Audio-based intelligent fault diagnosis method for carrier roller of belt conveyor.

A belt conveyor, fault diagnosis technology, applied in voice analysis, sub-station installation, registration/indication of machine work, etc., can solve problems such as inability to detect various idler faults, low real-time performance, etc. The effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0055] The specific embodiments of the present invention will be further described in detail below with reference to the accompanying drawings.

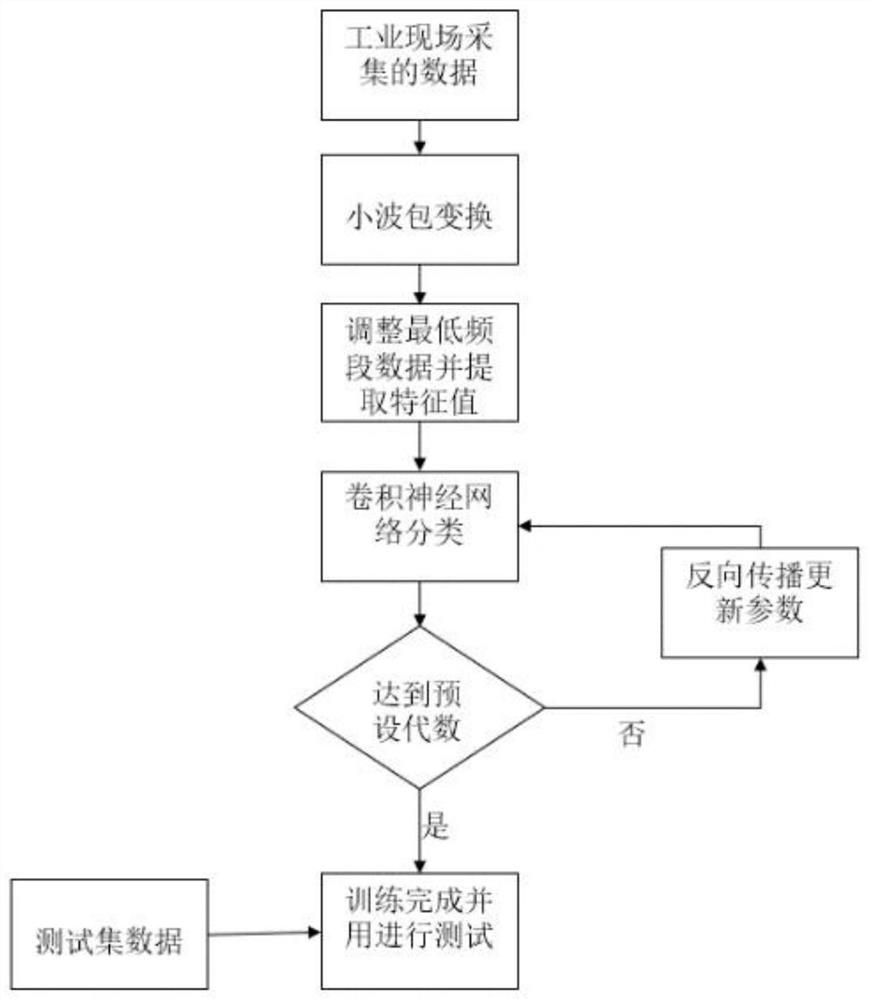

[0056] The present invention provides an audio-based intelligent fault diagnosis method for a belt conveyor idler, such as figure 1 shown, including the following steps:

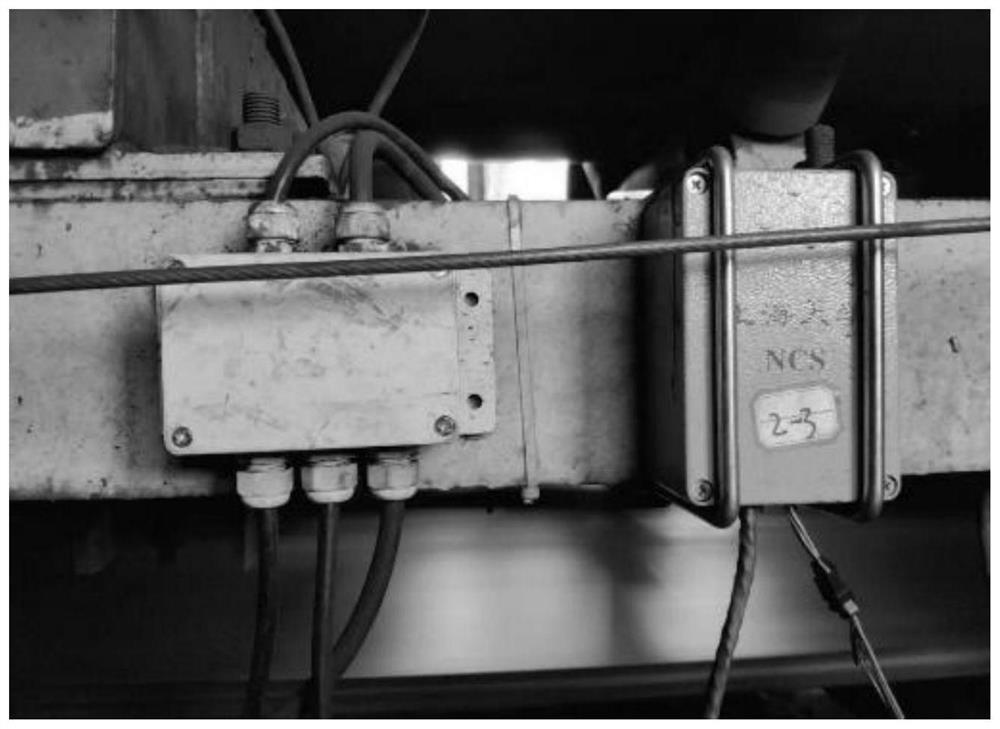

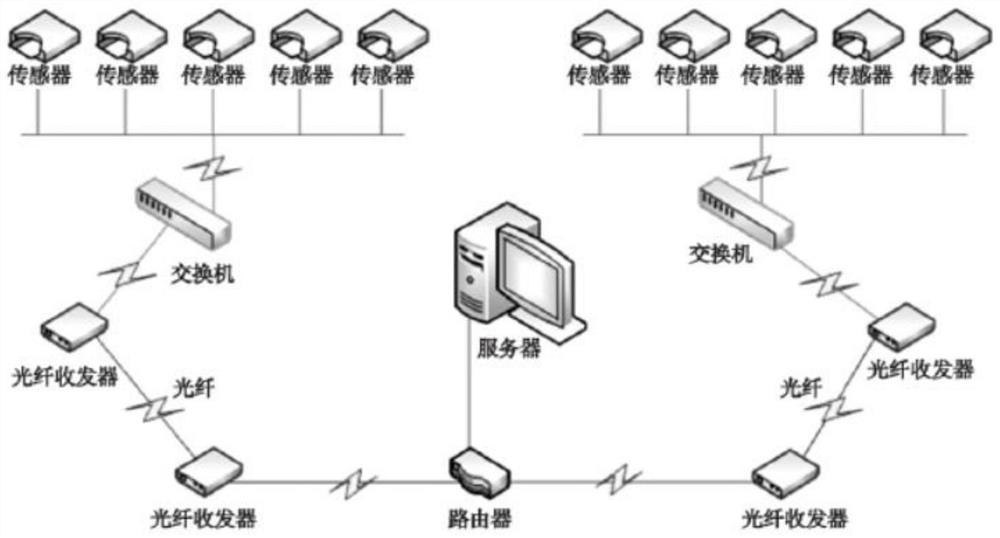

[0057] Step 1: Install the LM386 and Arduino Ethernet W1500 on the Arduino, and then install each Arduino with peripherals installed next to the roller;

[0058] Step 2: Connect the Arduino to the switch through optical fiber, so that multiple sensors are connected to one switch, and then transmit the signal;

[0059] Step 3: The audio data of the idler is transmitted to the terminal server through the switch and router, and the audio data of the idler is saved in the database at the same time;

[0060] Step 4: Preprocessing of the audio data of the idler: using the wavelet packet algorithm to preprocess the audio data of the idler, and divide the audio data into...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com