A precise detection method for geological structures based on directional-while-drilling phase change vector seismic measurement

A technology of geological structures and detection methods, applied in seismology, measurement devices, seismic signal processing, etc., can solve problems such as difficulty in identifying geological structures, limitations on the accuracy of 3D seismic exploration, and difficulty in accurate detection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below.

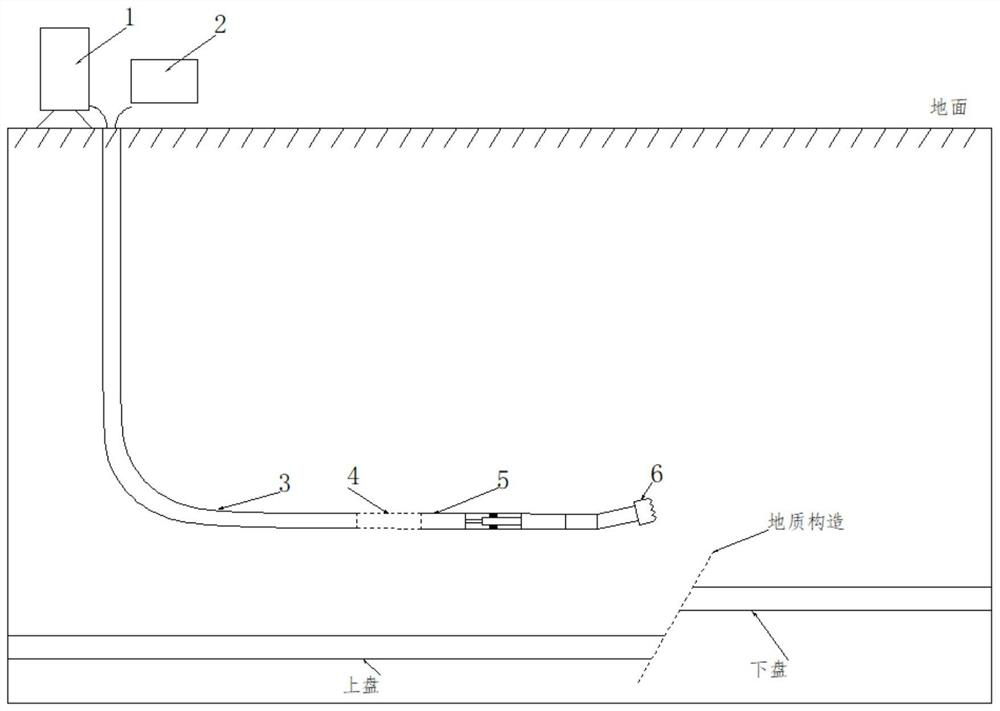

[0031] Such as figure 1 with figure 2 Shown, with the drilling direction of directional drill bit as the front is described, and concrete steps of the present invention are:

[0032] Step 1. Preliminary delineation of the detection area: use geophysical detection methods on the ground to find out the general distribution of underground geological structures, and delineate multiple target areas of geological structures to be accurately detected;

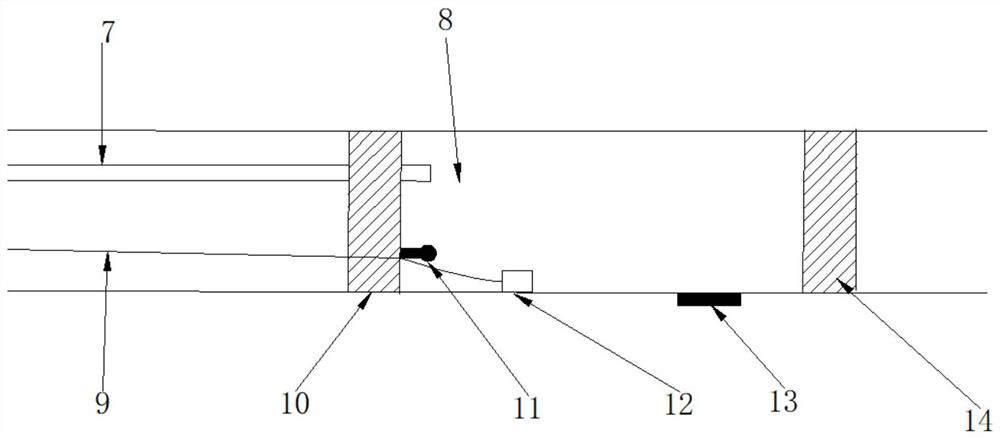

[0033] Step 2, assemble the directional detection equipment: connect the front end of the non-magnetic drill rod 5 with the directional drill bit 6, connect the rear end of the conventional drill rod 3 with the drilling machine, and install a phase change vector between the conventional drill rod 3 and the non-magnetic drill rod 5 The seismic device 4, the front end of the phase change vector seismic device 4 is coaxially connected with the rear end of the non-magnetic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com