Prefabricated concrete member steam curing plant building method based on solar energy utilization

A prefabricated concrete and steam curing technology, used in manufacturing tools, auxiliary molding equipment, ceramic molding machines, etc., can solve the problems of low solar energy utilization, affecting light transmittance, dust falling on the roof, etc. The effect of high light utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

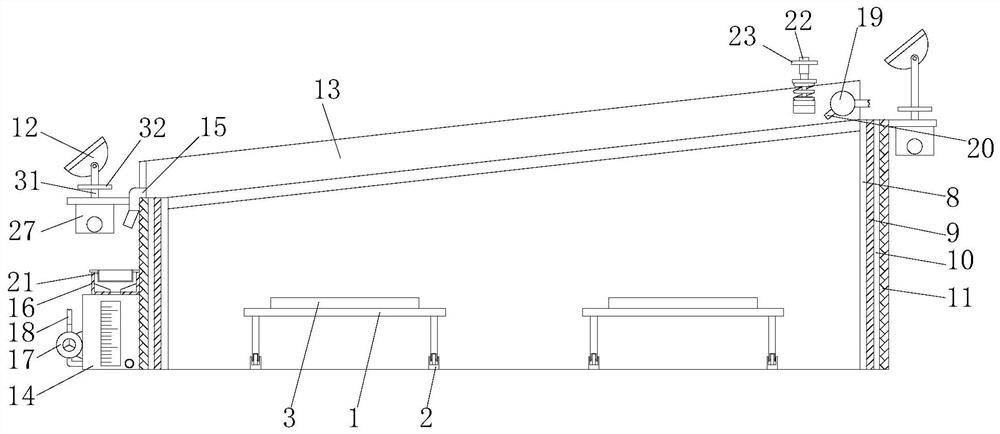

[0047] A method for constructing a prefabricated concrete element steam curing factory building based on solar energy utilization, comprising the following steps:

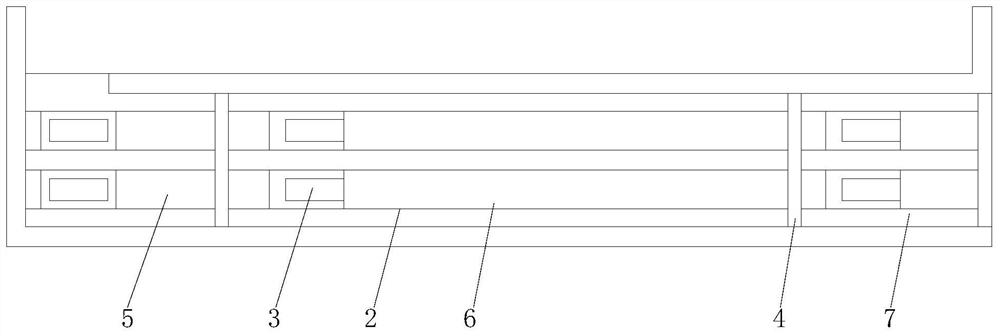

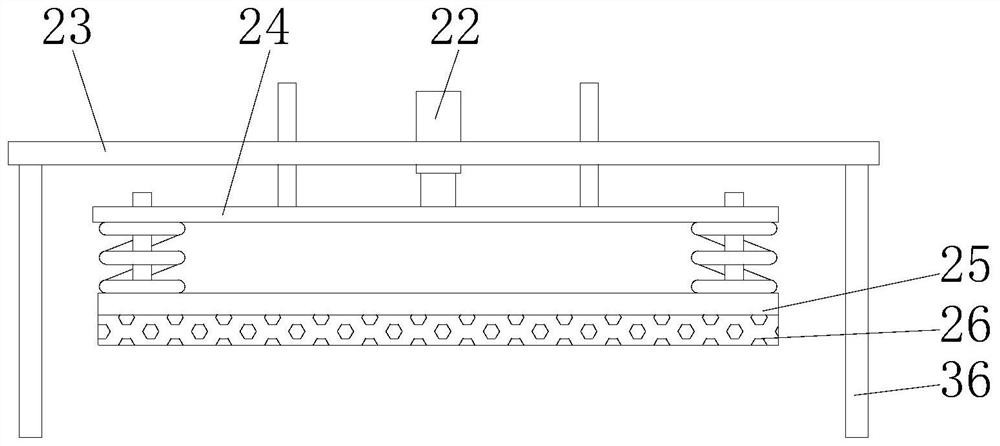

[0048] A: Rolling shutter doors 4 are installed inside the factory building, and the inside of the factory building is divided into a heating maintenance workshop 5, a constant temperature maintenance workshop 6 and a cooling maintenance workshop 7. The mold table track 2, the mold table 1 and the PC component 3 are respectively installed inside the factory building;

[0049] B: The static parking area is arranged on the north side, and the south side is arranged according to the heating, constant temperature, and cooling maintenance processes from west to east. The heating maintenance workshop and constant temperature maintenance workshop adopt light-transmitting roofs, and the cooling maintenance workshop adopts concrete roofs;

[0050] C: Heating, constant temperature, and cooling maintenance are collectively ref...

Embodiment 2

[0062] A method for constructing a prefabricated concrete element steam curing factory building based on solar energy utilization, comprising the following steps:

[0063] A: Rolling shutter doors 4 are installed inside the factory building, and the inside of the factory building is divided into a heating maintenance workshop 5, a constant temperature maintenance workshop 6 and a cooling maintenance workshop 7. The mold table track 2, the mold table 1 and the PC component 3 are respectively installed inside the factory building;

[0064] B: The static parking area is arranged on the north side, and the south side is arranged according to the heating, constant temperature, and cooling maintenance processes from west to east. The heating maintenance workshop and constant temperature maintenance workshop adopt light-transmitting roofs, and the cooling maintenance workshop adopts concrete roofs;

[0065] C: Heating, constant temperature, and cooling maintenance are collectively ref...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com