Cooling unit for plastic support mold

A technology for cooling units and plastic brackets, applied in springs/shock absorbers, vibration suppression adjustments, mechanical equipment, etc., can solve problems such as low product quality, reduced production efficiency, and rapid cooling, so as to improve production efficiency and quality, reduce Effect of vibration and stable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

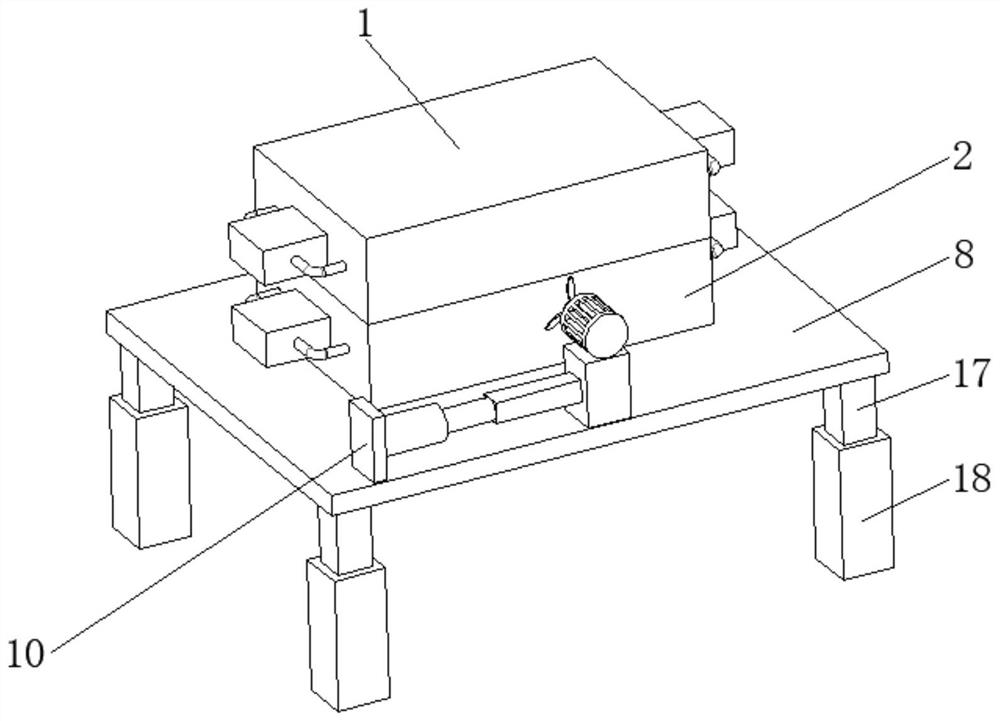

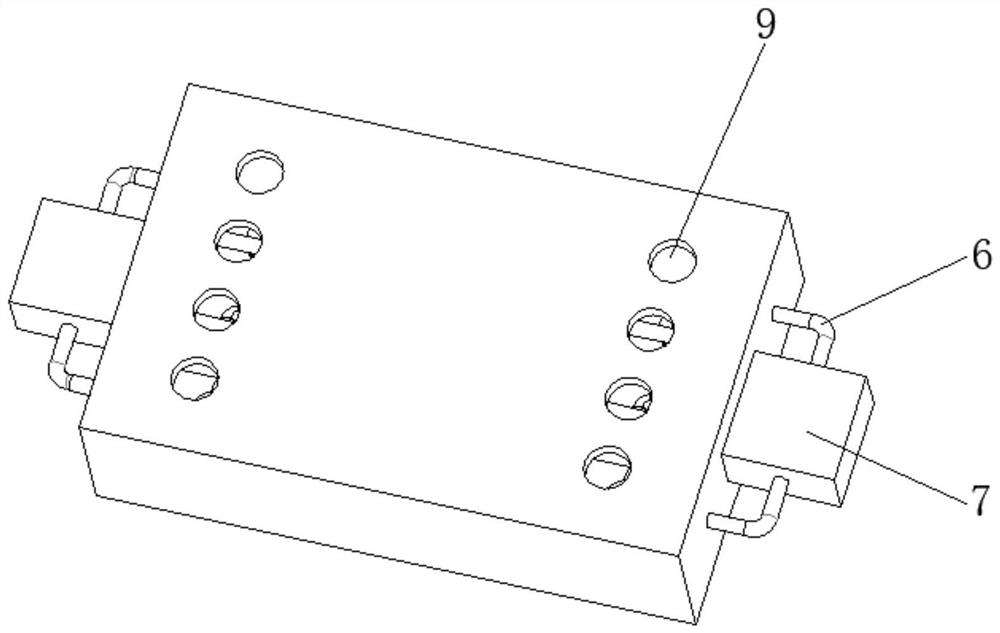

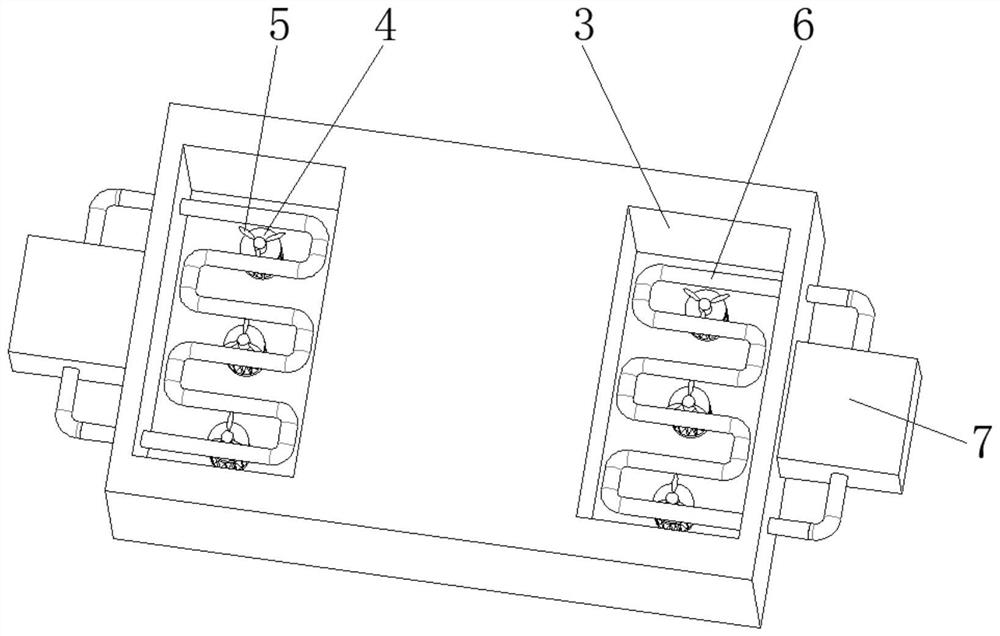

[0024] Such as Figure 1-4 As shown, the present invention provides a cooling unit for a plastic bracket mold, comprising an upper mold 1 and a lower mold 2, both sides of the upper mold 1 and the lower mold 2 are provided with a cavity 3, and the first fan is fixedly installed in the cavity 3 and the condensation pipe 6, the condensation pipe 6 is distributed in the cavity 3 in an S shape, the first fan includes the first motor 4 and the first fan blade 5, and a plurality of first motors 4 are fixedly installed on the bottom surface of the inner wall of the cavity 3, which is the first fan The blades 5 rotate to provide power, the output shaft of the first motor 4 is fixedly installed with a number of first fan blades 5, the cooling pumps 7 are fixedly installed on both sides of the outer surface of the upper mold 1 and the lower mold 2, and the condensation pipe 6 passes through the upper mold 1 and the lower mold 2. The mold 2 is connected with a cooling pump 7, the water o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com