Regenerated plastic particle processing equipment

A technology of recycled plastic particles and processing equipment, which is applied in the field of plastic processing, can solve the problems of reducing work efficiency, affecting product quality, and easy to stick together, so as to prolong the service life, improve the sorting effect, and speed up the cooling rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

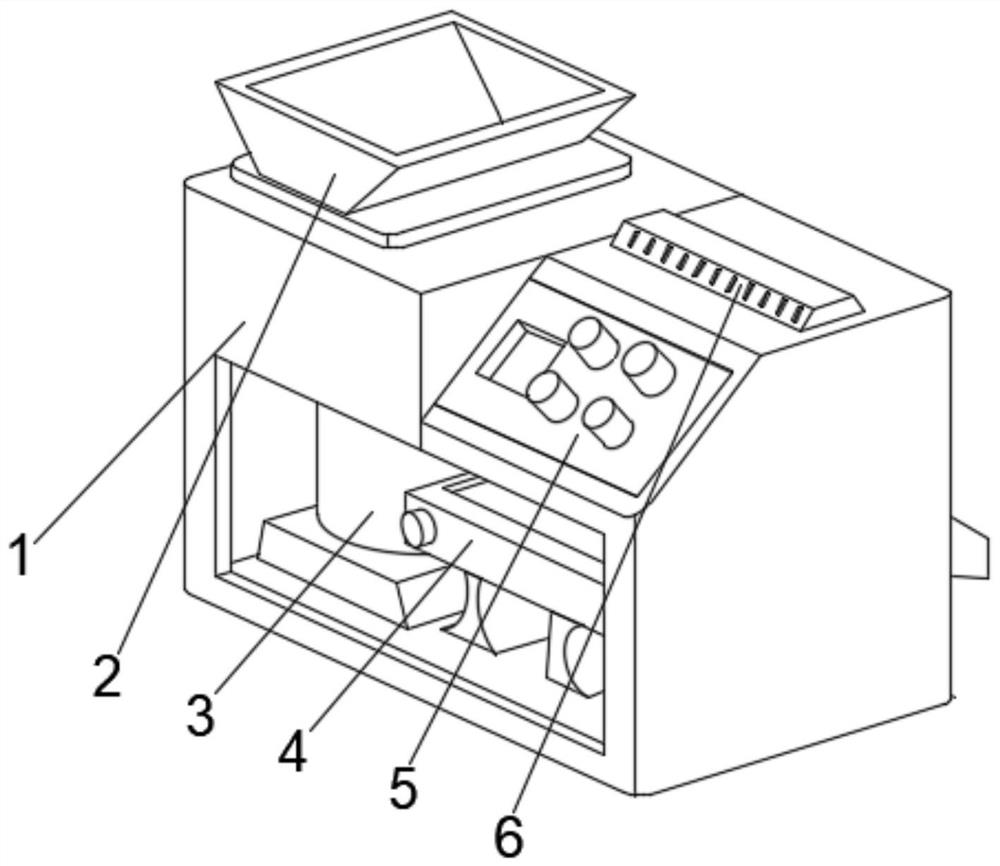

[0034] see Figure 1-2 , the present invention provides a technical solution: a recycled plastic particle processing equipment, including a main body 1, a feeding hopper 2 is arranged at the middle position on the left side of the top of the main body 1, the bottom of the feeding hopper 2 runs through the main body 1, and the top of the main body 1 The middle part of the right side is fixedly connected with a ventilation plate 6, the top right side of the front of the main body 1 is fixedly connected with a control panel 5, the left side of the inner cavity bottom of the main body 1 is fixedly connected with a processing device 3, and the inner cavity bottom of the main body 1 is located at the bottom of the processing device 3. The right side is fixedly connected with transmission frame 4.

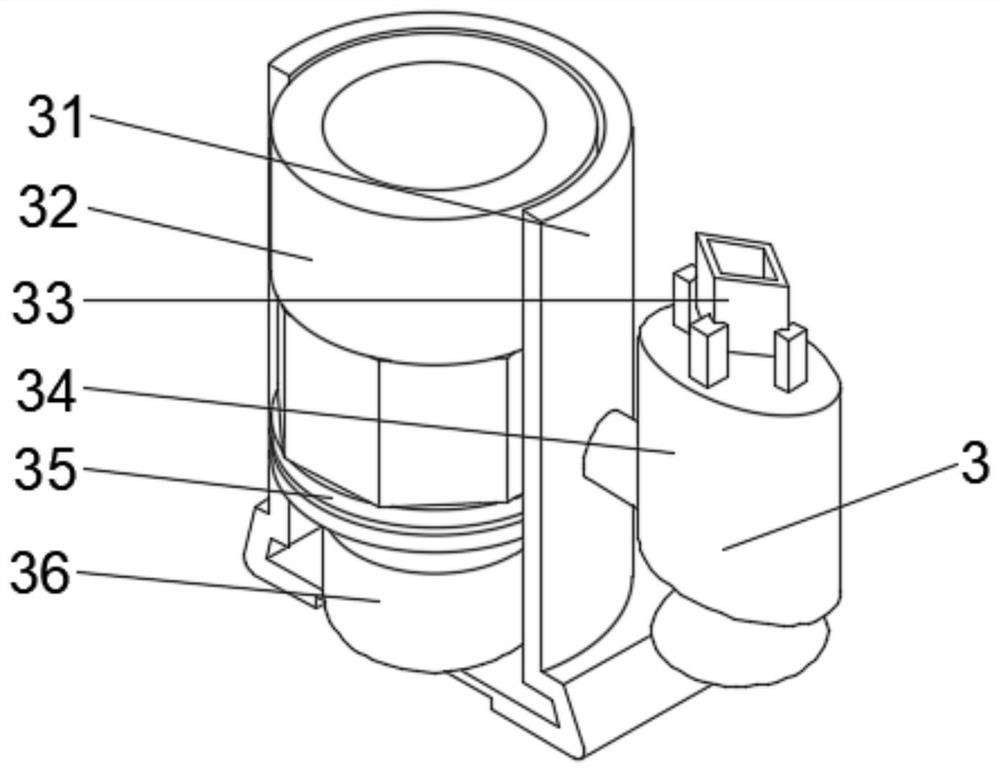

[0035] Wherein, the processing device 3 includes a fixed frame 31, a power box 36 is fixedly connected to the middle position of the inner cavity bottom of the fixed frame 31, and a partiti...

Embodiment 2

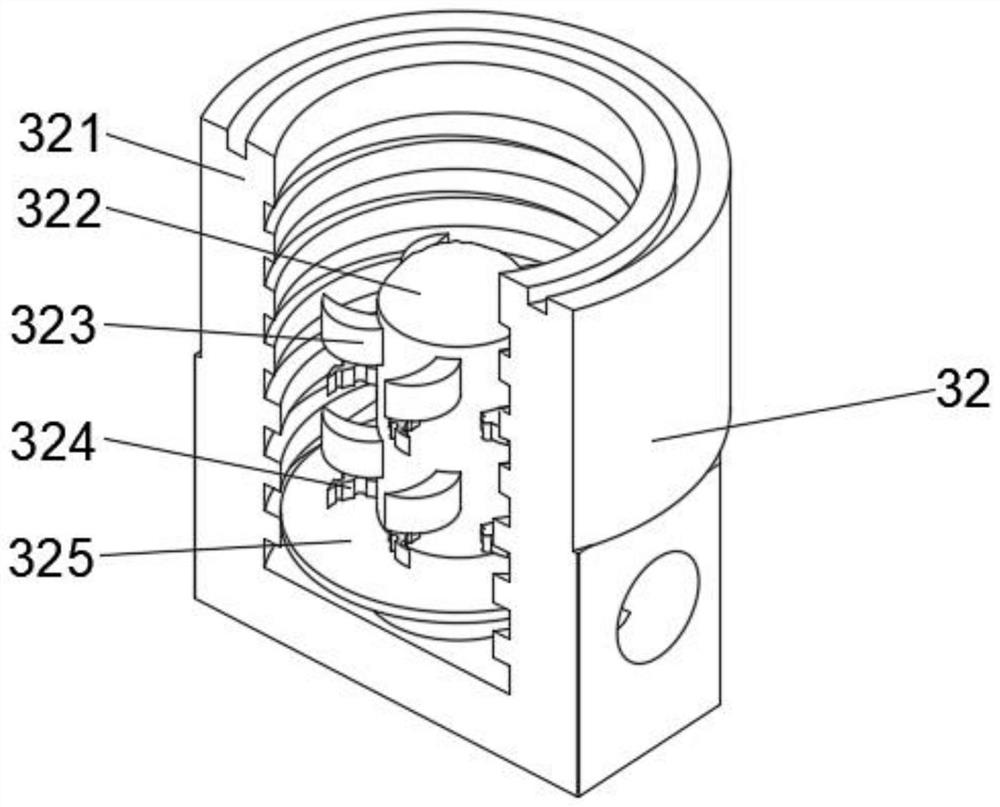

[0038] see Figure 1-4 , on the basis of Embodiment 1, the present invention provides a technical solution: component 1 of the processing mechanism 32 includes a protective shell 321, a rotating shaft 322 is provided at the middle of the bottom of the inner cavity of the protective shell 321, and the outer surface of the bottom end of the rotating shaft 322 is provided There is a flexible protective plate 325, the outer surface of the rotating shaft 322 is fixedly connected with an auxiliary knife 324 above the flexible protective plate 325, and the outer surface of the rotating shaft 322 is fixedly connected with a pelletizing knife 323 above the auxiliary knife 324.

[0039] Wherein, the component two of the auxiliary mechanism 34 comprises a stabilizing frame 341, the bottom middle position of the stabilizing frame 341 is provided with a lower hopper 345, the top of the lower hopper 345 runs through the stabilizing frame 341 and extends to the inside of the stabilizing frame...

Embodiment 3

[0042] see Figure 1-6 , on the basis of Embodiment 1 and Embodiment 2, the present invention provides a technical solution: component 2 of the processing mechanism 32 includes a bottom plate d1, a processing part d3 is fixedly connected to the middle of the top of the bottom plate d1, and the bottom plate The top of d1 is located on both sides of the workpiece d3 and is provided with a swing plate d2. The side of the swing plate d2 close to the workpiece d3 is fixedly connected with a contact plate d4, and the middle part of the contact plate away from the swing plate d2 is fixedly connected with an overhanging block d5. .

[0043] Wherein, the second component of the auxiliary mechanism 34 includes a mounting block t1, the top of the inner cavity of the mounting block t1 is fixedly connected with a lifting frame t2, the middle position of the bottom of the mounting block t1 is connected with a collecting pipe t5, and the top of the collecting pipe t5 runs through the mountin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com