Seed coating agent for promoting germination and seedling formation of leguminous seeds in saline-alkali soil and preparation method of seed coating agent

A technology for saline-alkali soil and seeds, which is applied in the fields of seed coating/seed dressing, botanical equipment and methods, biocides, etc., can solve problems such as inapplicability, and achieve the effects of product stability, small equipment investment and uniform coating.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

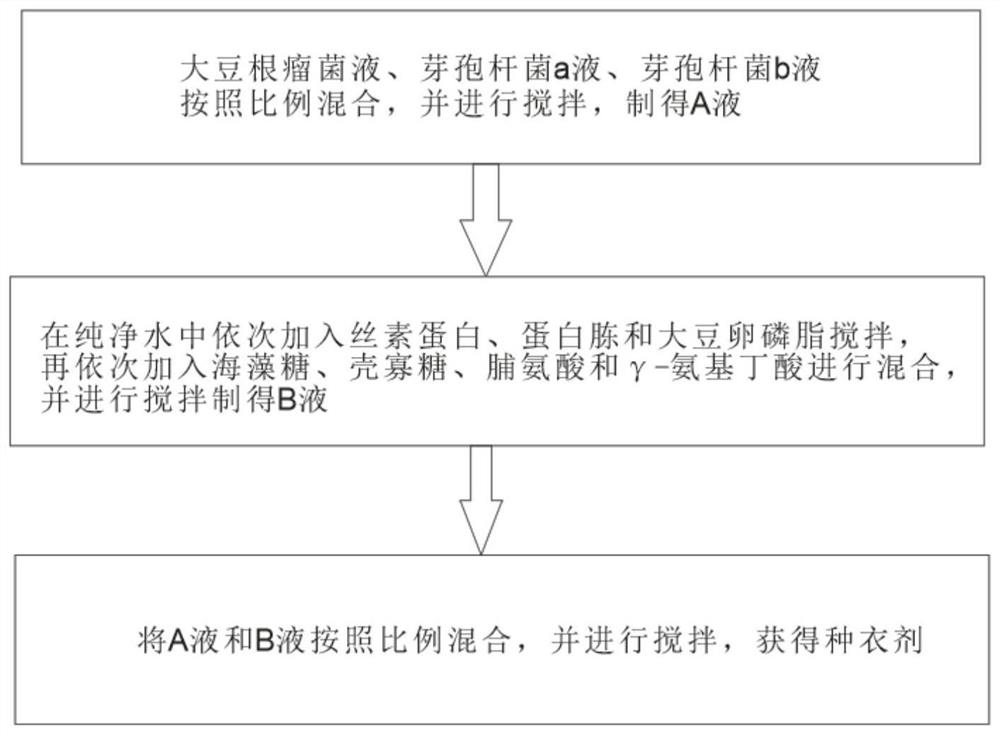

Method used

Image

Examples

Embodiment 1

[0053] Weigh the corresponding raw materials according to the requirements of each component for later use; among them, soybean rhizobia liquid: 250g; Bacillus a liquid: 200g; Bacillus b liquid: 150g; silk fibroin: 60g; peptone: 40g; Sugar: 120g; Chitooligosaccharide: 1g; Proline: 0.1g; γ-aminobutyric acid: 0.3g, purified water: 168.6g; : Mix in a ratio of 4:3, and stir for 2 minutes at a speed of 150 rpm to prepare liquid A; then weigh 168.6 g of water, add silk fibroin, peptone and soybean lecithin in sequence and stir for 30 minutes at a speed of 150 rpm, Then add trehalose, chitosan oligosaccharide, proline and γ-aminobutyric acid in sequence to mix, and stir for 30 minutes at a speed of 200 rpm to prepare liquid B; finally, liquid A and liquid B are mixed according to the ratio of 7:3 Proportionally mixed and stirred for 20 minutes at a speed of 200 rpm to obtain the seed coating agent.

Embodiment 2

[0055] Weigh the corresponding raw materials according to the requirements of each component for later use; among them, soybean rhizobia liquid: 300g; Bacillus a liquid: 240g; Bacillus b liquid: 180g; silk fibroin: 80g; peptone: 50g; Sugar: 150g; Chitooligosaccharide: 1.2g; Proline: 0.15g; γ-aminobutyric acid: 0.5g, purified water: 196.15g; Mix at a ratio of 5:4:3, and stir for 2 minutes at a speed of 200 rpm to prepare liquid A; then weigh 196.15 g of water, add silk fibroin, peptone and soybean lecithin in sequence and stir for 30 minutes at a speed of 150 rpm , and then add trehalose, chitosan oligosaccharide, proline and γ-aminobutyric acid in turn to mix, and stir for 30 minutes at a speed of 200 rpm to prepare liquid B; finally, liquid A and liquid B are mixed according to the ratio of 7:3 The ratio was mixed, and stirred for 20min at a speed of 200 rev / min to obtain the seed coating agent.

Embodiment 3

[0057] Weigh the corresponding raw materials according to the requirements of each component for later use; among them, soybean rhizobia liquid: 250g; Bacillus a liquid: 20g; Bacillus b liquid: 150g; silk fibroin: 60g; peptone: 40g; Sugar: 120g; Chitooligosaccharide: 1g; Proline: 0.1g; γ-aminobutyric acid: 0.3g, purified water: 168.6g; : Mix in a ratio of 4:3, and stir for 2 minutes at a speed of 150 rpm to prepare liquid A; then weigh 168.6 g of water, add silk fibroin, peptone and soybean lecithin in sequence and stir for 30 minutes at a speed of 150 rpm, Then add trehalose, chitosan oligosaccharide, proline and γ-aminobutyric acid in sequence to mix, and stir for 30 minutes at a speed of 200 rpm to prepare liquid B; finally, liquid A and liquid B are mixed according to the ratio of 7:3 Proportionally mixed, and stirred for 20min, the rotating speed is 200 rpm / min, to obtain the seed coating agent

[0058] Weigh the corresponding raw materials according to the requirements ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com