Plasma source chamber for a spectrometer

A technology of plasma source and spectrometer, applied in the direction of plasma, emission spectrum, instrument, etc., can solve the problems of needing pre-cooler, expensive, complex arrangement, etc., to avoid heat transfer, prevent air flow interference, and improve thermal insulation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

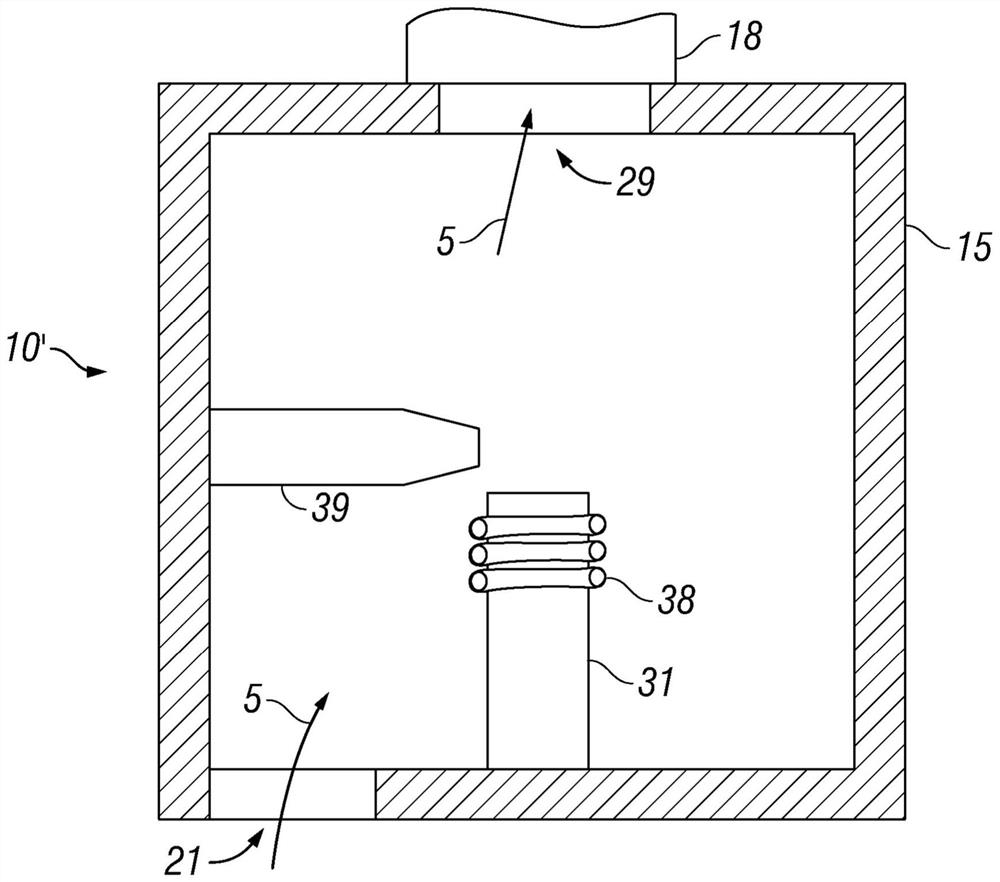

[0031] exist figure 1 A plasma chamber according to the prior art is schematically illustrated in cross-section in . Such plasma chambers (or plasma source chambers) are used, for example, by Thermo Fisher Scientific Inc. ) made iCAP 7000 TM in the mass spectrometer. The illustrated plasma chamber 10' comprises a housing 15 in which a plasma torch 31 is housed. The plasma torch 31 is provided with an RF inductive coil 38 arranged around a part of the length of the plasma torch 31 . The RF induction coil 38 serves as a heating element for generating the plasma. Viewing pieces 39 protrude from the side walls of the plasma chamber to allow side viewing of the plasma in use. The exhaust pipe 18 is arranged on the top wall of the plasma chamber 10 ′, and directly communicates with the exhaust port opening 29 located above the plasma torch 31 . A gas inlet opening 21 is provided in the bottom wall of the plasma chamber, adjacent to the side walls.

[0032] The location of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com