engine maintenance stand

A maintenance rack and engine technology, applied in the field of aviation machinery, can solve the problems of a single maintenance rack, occupy a large space, and do not have a transfer engine, etc., and achieve the effect of reducing the transfer process, compact structure, and reducing the space occupied.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

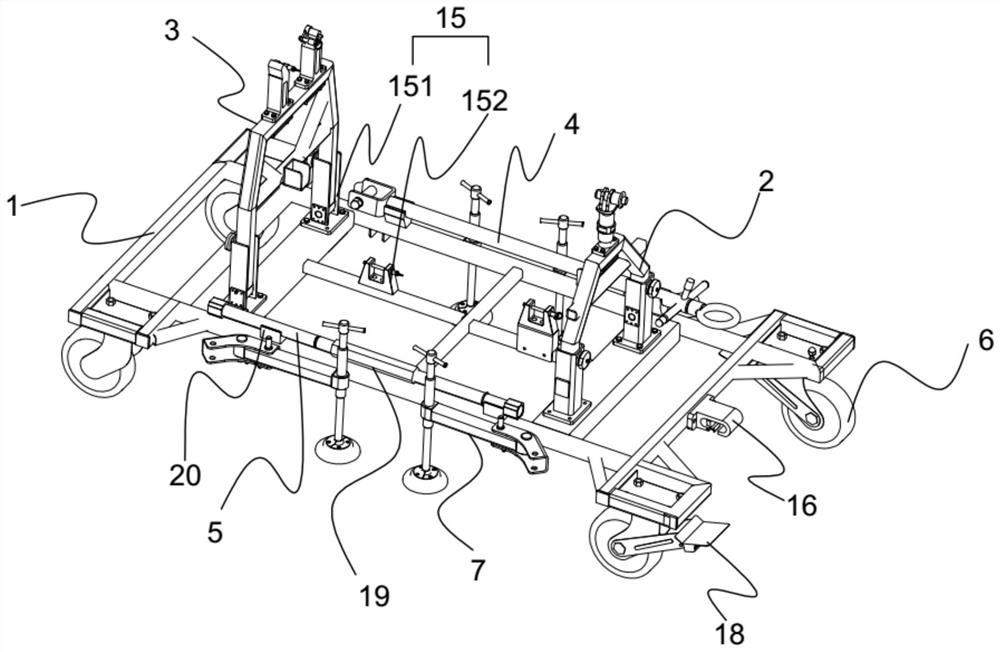

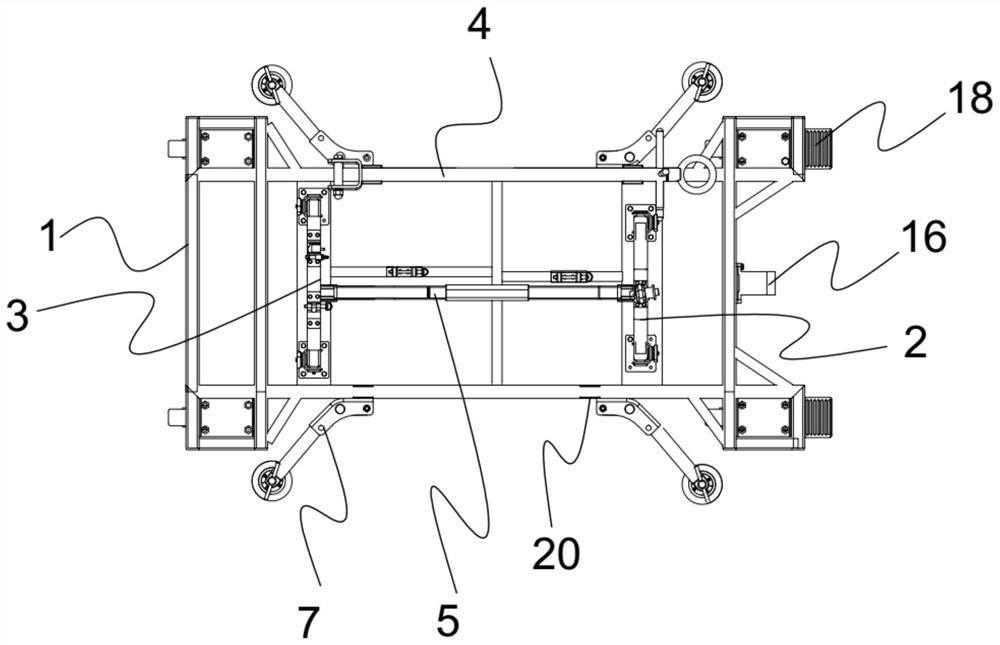

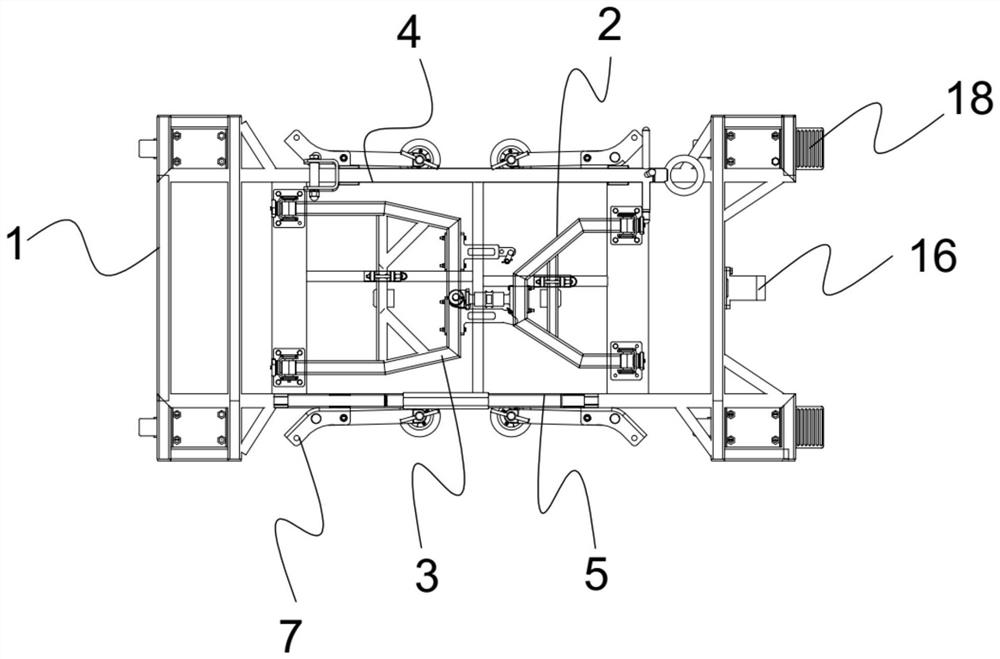

[0019]ReferFigure 1-6The embodiment of the present invention will be specifically described.

[0020]An engine maintenance rack, including a bottom plate 1, a first door frame 2, a second door frame 3, a traction rod 4, and a rod 5, and a roller 6 and a leg assembly 7 are provided on the bottom plate 1. The roller 6 is provided at both ends of the bottom plate 1, the leg assembly 7 disposed on both sides of the bottom plate 1, the leg assembly 7 including the crossbar 71, vertical rod 72, and the length of the vertical rod 72. The rotary handle 73 is hinged on the bottom plate 1, and a threaded sleeve is provided at the other end of the crossbar 71, which is connected to the threaded sleeve. The rotating handle 73 is disposed at the top of the vertical rod 72, and is also provided with a positioning groove 74 for positioning the crossbar 71 on the bottom plate 1, in which the positioning slot 74 and the A positioning hole 75 is provided in a position corresponding to the horizontal bar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com