Concrete powder storage device

A technology of concrete powder and storage device, which is applied in the field of concrete powder tanks, can solve problems such as easy overflow of powder, and achieve the effect of reducing the possibility of overfilling and overflowing of powder.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

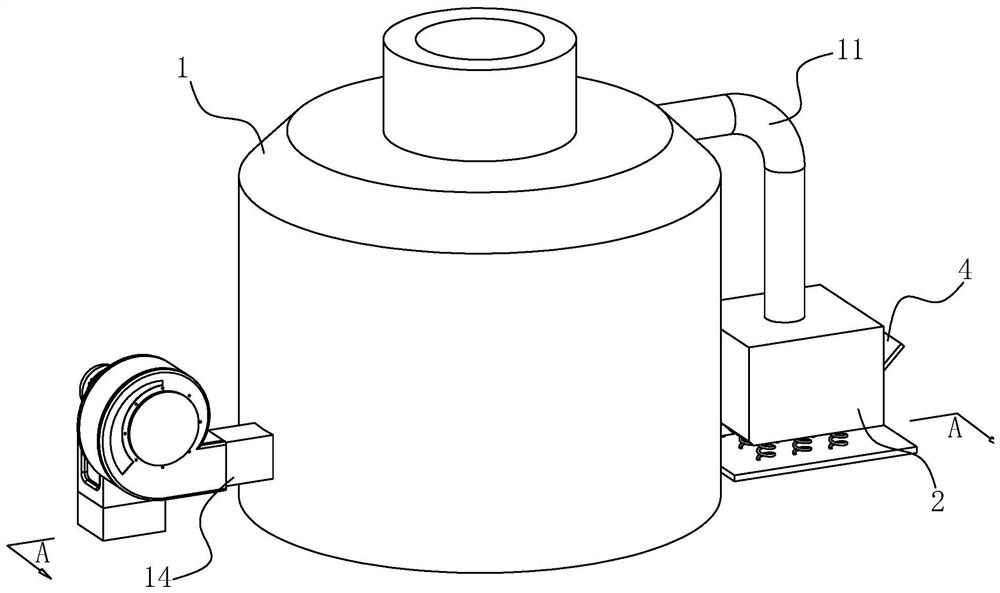

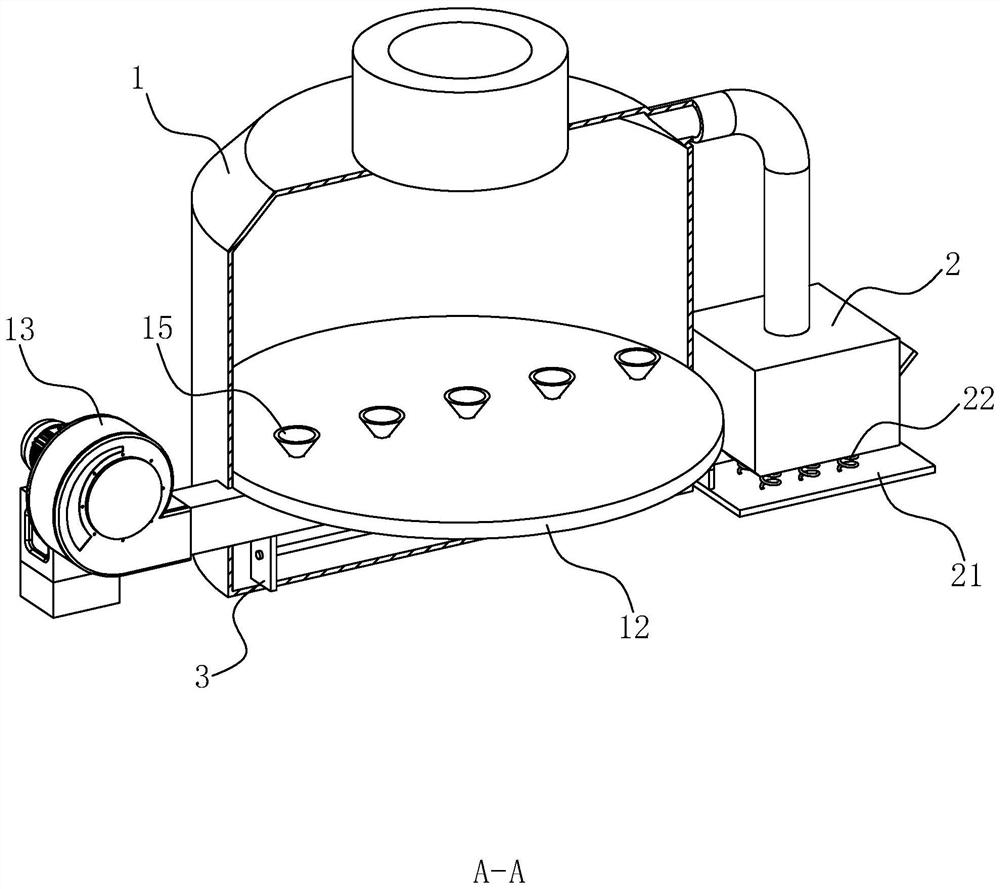

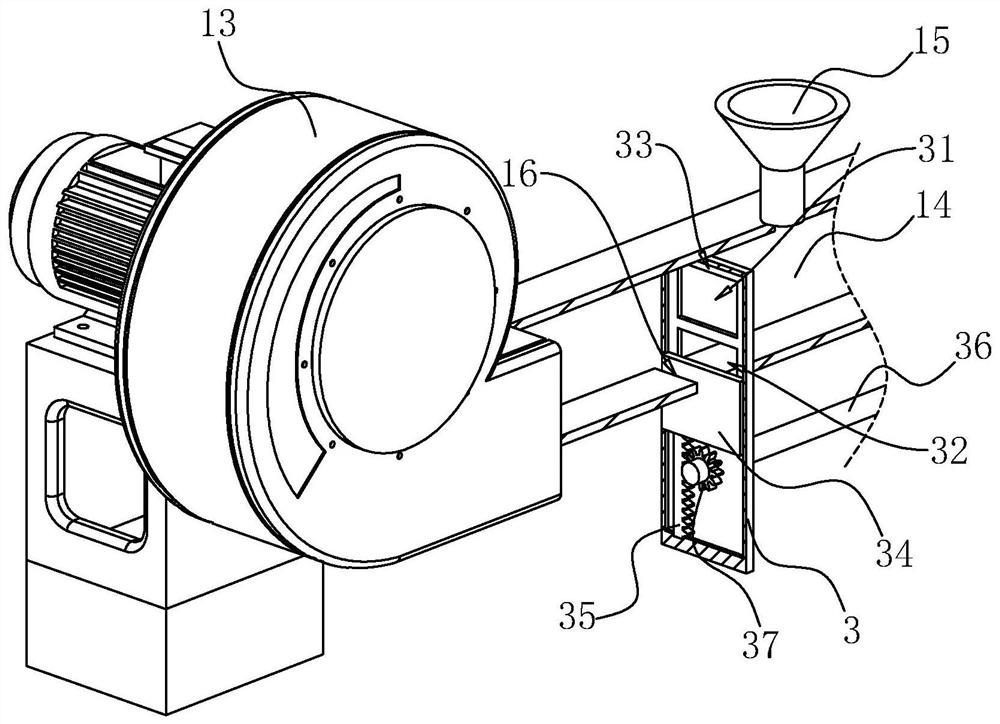

[0035] The following is attached Figure 1-7 The application is described in further detail.

[0036] The embodiment of the present application discloses a concrete powder storage device. refer to figure 1 and figure 2 A concrete powder storage device includes a powder tank 1, a feed pipe 11 fixed on the outer peripheral surface of the powder tank 1, and a collection box 2 fixed on the bottom end of the feed pipe 11. A partition 12 is fixed on the inner peripheral surface of the powder tank 1, and the partition 12 divides the space in the powder tank 1 into an upper feeding area and a lower equipment area. An exhaust pump 13 is arranged around the powder tank 1, and an air outlet pipe 14 is fixed at the air outlet end of the exhaust pump 13, and the air outlet pipe 14 runs through the side wall of the powder tank 1 and is arranged in the equipment area below the partition 12. A plurality of exhaust pipes 15 are evenly distributed on the top surface of the air outlet pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com