A kind of water-based paint and its preparation method and application

A water-based coating and water-based coating technology, applied in the field of coatings, can solve the problems of reducing coating film hardness, chemical resistance, complex composition, and high toxicity of monomers, and achieve the effect of improving stability, simple raw materials, and improving shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

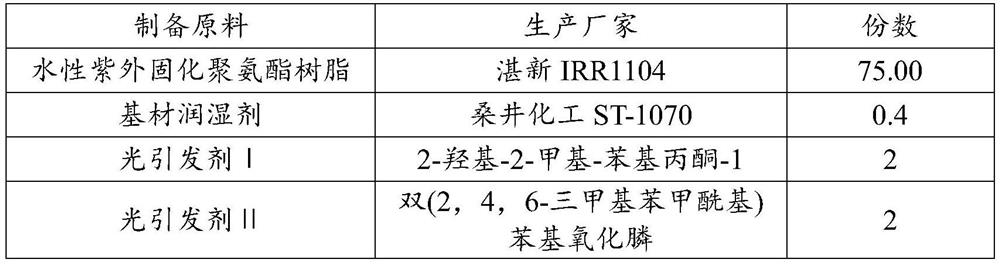

[0078] The water-based paint of the present embodiment is prepared from the preparation raw materials shown in Table 1:

[0079] The preparation raw material of the water-based paint of table 1 the present embodiment

[0080]

Embodiment 2

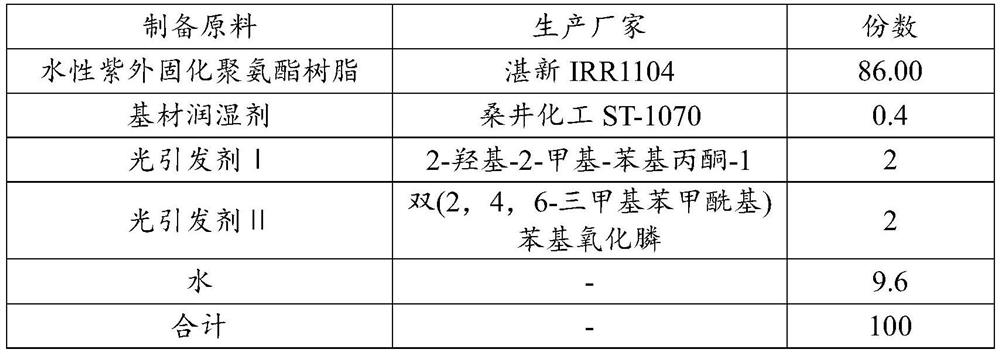

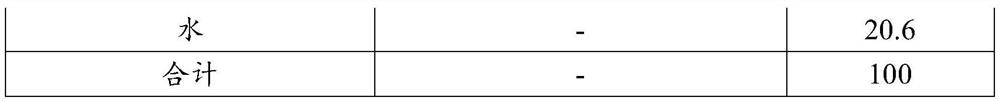

[0082] The water-based paint of the present embodiment is prepared from the preparation raw materials shown in Table 2:

[0083] The preparation raw material of the water-based paint of table 2 the present embodiment

[0084] Preparation of raw materials Manufacturer number of copies Waterborne UV Curable Polyurethane Resin Wuxing Chemical WU3604 95.00 Substrate wetting agent Evonik TegoWet270 0.4 Photoinitiator I 2-Hydroxy-2-methyl-phenylacetone-1 1.5 Photoinitiator II 1-Hydroxy-cyclohexylbenzophenone 1 water - 2.1 total - 100

PUM

| Property | Measurement | Unit |

|---|---|---|

| Functional group degree | aaaaa | aaaaa |

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com