High-strength stainless steel wire for interventional medical treatment and preparation method thereof

A stainless steel wire, high-strength technology, used in the field of medical equipment, can solve problems affecting the corrosion of stainless steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

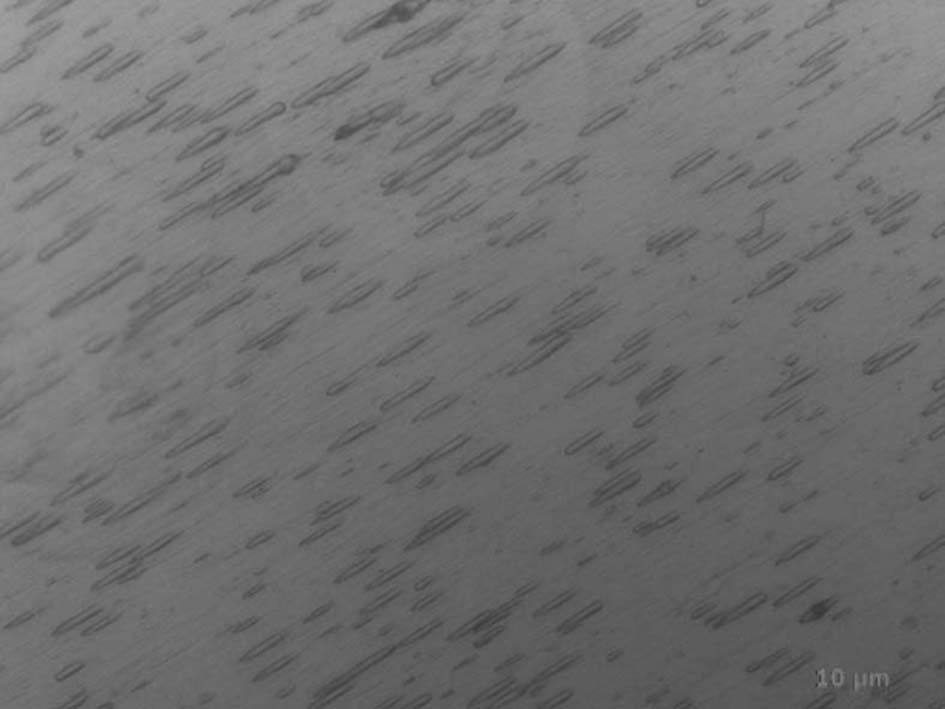

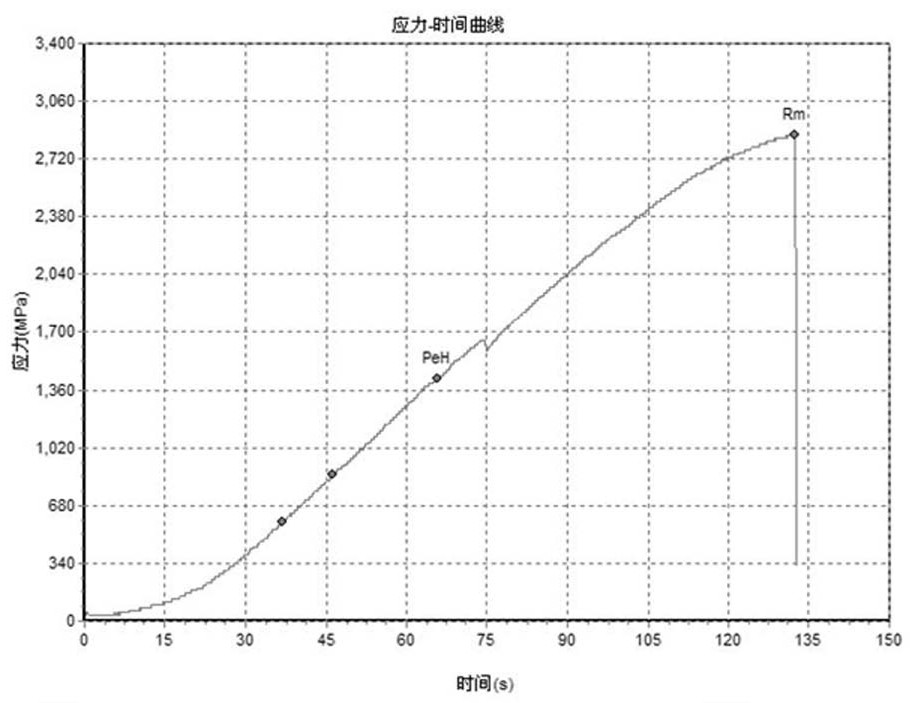

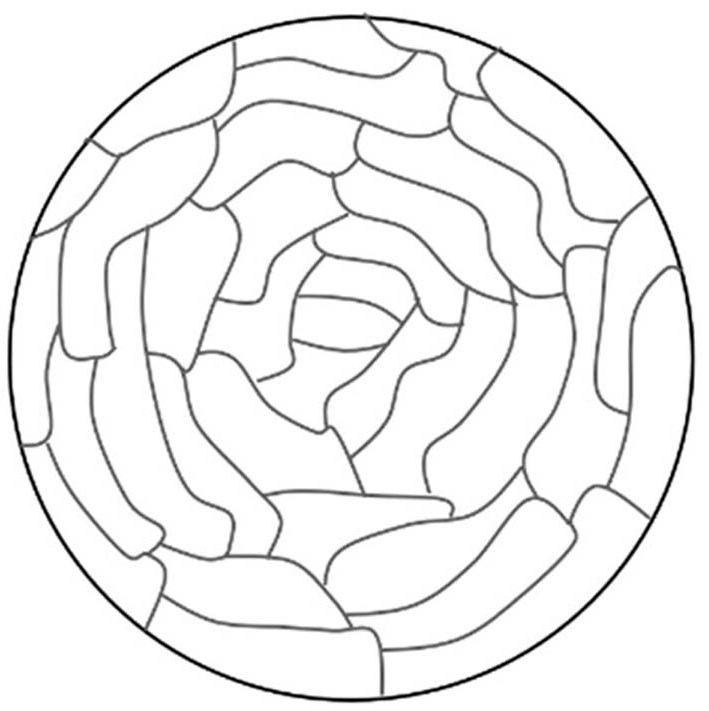

Image

Examples

Embodiment

[0051] Example: Examples 1-10 are high-strength austenitic stainless steel wires produced by controlled smelting and processing using the components and preparation methods of the present invention, and their chemical compositions are shown in Table 1.

[0052] Table 1: Composition and performance parameters of Examples 1-10.

[0053] Example number 1 2 3 4 5 6 7 8 9 10 La+Ce% 0.02 0.11 0.48 0.22 0.14 0.37 0.26 0.19 0.43 0.04 Y% 0.02 0.55 0.31 0.14 0.23 0.05 0.46 0.73 0.09 0.98 P % 0.005 0.04 0.017 0.023 0.006 0.035 0.05 0.009 0.016 0.02 S % 0.28 0.01 0.07 0.05 0.25 0.06 0.21 0.17 0.13 0.12 N % 0.07 0.03 0.06 0.05 0.08 0.02 0.01 0.03 0.04 0.01 Ni % 7.8 15 10.1 12.1 9.4 14.6 11.7 9.2 10.5 8.1 Cr% 17 20 18 16 14 19.7 20 17 18 19 Mn% 0.01 1.9 0.53 1.2 0.19 1.87 1.04 1.8 0.07 1.6 Si% 0.01 0.99 0.51 0.05 0.98 0.79 0.95 0.03 0.46 0.25 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com