Lightweight composite automobile body plate for automobile impact buffering and energy absorption

An impact buffering and lightweight technology, applied in vehicle components, superstructure, transportation and packaging, etc., can solve the problems of low impact buffering energy absorption efficiency, complicated preparation process, endangering the life and health of occupants, etc., and achieve high plastic deformation energy absorption. , make up for the effect of excessive deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

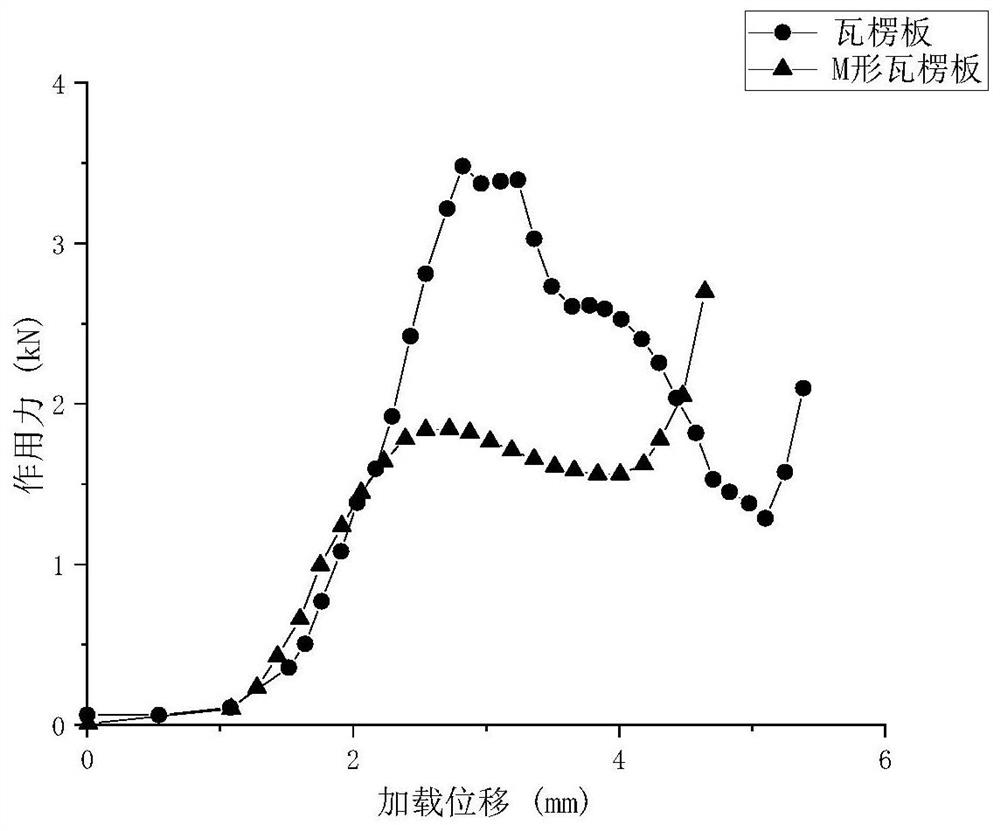

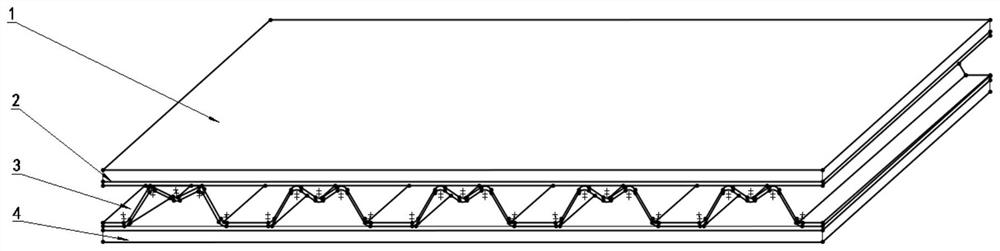

Embodiment 1

[0033] like figure 2 As shown, this embodiment is a lightweight composite body panel for automobile impact buffering and energy absorption. The lightweight composite automobile panel includes layered fiber reinforced composite materials on both sides and a corrugated metal member in the center. The fiber-reinforced composite materials are the top carbon fiber-reinforced composite material and the bottom carbon fiber-reinforced composite material, and the layered fiber-reinforced composite materials on both sides are connected to the central corrugated metal member through adhesives or fasteners. Among them, the aluminum alloy plate with a thickness of 0.5 mm is used to punch the central corrugated metal member, the shape of the unit unit of the central corrugated metal member is M-shaped, the overall thickness of the corrugated metal member is 4.1 mm, and the composition unit of the corrugated metal member is five The length of a single component unit of the corrugated metal ...

Embodiment 2

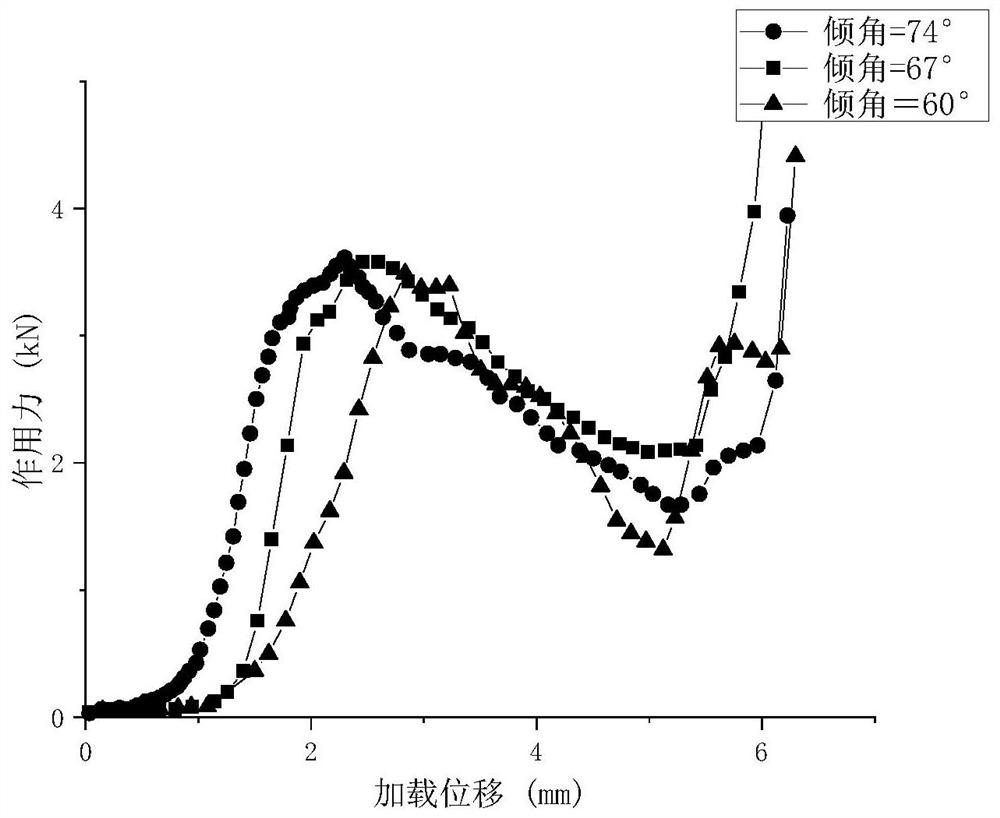

[0036] like Figure 4 As shown, this embodiment is a lightweight composite body panel for automobile impact buffering and energy absorption. The lightweight composite automobile panel includes layered fiber reinforced composite materials on both sides and a corrugated metal member in the center. The fiber-reinforced composite materials are the top carbon fiber-reinforced composite material and the bottom carbon fiber-reinforced composite material, and the layered fiber-reinforced composite materials on both sides are connected to the central corrugated metal member through adhesives or fasteners. Among them, the advanced high-strength steel plate with a thickness of 0.5 mm is used to stamp into the central corrugated metal member, the shape of the unit unit of the central corrugated metal member is selected as parabolic, and the composition unit of the corrugated metal member is five, and the corrugated metal member The length of a single component unit is 20mm, and the inclin...

Embodiment 3

[0039] like Figure 4 As shown, this embodiment is a lightweight composite body panel for automobile impact buffering and energy absorption. The lightweight composite automobile panel includes layered fiber reinforced composite materials on both sides and a corrugated metal member in the center. The fiber-reinforced composite materials are the top carbon fiber-reinforced composite material and the bottom carbon fiber-reinforced composite material, and the layered fiber-reinforced composite materials on both sides are connected to the central corrugated metal member through adhesives or fasteners. Among them, an advanced high-strength steel plate with a thickness of 0.8 mm is used to punch a central corrugated metal component, and the shape of the unit unit of the central corrugated metal component is selected as a parabola. The corrugated metal component consists of seven units, and the corrugated metal component The overall thickness of the unit is 4.5mm, the length of a sing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com