Structural color film with humidity response characteristic and preparation method of structural color film

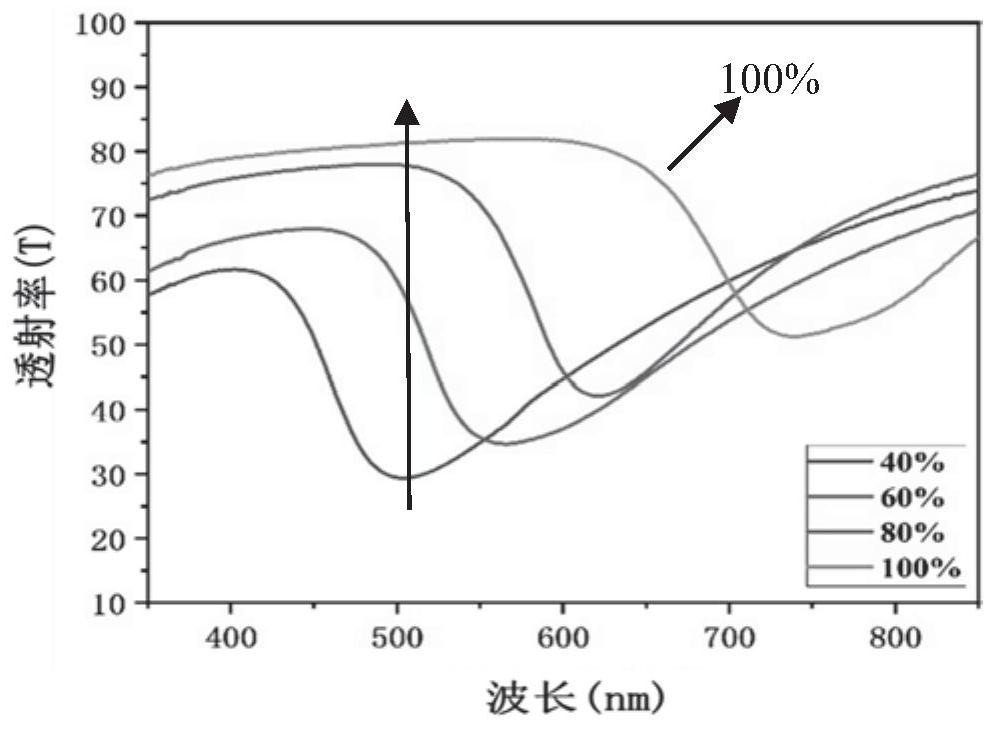

A technology of humidity response and structural color, which is applied in the direction of chemical instruments and methods, coatings, layered products, etc., can solve the problems of poor environmental response cycle effect and weak rapid response ability, and achieve good reversibility and reversibility. good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A method for preparing a liquid crystal film with humidity response characteristics, comprising the steps of:

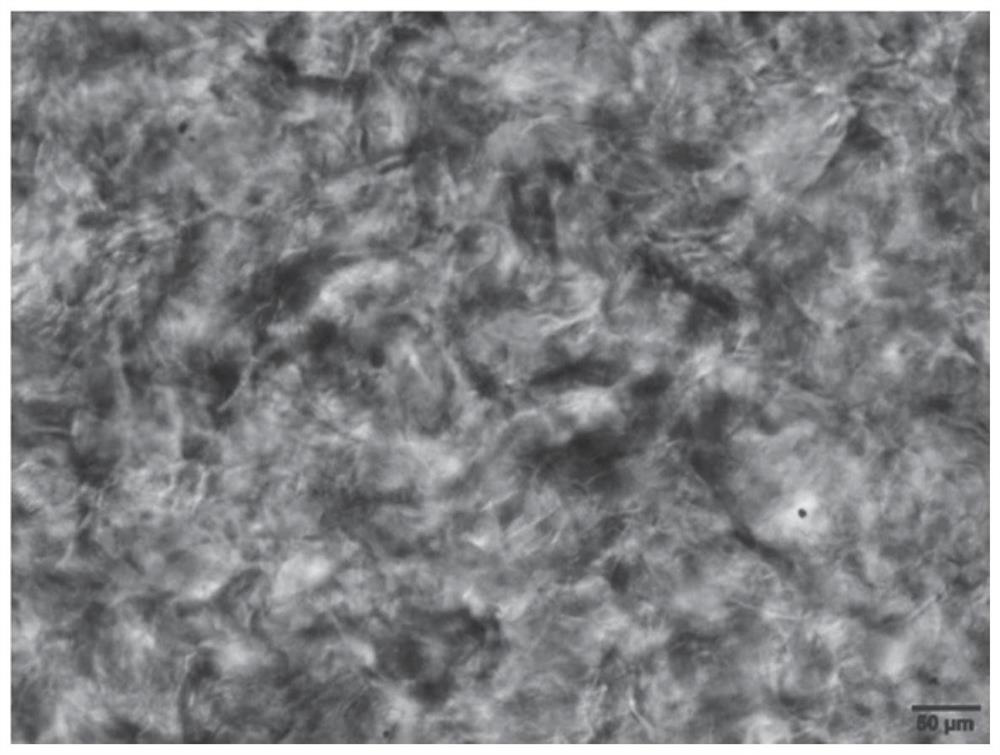

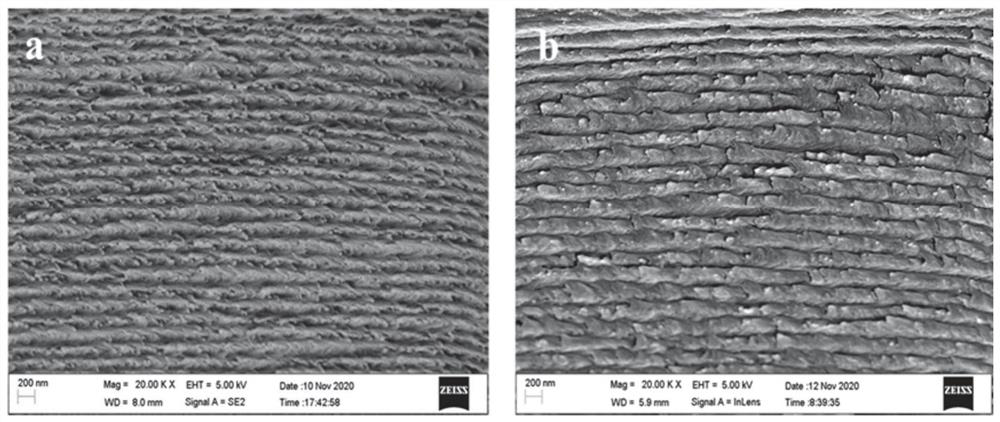

[0041] (1) Wood fibers (taking coniferous wood as an example) were hydrolyzed in 60wt% sulfuric acid for 60min (normal temperature hydrolysis). After the hydrolysis, deionized water with 10 times the sulfuric acid content was added to terminate the reaction. Centrifuge at a temperature of 10°C for 6 minutes to screen the cellulose nanocrystal suspension with a certain size; homogenize the obtained cellulose nanocrystal suspension through a D12 homogenizer for 10 times to obtain fibers with uniform size Suspension of prime nanocrystals; the size of cellulose nanocrystals is 350-600nm;

[0042] (2) Using water to prepare 1wt% and 20wt% glycerin solutions respectively, let stand for 12h, and set aside;

[0043] (3) The cellulose nanocrystal suspension in the step (1) is concentrated to 3wt% (the solvent in the suspension is water) by rotary evaporation, and the ...

Embodiment 2

[0051] A method for preparing a liquid crystal film with humidity response characteristics, comprising the steps of:

[0052] (1) Wood fibers (taking coniferous wood as an example) were hydrolyzed in 65wt% sulfuric acid for 60 minutes. After the hydrolysis, deionized water with 10 times the sulfuric acid content was added to terminate the reaction. Centrifuge for 6 minutes under the state of sieve to screen out the cellulose nanocrystal suspension with a certain size, and homogenize the obtained cellulose nanocrystal suspension through a D12 homogenizer for 12 times to obtain cellulose nanocrystals with uniform size; The size of cellulose nanocrystals is 300-550nm;

[0053] (2) Using water to prepare 2wt% and 25wt% glycerin solutions respectively, let stand overnight, and set aside;

[0054] (3) The cellulose nanocrystal suspension in step (1) is concentrated to 3wt% by rotary evaporation, and the glycerol solution of 2wt% in step (2) is at room temperature according to the m...

Embodiment 3

[0058] A method for preparing a liquid crystal film with humidity response characteristics, comprising the steps of:

[0059] (1) Wood fibers (taking coniferous wood as an example) were hydrolyzed in 62wt% sulfuric acid for 70 minutes. After the hydrolysis, deionized water with 10 times the sulfuric acid content was added to terminate the reaction. Centrifuge for 6 minutes under the state of sieve to screen out the suspension of cellulose nanocrystals with a certain size. Homogenize the obtained cellulose nanocrystal suspension through a homogenizer with a specification of D12 for 15 times to obtain cellulose nanocrystals with uniform size; the size of the cellulose nanocrystals is 260-500nm;

[0060] (2) Using water to prepare 3wt% and 22wt% glycerin solutions respectively, leave it to stand overnight, and stand-by;

[0061] (3) The cellulose nanocrystal suspension in step (1) is concentrated to 3wt% by rotary evaporation, and the glycerol solution of 3wt% in step (2) is at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com