A kind of servo motor testing system and method thereof

A servo motor and testing system technology, applied in the field of servo motors, can solve the problems of high cost, tediousness, and lack of intelligence, achieve high flexibility, solve the problem of response speed, and protect the effect of safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

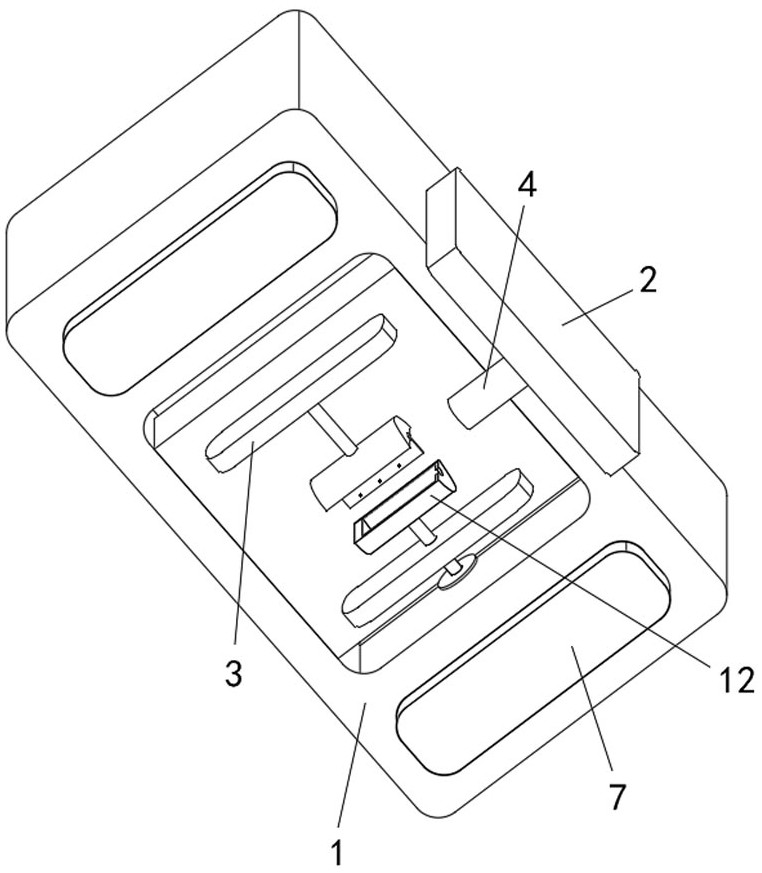

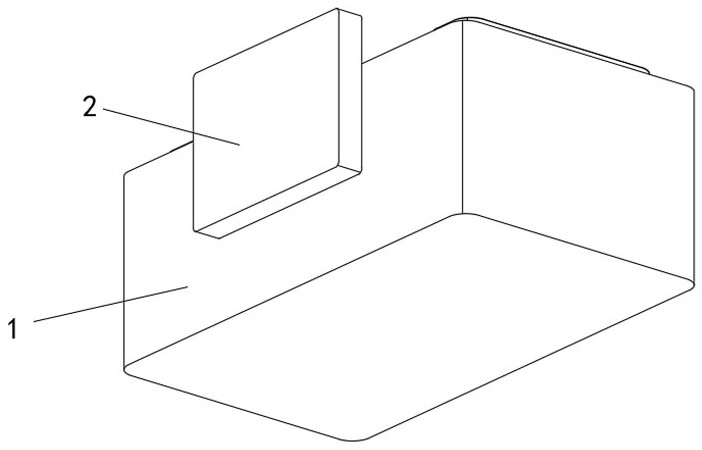

[0037] Such as Figure 1-3 As shown, a servo motor testing system includes an operating table 1 and an auxiliary housing 2. The auxiliary housing 2 is used to install components that do not belong to the operating table 1. It is a square metal housing as a whole and is divided into two spaces. The upper space is for It is used to install sensors and other components, while the lower space is used to accommodate mechanical components. The purpose of separation is to separate vibration and component operation activities from each other, so as to achieve the purpose of stability and safety of sensors. The auxiliary shell 2 is fixed on one side of the console 1. And the top of the accessory shell exceeds the top surface of the console 1, and the protruding part is for the installation of the sensor, and is also convenient for the original port to be exposed.

[0038] Such as Figure 5 As shown, the upper end surface of the console 1 has a first pit and a plurality of second pits,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com