Application method of water injection well whole shaft tubular column dissolved oxygen corrosion simulation device

A technology of corrosion device and application method, applied in isolation devices, wellbore/well components, chemical instruments and methods, etc., can solve problems such as difficulty in simulating dissolved oxygen corrosion behavior, and achieve reduced experimental cost, good repeatability, and reduced experimental effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

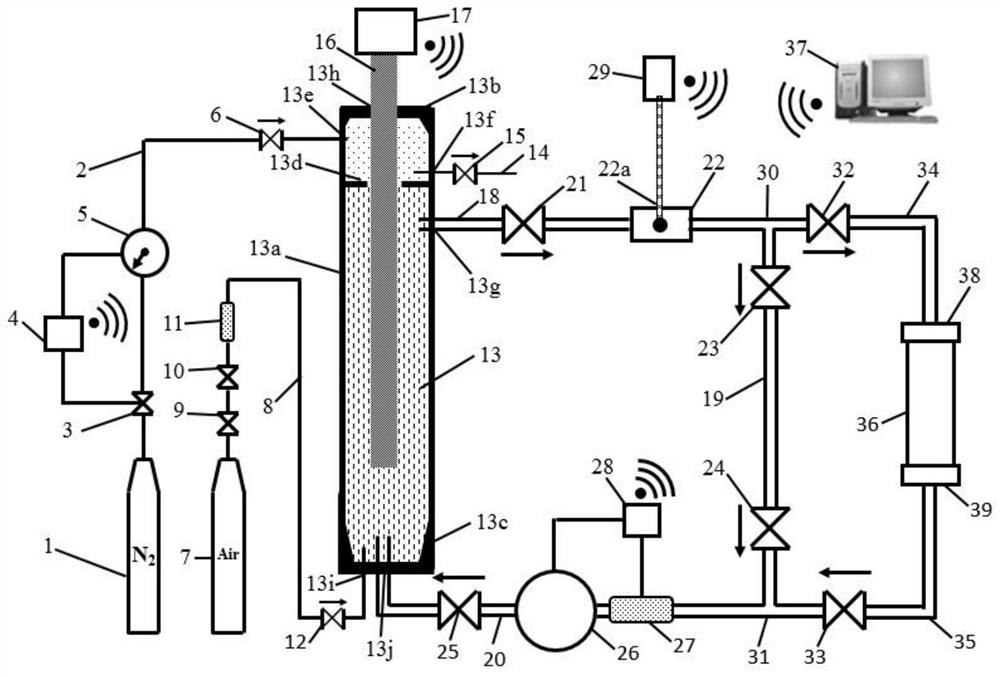

[0050] A method for evaluating the dissolved oxygen corrosion of the whole wellbore string of a simulated water injection well, comprising the following steps:

[0051] Step 1: According to the pressure p(h) and temperature T(h) of the downhole water injection string at any well depth h, the pressure-time data p(t) of the test nitrogen pressure reducing valve controller 4 is converted by formula (1) And the temperature-time data T(t) of the electric heating controller 17.

[0052]

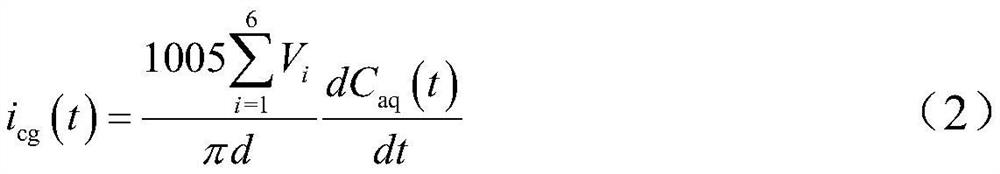

[0053] In the formula: t is the experiment time, min; Q is the daily discharge of injected water, m 3 / d; h is any well depth, m; d is the inner diameter of water injection string, mm; V 1 is the volume of the pipe section below the annular partition 13d of the liquid storage riser, L; V 2 is the volume of corrosion test pipe section 36, L; V 3 is the volume of the upper horizontal pipe 18, L; V 4 is the volume of the lower horizontal pipe 20, L; V 5 is the volume of the upper L-shaped pipe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com