Static pressure prestressed pipe pile construction method

A prestressed pipe pile and construction method technology, applied in sheet pile wall, foundation structure engineering, construction and other directions, can solve the problems of affecting the construction process, prone to broken piles, affecting the verticality and quality of formed pipe piles, etc. Welding quality, avoiding pile breakage, improving mechanical properties and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

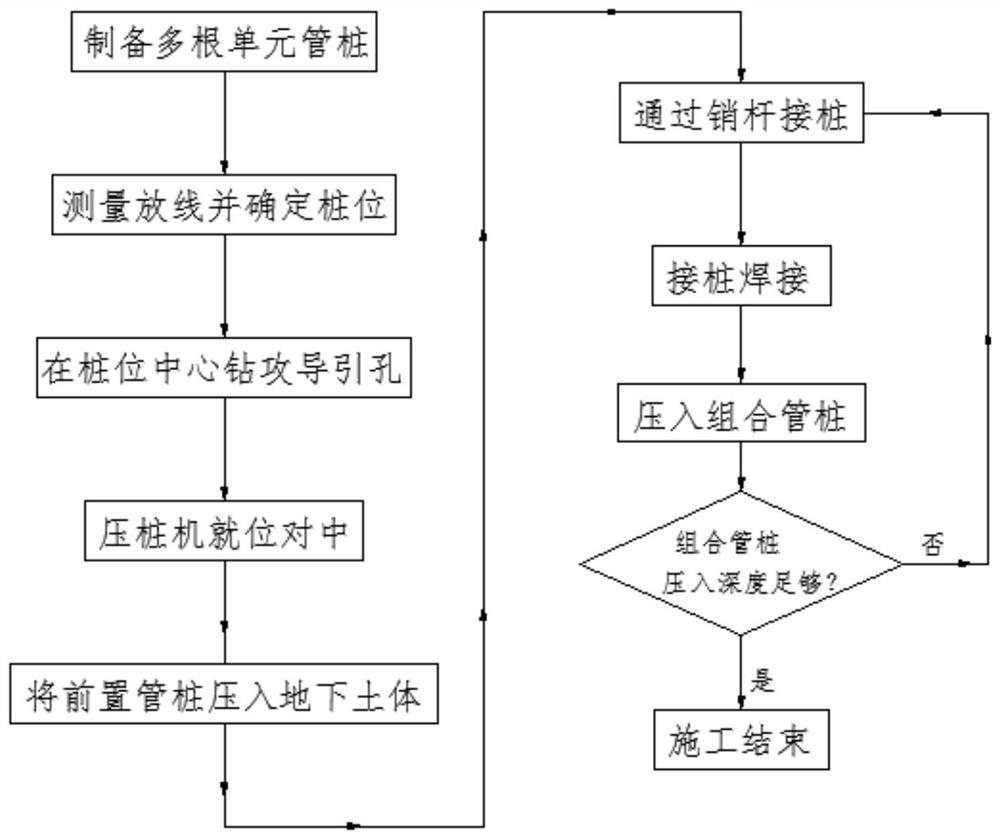

[0026] like figure 1 Shown, the invention provides a kind of static pressure prestressed pipe pile construction method, comprise 1, a kind of static pressure prestressed pipe pile construction method, it is characterized in that: comprise the following steps:

[0027] Step 1: Prepare a plurality of unit pipe piles, flange rings are fixedly connected to both ends of the unit pipe piles, and a plurality of positioning holes are arranged on the flange rings;

[0028] Step 2: Measurement and setting out: carry out measurement and setting out according to the design drawings and review, and determine the pile position;

[0029] Step 3: Drill and tap pilot holes in the center of the pile position in Step 2;

[0030] Step 4: Provide a pile driver, move the pile driver to the pile position in step 2, align the drill pipe with the pile po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com