Stone-plastic profile and preparation method thereof

A stone-plastic and profile technology, applied in the field of stone-plastic profiles and their preparation, can solve the problems of difficult recycling of waste residues, complex process, secondary pollution, etc., and achieve the goals of widening the scope of recycling, simple preparation methods, and ensuring uniformity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

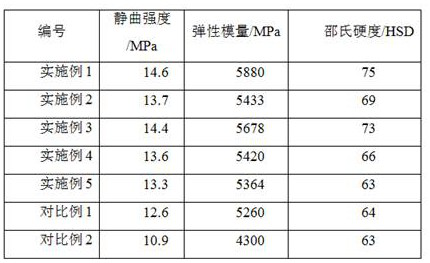

Examples

Embodiment 1

[0026] S1 Pretreatment of returned materials: the collected returned materials are crushed and screened for later use;

[0027] S2 Pretreatment of dicyandiamide waste residue: air-dry or heat-dry dicyandiamide waste residue until the water content is 5%~6%, and then sieve to obtain dicyandiamide waste residue powder with a particle size of 2000~3000 mesh;

[0028] S3 Removal of impurities: removing the dicyandiamide waste slag powder obtained in step S2 at a temperature of 350° C. in an oxygen-containing air flow, and the impurities include carbon black and nitrogen-containing compounds;

[0029] S4 Mixing of raw materials: Add polyvinyl chloride, recycled materials, dicyandiamide waste residue, acrylic resin, stabilizer, chlorinated polyethylene, polypropylene wax and stearic acid into the heat mixing tank in proportion to stir, and raise the temperature to As high as 110°C, then transfer the raw materials to the cold mixing tank to continue stirring, and stop stirring when t...

Embodiment 2

[0034] S1 Pretreatment of returned materials: the collected returned materials are crushed and screened for later use;

[0035] S2 Pretreatment of dicyandiamide waste residue: air-dry or heat-dry the dicyandiamide waste residue until the water content is 8%~10%, and then sieve to obtain dicyandiamide waste residue powder with a particle size of 2000~3000 mesh;

[0036] S3 Removal of impurities: removing the dicyandiamide waste slag powder obtained in step S2 at a temperature of 450° C. in an oxygen-containing air flow, and the impurities include carbon black and nitrogen-containing compounds;

[0037] S4 Mixing of raw materials: Add polyvinyl chloride, recycled materials, dicyandiamide waste residue, acrylic resin, stabilizer, chlorinated polyethylene, polypropylene wax and stearic acid into the heat mixing tank in proportion to stir, and raise the temperature to As high as 130°C, then transfer the raw materials to the cold mixing tank to continue stirring, and stop stirring w...

Embodiment 3

[0042] S1 Pretreatment of returned materials: the collected returned materials are crushed and screened for later use;

[0043] S2 Pretreatment of dicyandiamide waste residue: air-dry or heat-dry the dicyandiamide waste residue until the water content is 9%~10%, and then sieve to obtain dicyandiamide waste residue powder with a particle size of 2000~3000 mesh;

[0044] S3 Removal of impurities: removing the dicyandiamide waste slag powder obtained in step S2 at a temperature of 600° C. in an oxygen-containing air flow, and the impurities include carbon black and nitrogen-containing compounds;

[0045] S4 Mixing of raw materials: Add polyvinyl chloride, recycled materials, dicyandiamide waste residue, acrylic resin, stabilizer, chlorinated polyethylene, polypropylene wax and stearic acid into the heat mixing tank in proportion to stir, and raise the temperature to As high as 135°C, then transfer the raw materials to the cold mixing tank to continue stirring, and stop stirring w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com