Intelligent manufacturing method and system for battery cell

A technology of intelligent manufacturing and battery cells, applied in secondary battery manufacturing, general control systems, control/regulation systems, etc., can solve problems such as the inability to intelligently adjust real-time parameters of battery cells, and achieve the effect of reducing the error rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

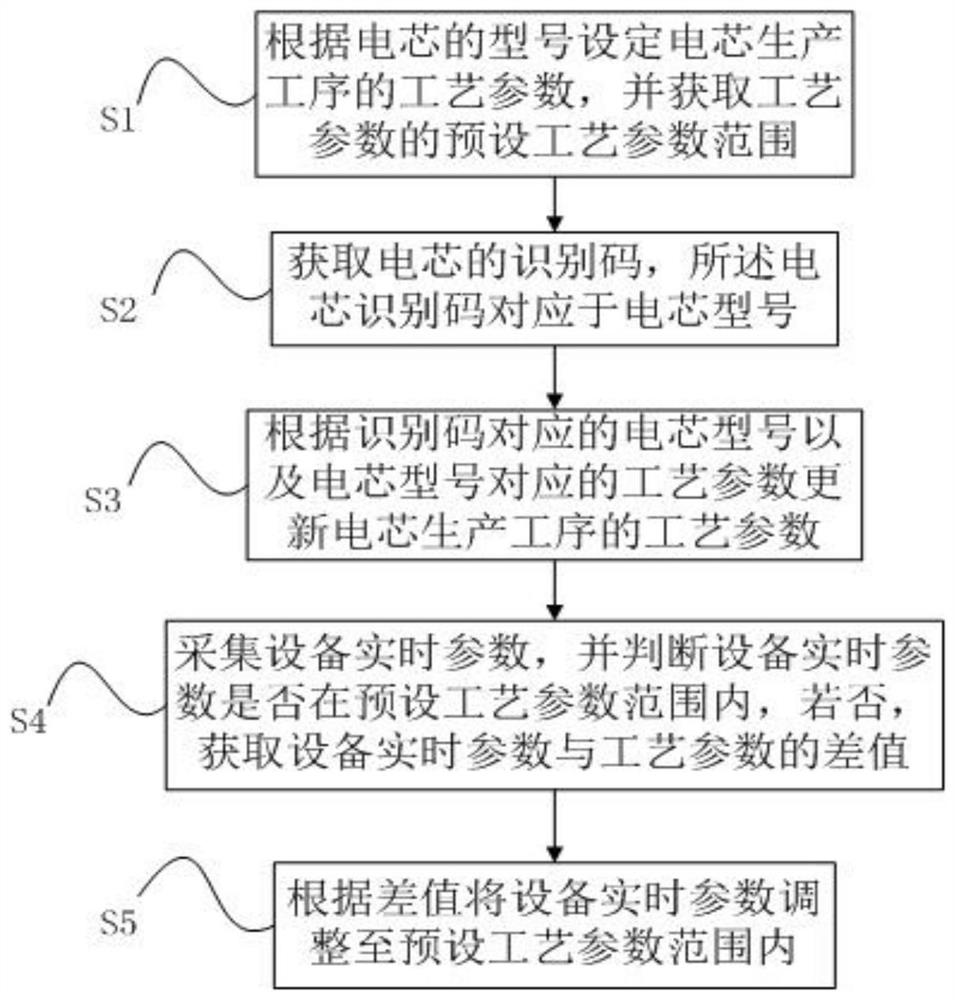

[0031] In order to reduce the setting time of the process parameters in the cell production process and realize the function of automatically correcting the real-time parameters of the equipment, the present invention sets and saves the process parameters of the cell production process according to the model of the cell, and through the real-time parameters of the equipment and the process The difference in parameters intelligently adjusts the real-time parameters of the battery production process equipment, which solves the need to reset the process parameters in the production process when the battery cell is changed in the current battery production process, and the inability to intelligently adjust the battery production process equipment Problems with real-time parameters such as figure 1 As shown, the present invention proposes an intelligent manufacturing method of a battery cell, comprising steps:

[0032] S1: Set the process parameters of the cell production process a...

Embodiment 2

[0045] In order to better understand the inventive idea of the present invention, this embodiment illustrates the present invention in the form of a system structure, such as figure 2 As shown, an intelligent manufacturing system for electric cells, the system includes a manufacturing execution unit, a device controller, and electric cell production process equipment, and is characterized in that it includes:

[0046] The parameter setting module is used to use the manufacturing execution unit to set the process parameters of the battery production process according to the model of the battery cell, and obtain the preset process parameter range of the process parameters;

[0047] In this embodiment, the two-sealing process in the cell production process and the cell whose identification code is H10322WPZ039333 and whose model is 376178PU are taken as examples for illustration.

[0048] In the second sealing process, there are three kinds of head temperature parameters, name...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com