Isolated packaging self-compensation resonance pressure sensitive chip probe and packaging method thereof

A sensitive chip, self-compensating technology, applied in the measurement of fluid pressure, decorative arts, measurement devices, etc., can solve the problems of decreased measurement accuracy and long-term stability, affecting measurement accuracy and application range, low Q value, etc. The effect of stability, improved accuracy, and increased reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

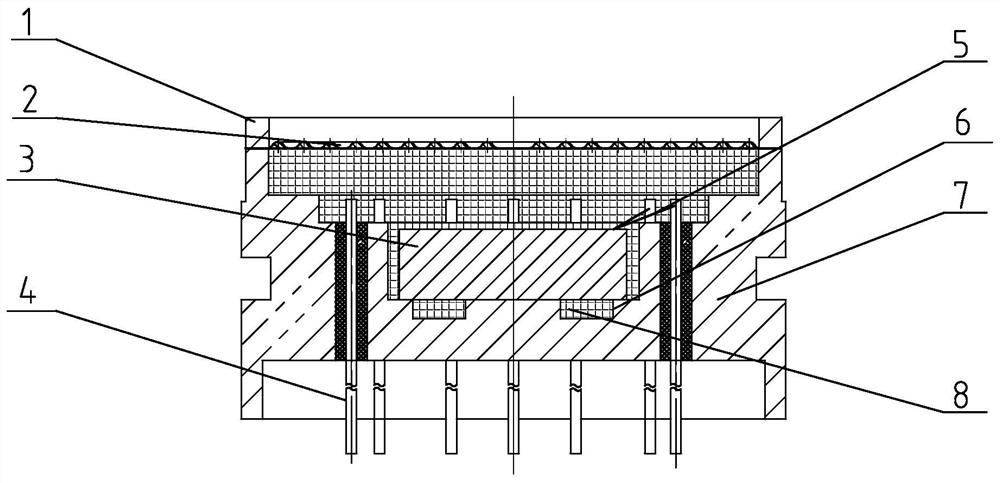

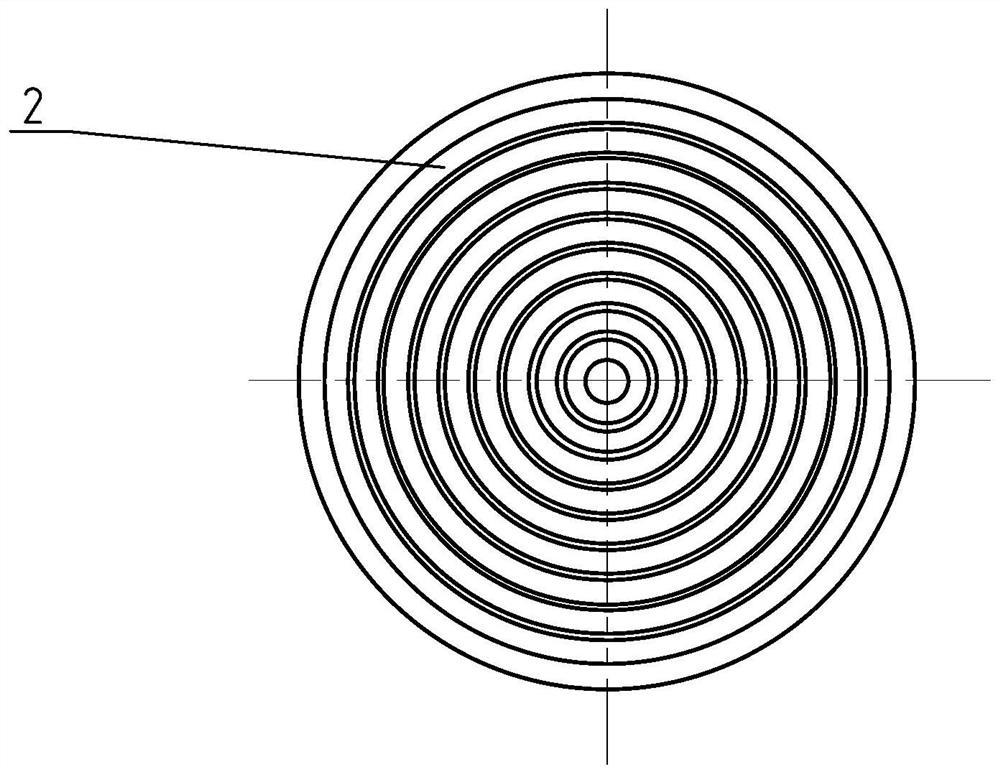

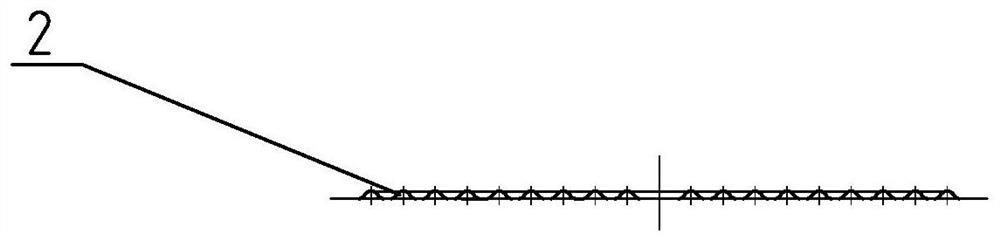

[0057] Specific implementation mode one: combine Figure 1 to Figure 8 Describe this embodiment mode, an isolated package self-compensation resonant pressure sensitive chip probe of this embodiment mode, which includes a pressure ring 1, a corrugated diaphragm 2, a silicon resonant pressure sensitive chip 3, a Kovar pin 4, and an electrode bonding wire 5. Two probe medium transmission channels 6, sealing tube base 7 and isolation medium 8,

[0058] The upper end surface of the sealing tube base 7 is a corrugated diaphragm contact surface 701, and a stepped groove is provided on the corrugated diaphragm contact surface 701, the upper stepped surface of the stepped groove is the lead hole surface 704, and the lower stepped surface is the chip bonding surface 702, two probe medium transmission channels 6 are opened on the chip bonding surface 702, a plurality of lead holes 703 are vertically opened on the lead hole surface 704, and the middle and upper part of the outer cylindric...

specific Embodiment approach 2

[0064] Specific implementation mode two: combination Figure 4 To illustrate this embodiment, a pressure-sensitive via hole 3031 is provided between two adjacent stress isolation layers 303 and directly below the pressure silicon-based substrate 3021-1 in this embodiment. Such arrangement enables the medium pressure to be transmitted to the resonant layer 302 accurately. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0065] Specific implementation mode three: combination Figure 4 To illustrate this embodiment, a temperature-sensing via hole 3032 is provided between two adjacent stress isolation layers 303 and directly below the temperature silicon-based substrate 3021-2 in this embodiment. Such setting facilitates the transmission of pressure to the silicon-based substrate 3021 and then to the resonant layer 302 to achieve the purpose of pressure sensing. Other compositions and connections are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com