A tin planting device for the production of lighting strip components

A technology of lighting lamps and components, applied in lighting devices, electric heating devices, auxiliary devices, etc., can solve the problems of continuous and stable operation, affecting the production efficiency of light strip components, difficult operation of tin planting light strips, etc., to ensure stability, The effect of improving the efficiency of tin planting and ensuring the stability of work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

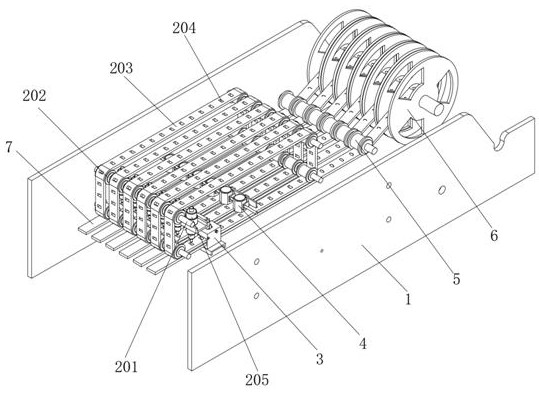

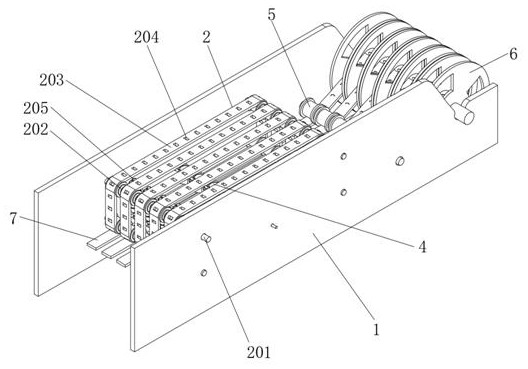

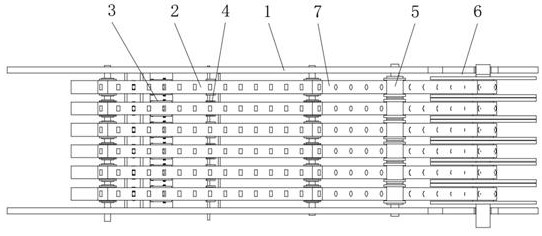

[0045] see Figure 1-6 , a tin planting device for the production of lighting strip components, including two side support plates 1 symmetrically arranged front and back, a tin planting assembly 2 is installed between the two side support plates 1, and the tin planting assembly 2 includes a rotating connection on the side Four sets of shaft rods 1 201 on the support plate 1, each shaft rod 1 201 is sleeved with a conveying roller 202 on the outer side, and the outer side of the four correspondingly arranged conveying rollers 202 is sleeved with a tin-planting ring belt 203, and the four corresponding The set conveying roller 202 is connected through the transmission of the tin-planting ring belt 203. The four shafts-201 are distributed between the two side support plates 1 in a rectangular shape. The bottom of the tin-planting ring belt 203 is horizontally set, and one of the shafts-201 A power drive device is connected externally.

[0046] The device is provided with four sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com