Method for analyzing crashworthiness of composite material reinforced whole vehicle main transmission path force-bearing component

A technology of composite materials and analysis methods, which is applied in the field of crashworthiness analysis of load-bearing components of the main transmission path of composite materials to enhance the vehicle, and achieves the effect of significant effect, controllable cost, and guarantee of resistance to deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

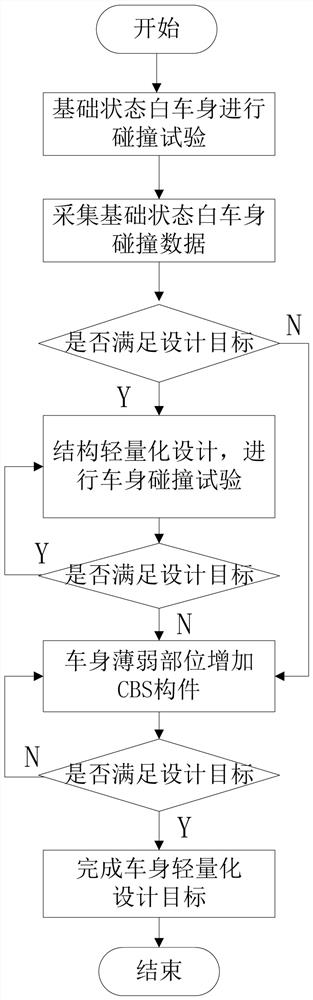

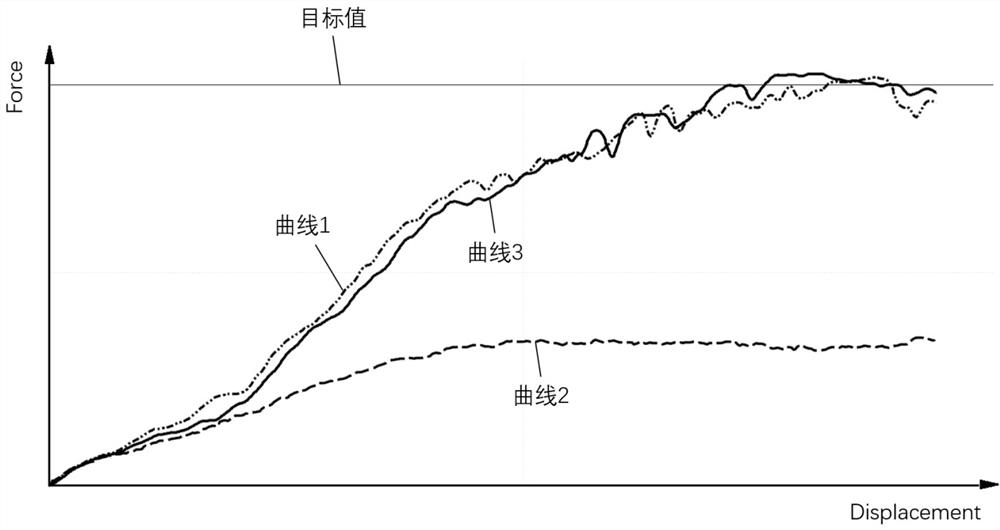

[0057] Specific example, the actual design case of recovering the original roof compressive strength of the whole vehicle by adding composite material reinforcement components at its weak position after the B-pillar of a certain model is lightweight: Crashworthiness analysis, the curve of loading force and displacement is as follows figure 2 Shown in curve 1.

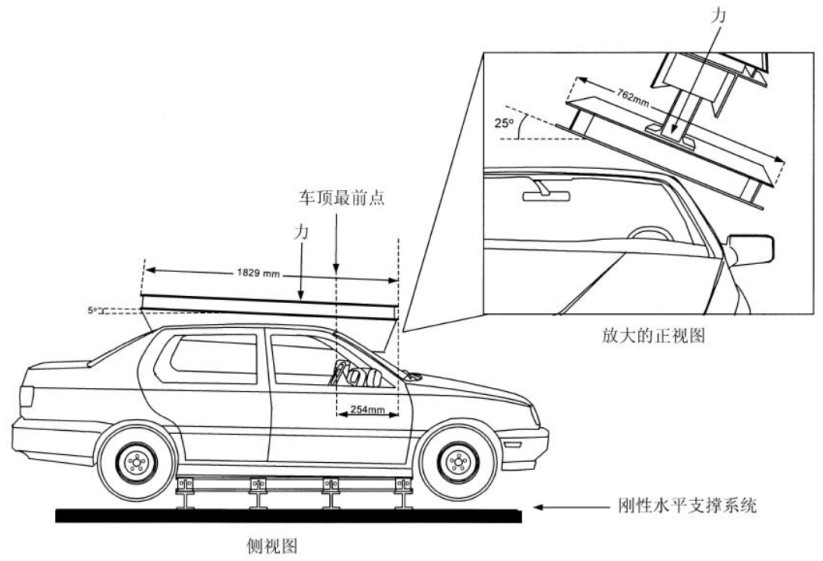

[0058] (2) Obtain the analysis results of step 3, figure 2 Curve 1 in the curve 1 judges whether the result meets the design target. The design target generally refers to a certain amount exceeding the requirements of the regulations. The design regulations of the present invention are "GB26134 Passenger Car Roof Compressive Strength", and the required scope of the regulations is: The loaded load is 3.0 times the curb weight of the vehicle, and the movement of the lower surface of the loading device should not be greater than 127 mm. Taking the curb weight of a vehicle as an example of 1.6T, the design target of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com