Oil-seepage-proof concrete and special construction device thereof

A construction device and concrete technology, applied in the field of concrete, can solve the problems of unsatisfactory oil seepage prevention effect, reduce the gripping force of steel bars, etc., and achieve the effects of being beneficial to surface smoothing, improving strength, and eliminating honeycomb hemp surface.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

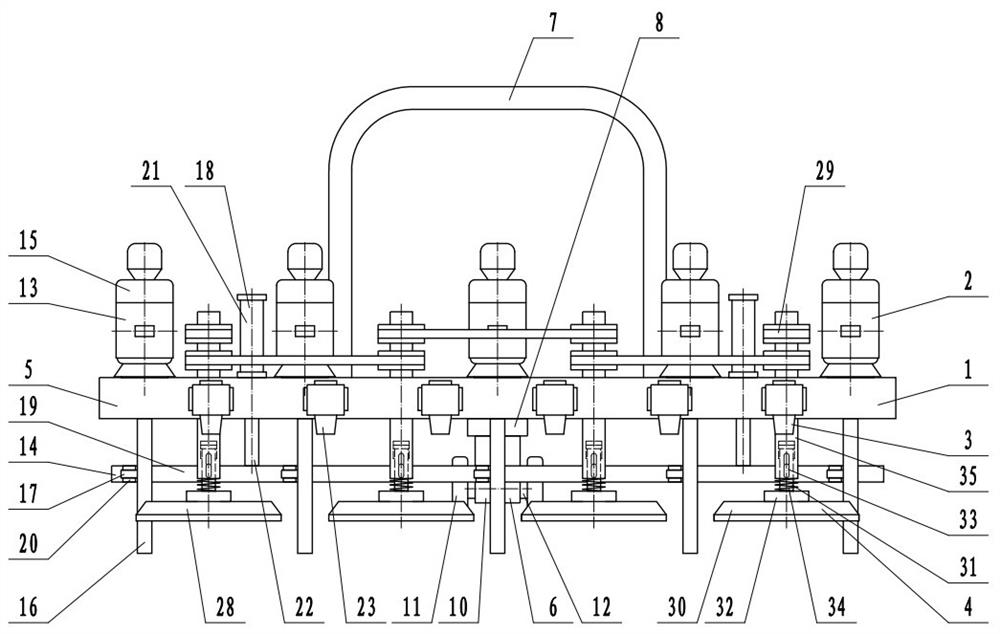

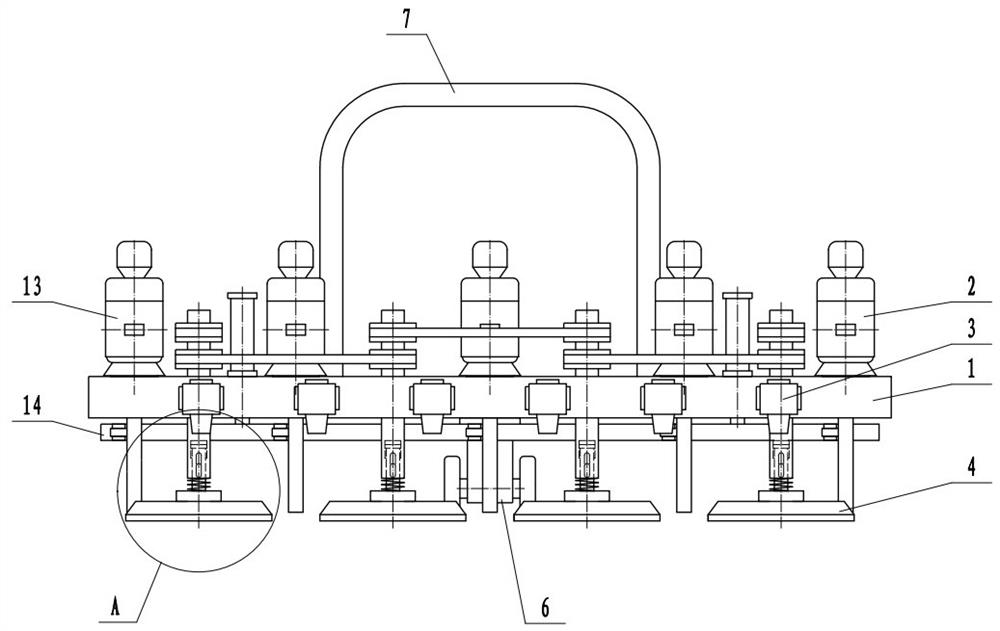

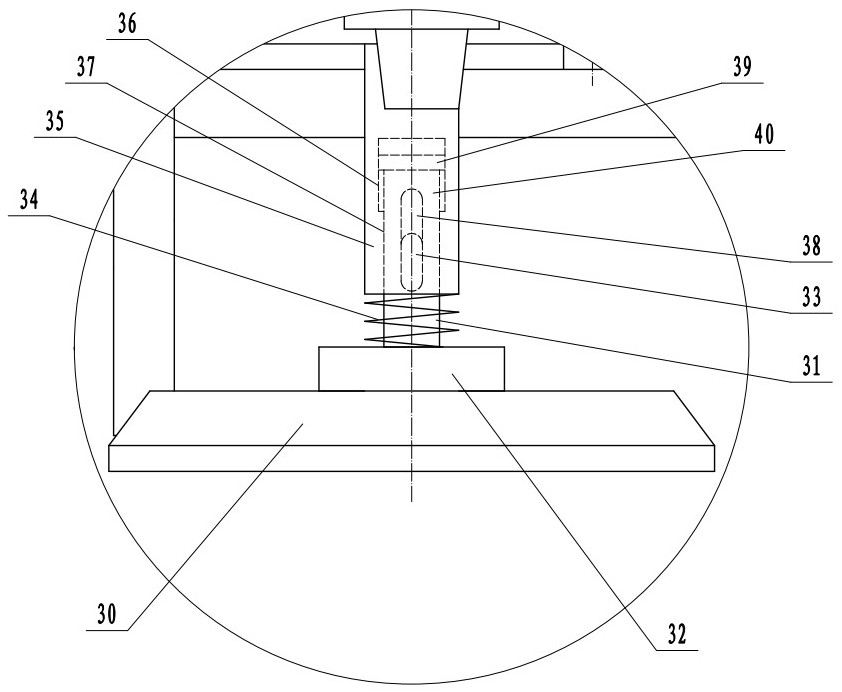

[0045] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

[0046] An oil-seepage-proof concrete, which includes an oil-seepage-proof concrete base material and an oil-seepage-proof concrete base surface slurry, and the oil-seepage prevention concrete base material and the oil-seepage concrete base surface slurry are jointly used by a special construction device, and the anti-oil seepage concrete base surface slurry The oil-permeable concrete base surface slurry is laid on the surface of the oil-permeable concrete substrate.

[0047] The anti-oil seepage concrete substrate includes the following components in parts by weight:

[0048] 260 parts of cement,

[0049] 665 parts of river sand,

[0050] 450 parts of fine aggregate,

[0051] 2 parts of water reducing agent,

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com