Forced linkage type hybrid power motorcycle

A hybrid and motorcycle technology, applied in the field of forced linkage hybrid motorcycles, can solve problems such as power loss, troublesome disassembly, waste of electric energy, etc., achieve strong load capacity, facilitate installation and maintenance, and ensure the effect of power transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

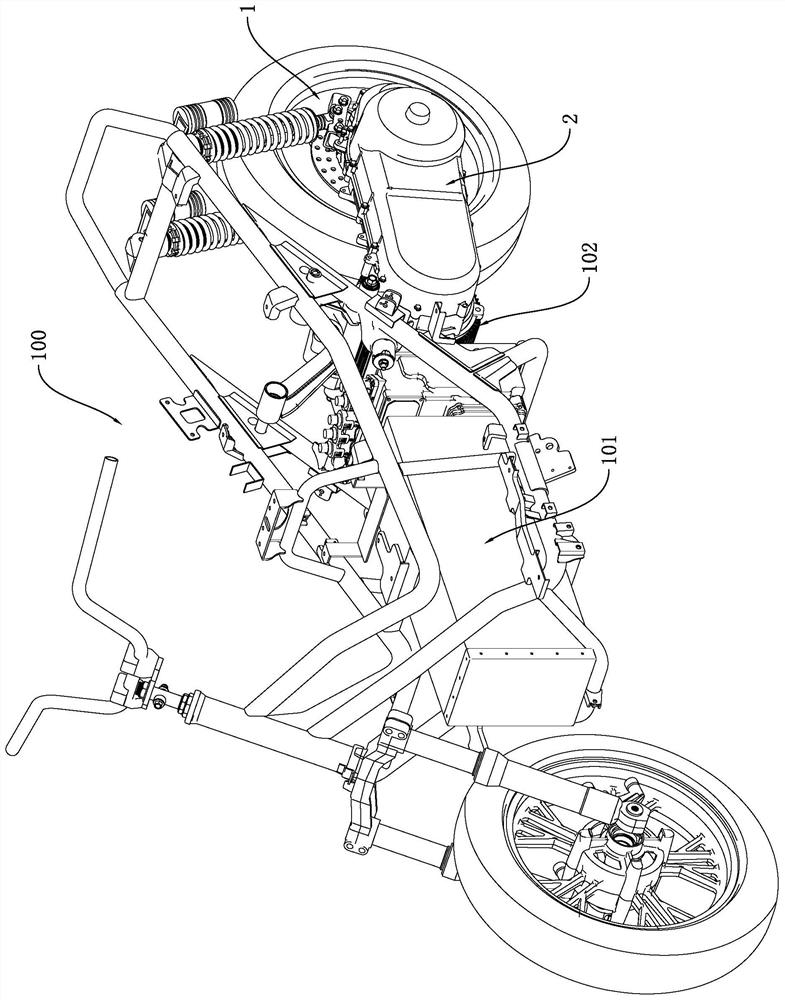

[0053] The forced linkage hybrid motorcycle includes a motorcycle main body 100, a gasoline power system 102 and a battery 101 are arranged in the middle of the motorcycle main body 100, and the rear part of the motorcycle main body 100 includes: the gasoline power system and the existing motorcycle The structure of the internal combustion engine is basically the same;

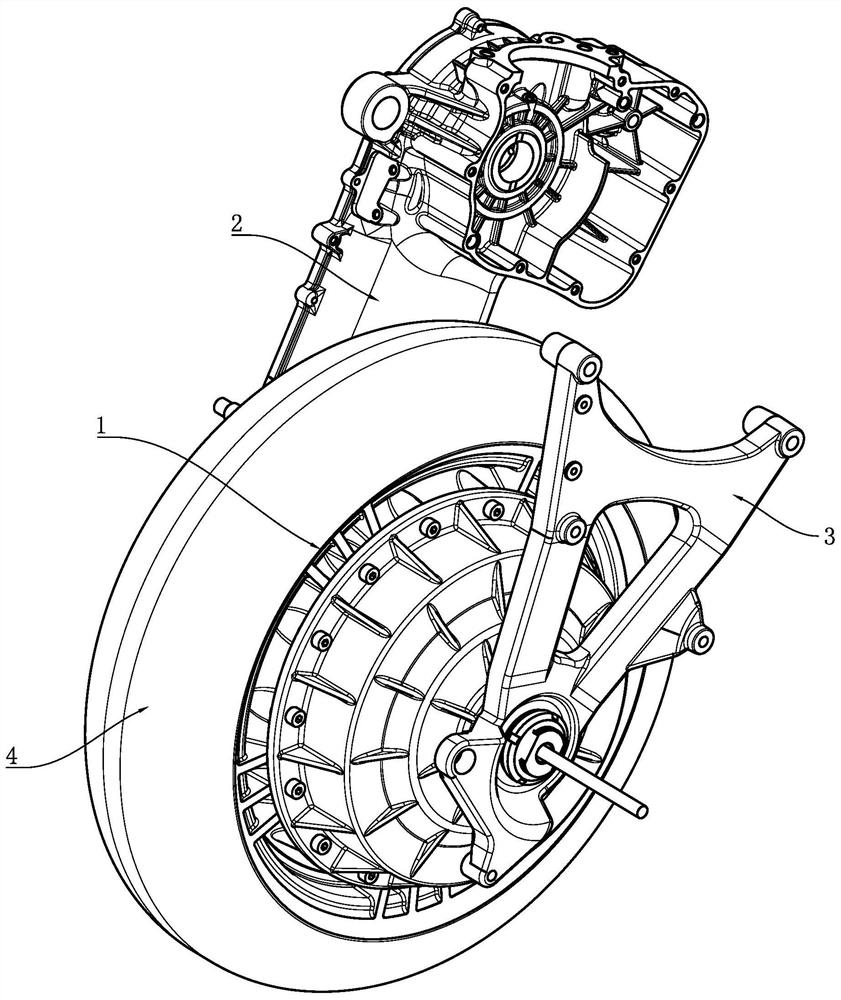

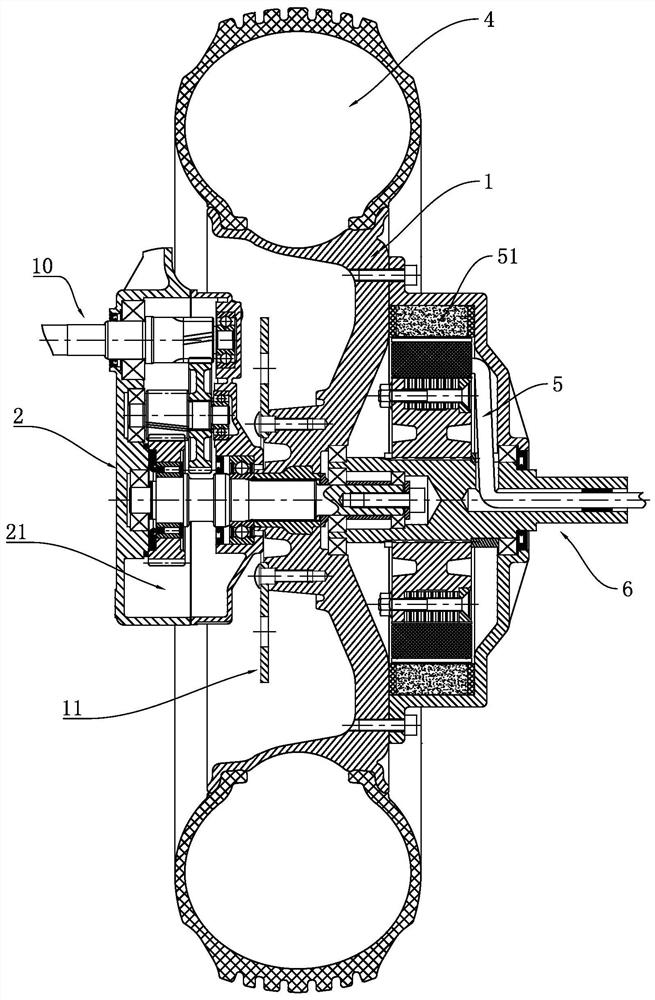

[0054] Gear box 2, the box body forms the left flat fork; the box body and the right side flat fork 3 cooperate to install the rear hub 1;

[0055] The input gear 31 is arranged in the reduction box 2 and is connected with the gasoline power system; the middle part of the input gear 31 is provided with an output shaft 61;

[0056]The fixed shaft 62 is fixed on the right flat fork 3; the output shaft 61 and the fixed shaft 62 are spliced along the same axis and can rotate relatively, and the output shaft 61 and the fixed shaft 62 are spliced to form the coupling 6; the design of the coupling 6 The gap betw...

Embodiment 2

[0078] Embodiment 2, this embodiment is basically the same as Embodiment 1, and its difference is as Figure 9 As shown, the high temperature locking mechanism 81 is a memory spring 880 , the memory spring 880 abuts on a push rod 881 , and the push rod 881 drives the roller 7 .

[0079] Generally, even in high temperature environment in summer, when the gasoline power system is not working, the internal temperature of the reducer will not exceed 60°C. Therefore, the trigger temperature of the high temperature locking mechanism 81 can be set between 60°C and 80°C.

[0080] When the gasoline power system is working, the temperature inside the reducer will gradually rise to about 80 degrees, and there will be no big difference between winter and summer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com