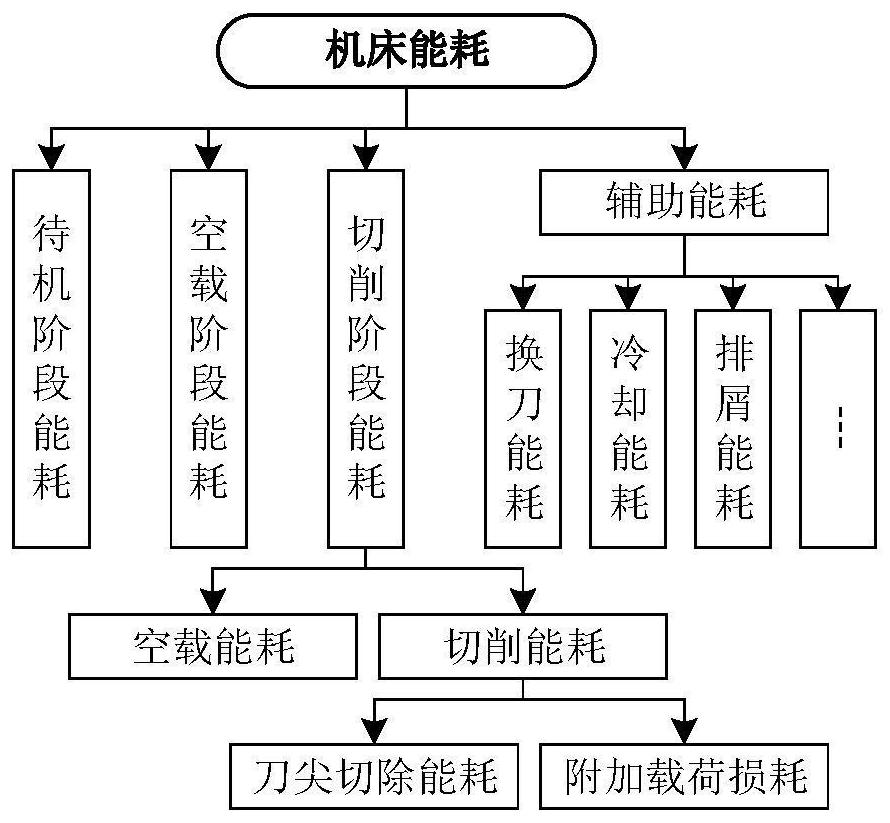

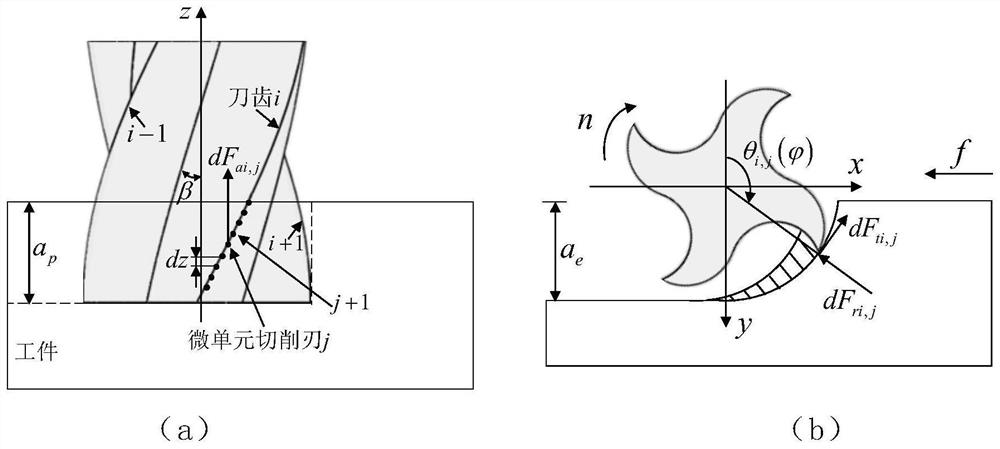

Method used

Image

Examples

preparation example Construction

[0088] Preparation of workpiece materials Carbon emissions CE pchip Calculated as follows:

[0089] CE pchip =ΔV×ρ×EF pchip

[0090] where ΔV is the volume of workpiece material removed / m 3 ; ρ is the density of the workpiece material / kg m -3 ;EF pchip is the carbon emission factor of workpiece material preparation / kgCO 2 kg -1 .

[0091] (2) Carbon emissions from tool preparation

[0092] Preparation of knives carbon emissions CE ptool Calculated as follows:

[0093]

[0094] Among them, t c is the cutting time / min of the tool under specific cutting conditions; T t is the tool durability / min of the tool under specific cutting conditions; N is the number of times the tool can be sharpened; m t is the mass of the tool / g; EF ptool is the carbon emission factor of tool production / kgCO 2 kg -1 .

[0095] Among them, the tool life of each machining is estimated by the Taylor tool life equation as follows:

[0096]

[0097] Among them, C V ,K V ,q V ,y V ...

Embodiment

[0241] The technical solutions of the present invention will be described below in conjunction with specific examples.

[0242] Collect the idling power and standby power data of the machine tool spindle with increasing gradient, and compare the power data to obtain the net power of the machine tool spindle idling at different speeds. In order to ensure the accuracy of the experiment, 20 sets of power data were collected under each set of experimental parameters to obtain the average value. The obtained experimental data are shown in Table 1.

[0243] Table 1 VDL-850A spindle speed and net power comparison table

[0244]

[0245] From the experimental data, it can be seen that the rotational power of the spindle increases with the increase of the rotational speed in the form of a piecewise function, which is consistent with the established model of the rotational power of the spindle. Therefore, the collected spindle power data is grouped and processed using IBM SPSS Statist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com