Electromagnetic valve coil automatic assembling equipment and assembling method

A solenoid valve coil, automatic assembly technology, used in assembly machines, welding equipment, metal processing equipment, etc., can solve the problems of damage to the coil body and upper cover, increased transportation costs, low efficiency, etc., to save driving sources and improve efficiency. , Guaranteed quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0081] Said cylinder, electric cylinder etc. of the present invention are all provided with connecting plate at the output end, are used for connecting next moving part, or are used for accepting objects such as coil, cover, loam cake, shrapnel, shell. Moreover, clamping portions are provided at the ends of the jaw cylinders.

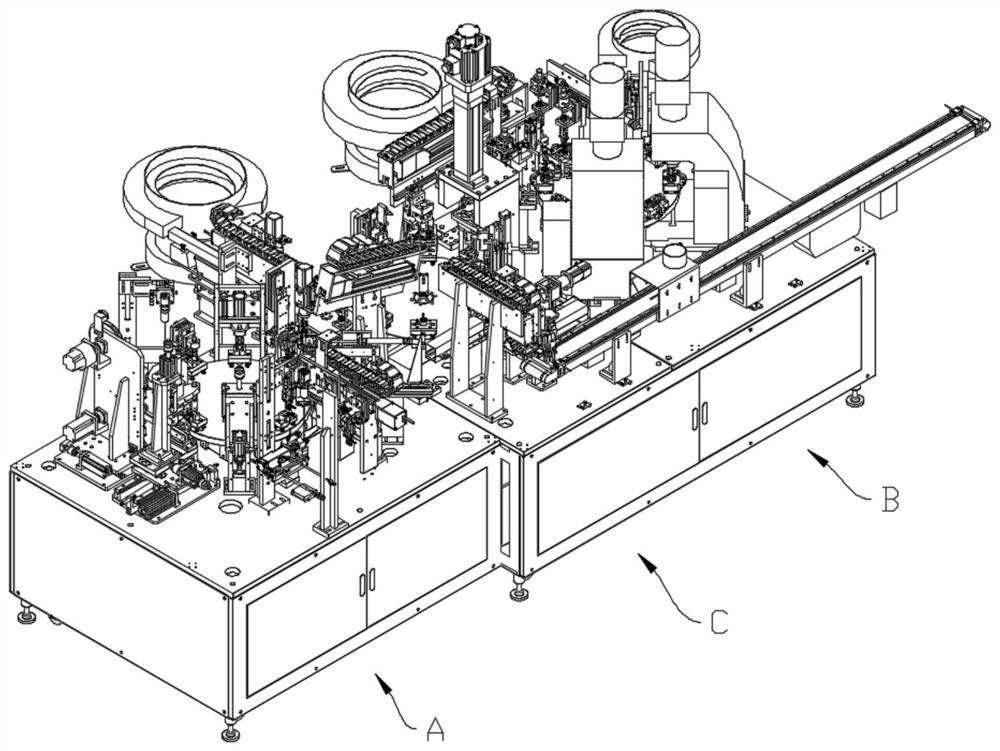

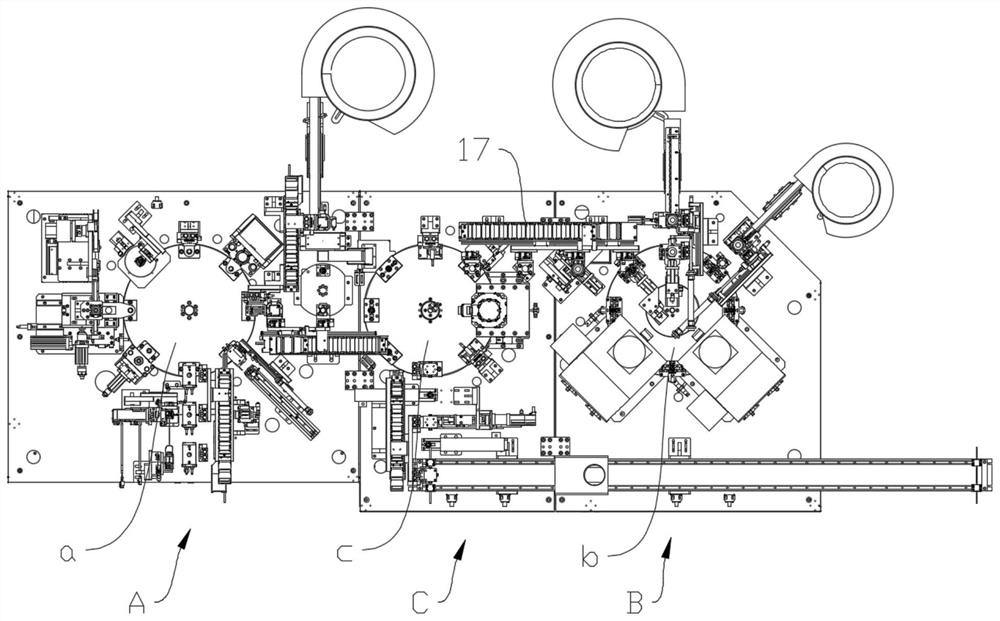

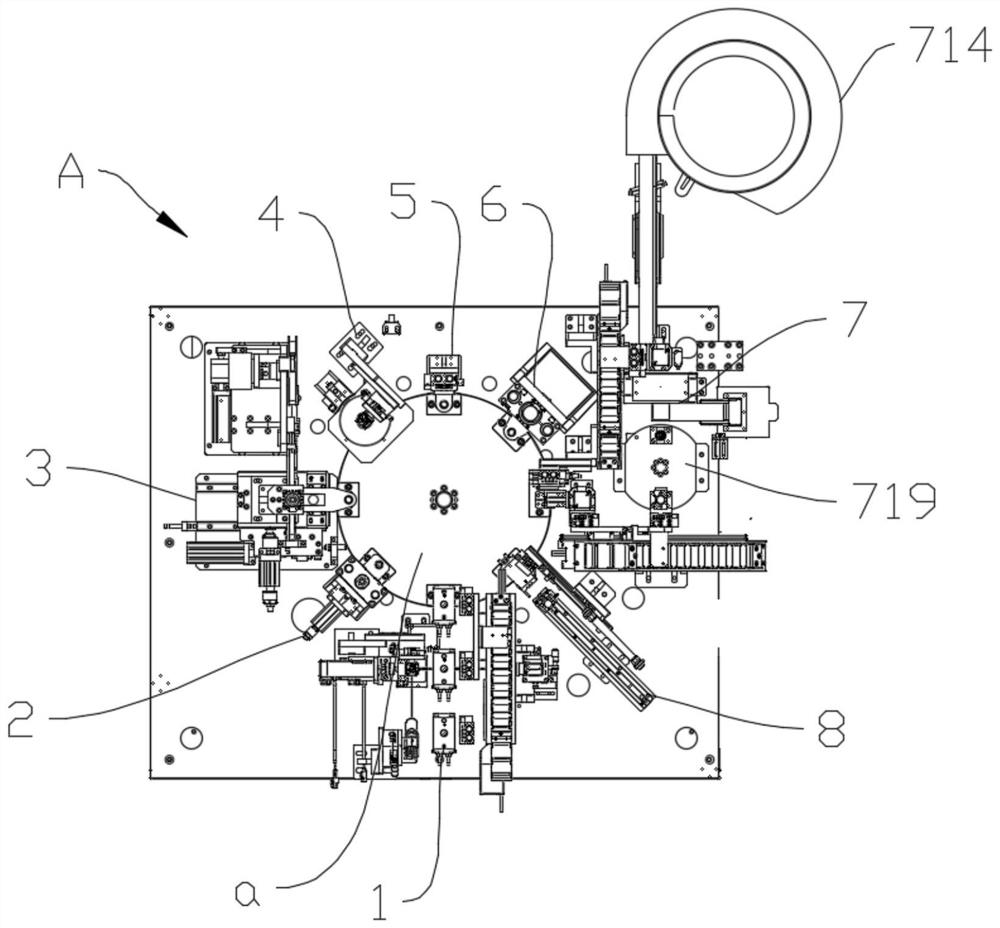

[0082] Such as Figure 1-2 As shown, an automatic solenoid valve coil assembly equipment includes a coil welding test mechanism A, an upper cover shrapnel combined pressure riveting mechanism B and a coil shell upper cover combined pressing mechanism C, and a coil welding and testing mechanism A’s coil casing station 7 The assembled coil is delivered to the coil feeding station 18 of the upper cover combination pressing mechanism C of the coil shell, and the upper cover discharge station 16 of the upper cover shrapnel combination pressure riveting mechanism B is used to deliver the assembled upper cover to the coil casing The upper cover feeding statio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com