Rapid dynamic response synchronous phase modifier stepped external cold water temperature control method

A temperature control method and dynamic response technology, applied in temperature control, non-electric variable control, control/regulation system, etc., can solve the problems of unfavorable fan polling backup management, unfavorable equipment stable operation, and inconvenience of normal maintenance, etc., to achieve linearity Good accuracy, suppression of occasional interference, and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is described in further detail now in conjunction with accompanying drawing.

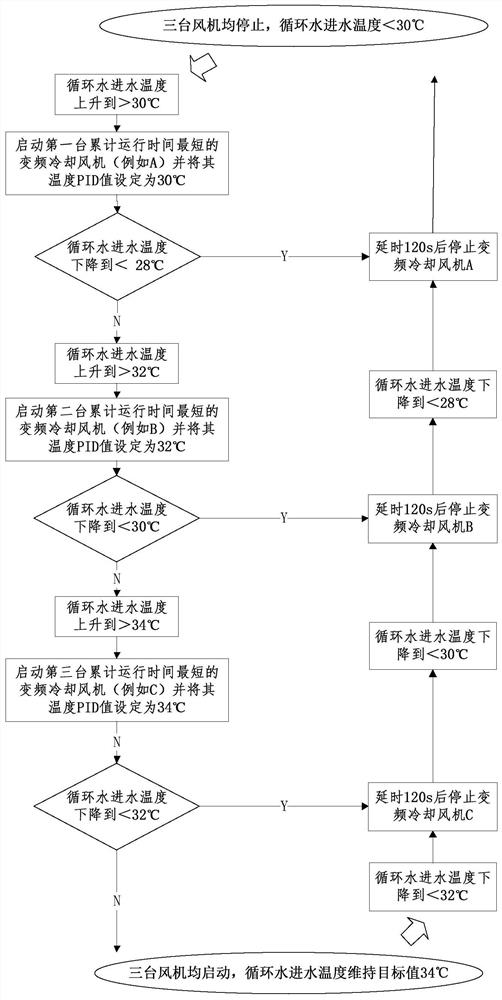

[0020] For the external cooling water cooling system of the condenser equipped with 3 cooling towers and each cooling tower is equipped with a frequency conversion cooling fan, the present invention provides a step-type external cooling water temperature control method for fast dynamic response synchronous condensers. Depend on figure 1 As can be seen, the concrete control flow of the present invention is:

[0021] (1) When the temperature of the external cooling water is greater than 30°C, start the first variable frequency cooling fan A with the shortest cumulative running time, the starting frequency is 30Hz, and set the temperature PID value of the variable frequency cooling fan A to 30°C, the variable frequency cooling fan A A Automatically adjust the operating frequency according to the set value of the temperature PID and the real-time external cooling water temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com