A bagged material handling and conveying device

A conveying device and material technology, which is applied in the direction of transportation and packaging, conveyors, conveyor objects, etc., can solve problems such as difficult to meet the needs of bagged material handling and delivery, bagged material delivery, packaging bag scratches, etc., to improve handling Speed, reduce concentrated force, reduce the effect of damage problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

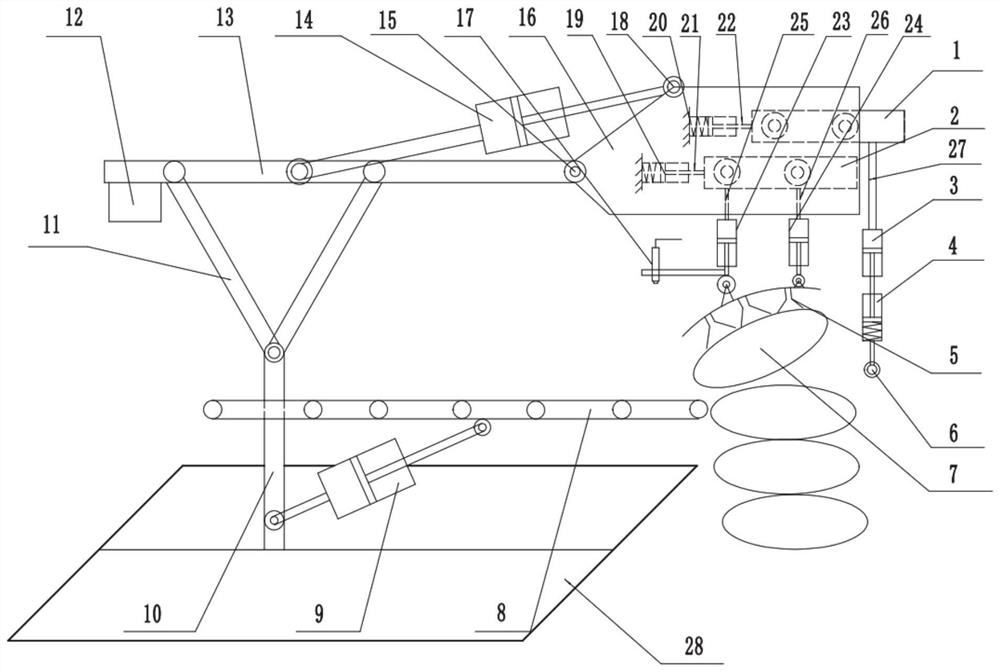

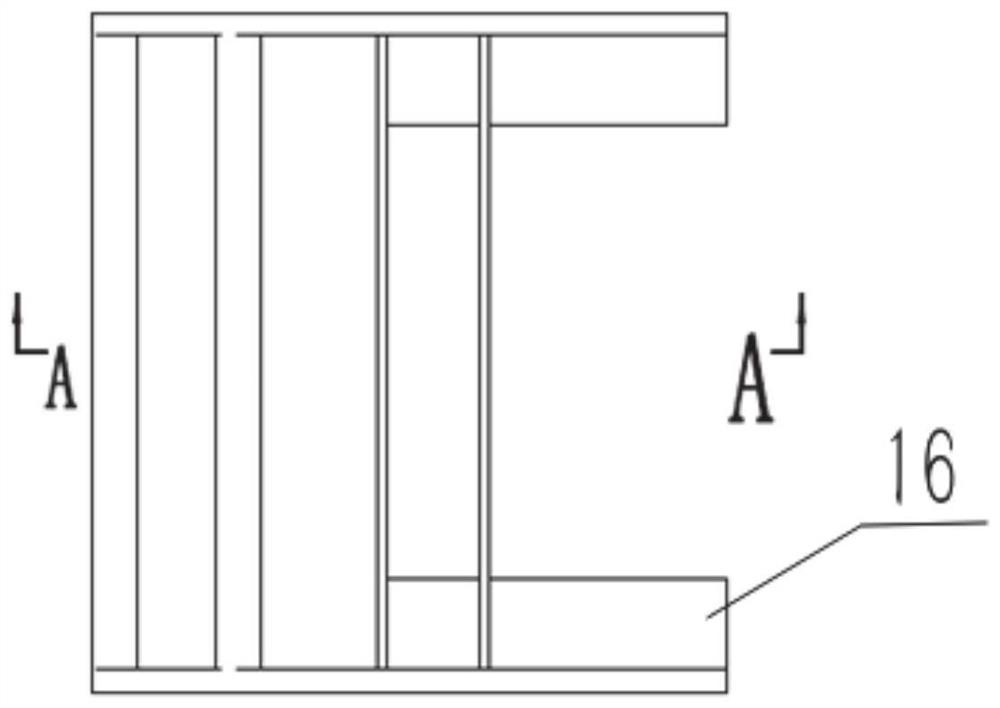

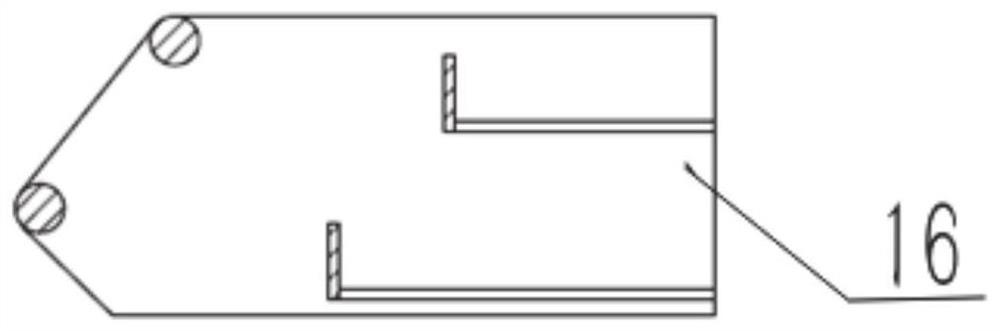

[0030] In a typical embodiment of the present invention, as Figure 1-Figure 5 As shown, a bagged material handling and conveying device is proposed.

[0031] Aiming at the problem that the bagged material 7 is inconvenient to be transported, loaded and transported, and the bagged material 7 is easily damaged, a bagged material 7 handling and conveying device is provided, which uses multiple suction cups to form a suction cup assembly 5, and grabs the bagged material 7 on the suction cups. The suction cup maintains a large contact area with the bagged material 7, reducing the concentrated force at the adsorption position, thereby reducing the damage of the bagged material 7 during the handling process and improving the material handling speed.

[0032] The bagged material 7 handling and conveying device mainly includes a mobile base 28, a mechanical arm, a conveyor belt 8 and a handling structure. The mechanical arm is installed on the mobile base 28, and changes its position ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com