Slag removal device of chemical production boiler

A technology for chemicals and boilers, which is applied in the field of slag removal devices for chemical production boilers. It can solve the problems of affecting the health of operators, dust spreading, and slag easily remaining on scrapers, etc., so as to prevent dust spreading and prolong the sealing time. , reduce the effect of dust diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

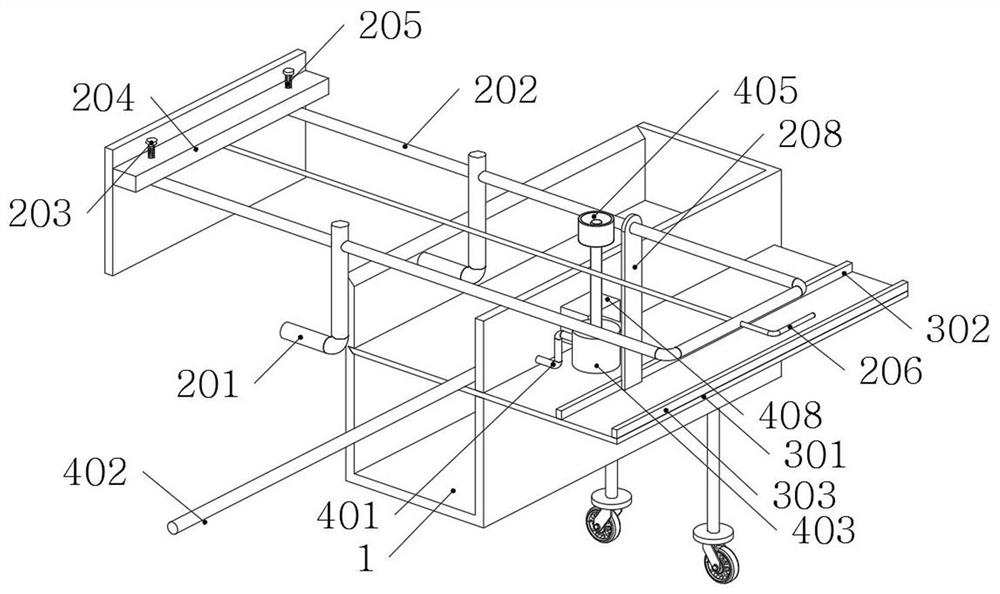

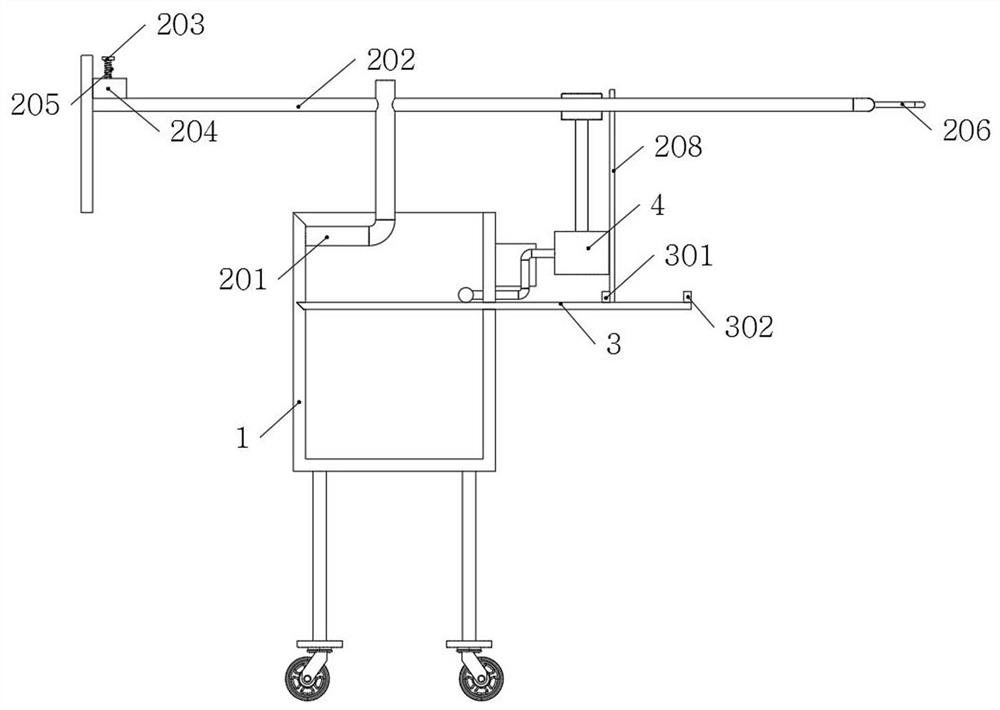

[0038] as attached figure 1 To attach Figure 9 Shown:

[0039]The invention provides a slag cleaning device for a chemical production boiler, comprising a collection box 1, a cleaning part 2 and a dust suction part 4; the collection box 1 is placed on the ground; the cleaning part 2 consists of a sliding seat 201, a sliding arm 202, a sliding rod 203, a scraper 204, an elastic member 205, an auxiliary lever 206, a toggle lever 207 and a toggle plate 208, and two sliding seats 201 are provided, and the two sliding seats 201 are installed on the collection box 1 by bolts; A baffle 3 is plugged into the collection box 1; the suction part 4 is composed of an air intake pipe 401, an air intake head 402, a fan 403, a ratchet gear 404, a casing 405, a toggle tooth 406, an exhaust pipe 407 and a filter box 408 , and the air inlet pipe 401 is installed on the collection box 1; the air inlet pipe 401 is connected with an air inlet head 402, and the air inlet head 402 is located in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com