Multi-station feeding conveying equipment and storage yard

A conveying equipment and multi-station technology, applied in conveyors, conveyor objects, mechanical conveyors, etc., can solve the problems of refractory brick bonding damage, affecting the normal production of lime kiln, stuck and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

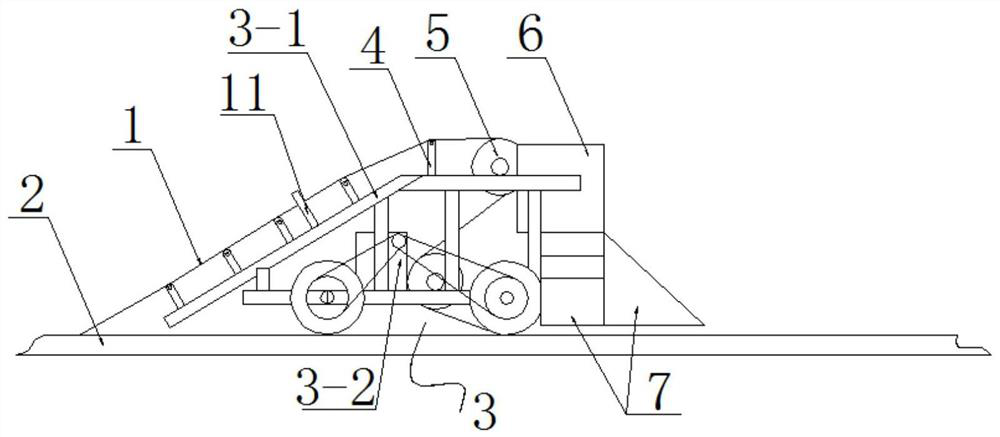

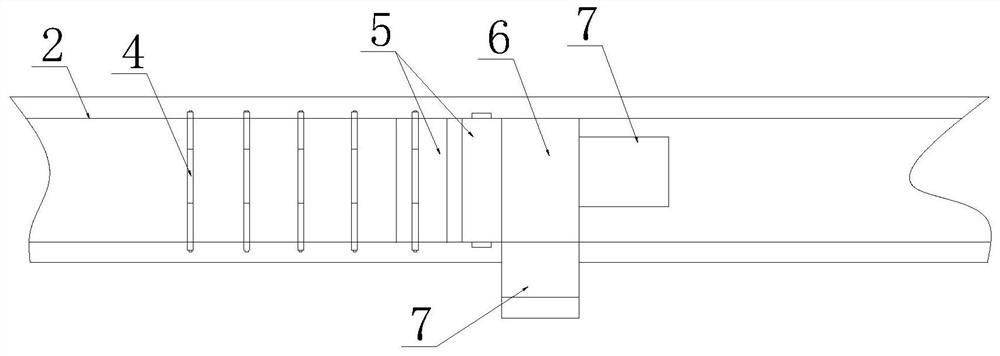

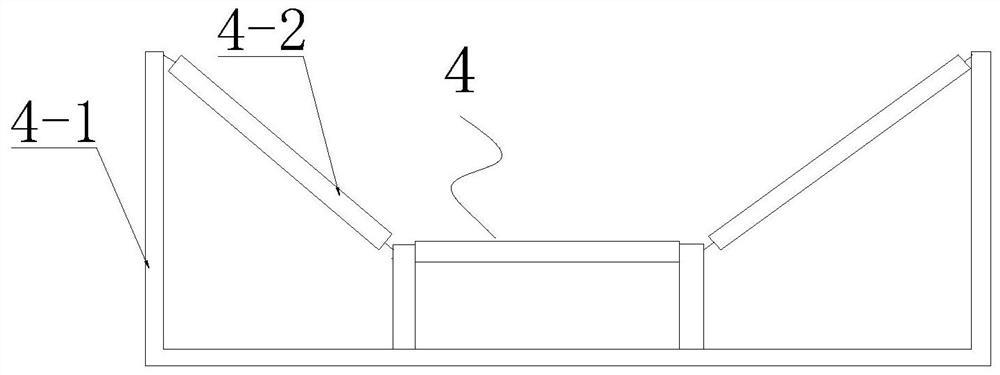

[0033] see Figure 1 to Figure 5 As shown, a conveying equipment for multi-station feeding includes a conveying device 1, which is a belt conveying device, and guide rails 2 arranged in parallel are distributed on both sides of the conveyor belt of the conveying device 1, and the two guide rails 2 A feeding trolley 3 is arranged on it, and the said feeding trolley 3 comprises a vehicle frame 3-1 and a trolley driving mechanism 3-2, and the vehicle frame 3-1 adopts a steel frame to form, and the lower end of the vehicle frame 3-1 is provided with the The wheels that guide rail 2 matches, the lower end of vehicle frame 3-1 is provided with two front wheels and two rear wheels. The trolley driving mechanism 3-2 is used to drive the vehicle frame 3-1 to move back and forth along the guide rail. The trolley driving mechanism 3-2 includes a motor, a transmission chain, a main transmission tooth and a slave transmission tooth. The transmission teeth are arranged on the output shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com