Anti-falling structure and method for compressor silencer and compressor

A kind of anti-dropping structure and technology of compressor, applied in the direction of machine/engine, mechanical equipment, liquid variable capacity machinery, etc., can solve the problems of high discharge pressure of compressor, reduced performance of refrigerator, inconsistent vibration frequency, etc. Reasonable setting, improved reliability, compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

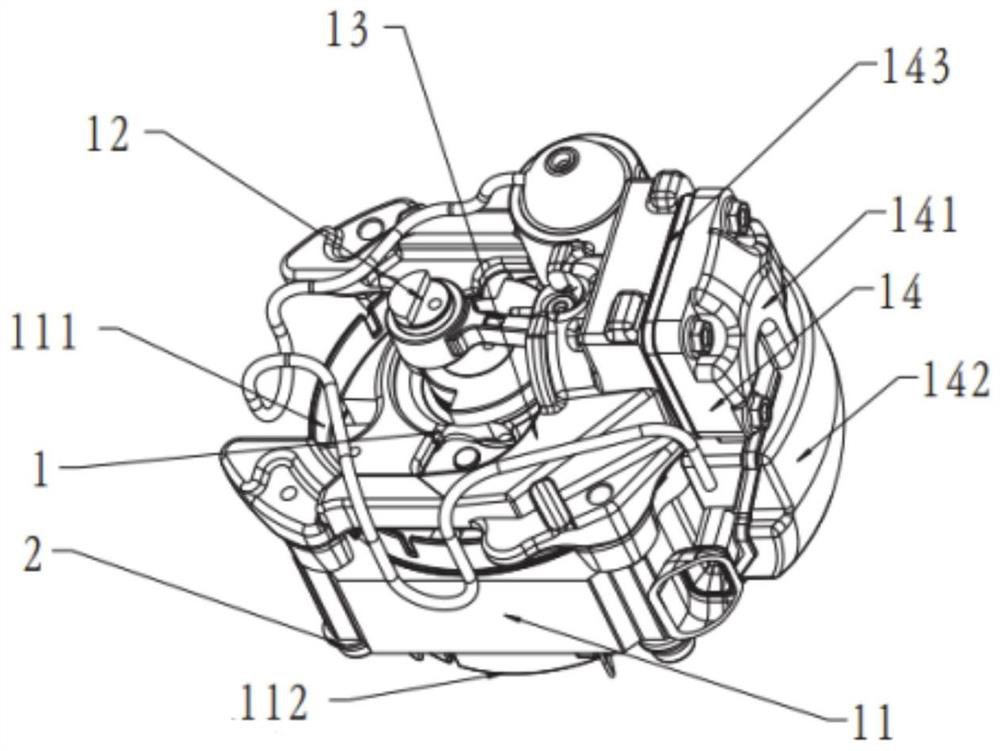

[0039] In a typical embodiment of the present invention, refer to figure 1 As shown, a compressor muffler anti-detachment structure includes a connecting piece 5 connecting at least two components at the compressor core 1 and the muffler. One end of the connecting piece 5 is connected to the compressor core 1, and the other end is connected to the silencer. Device 142 is connected.

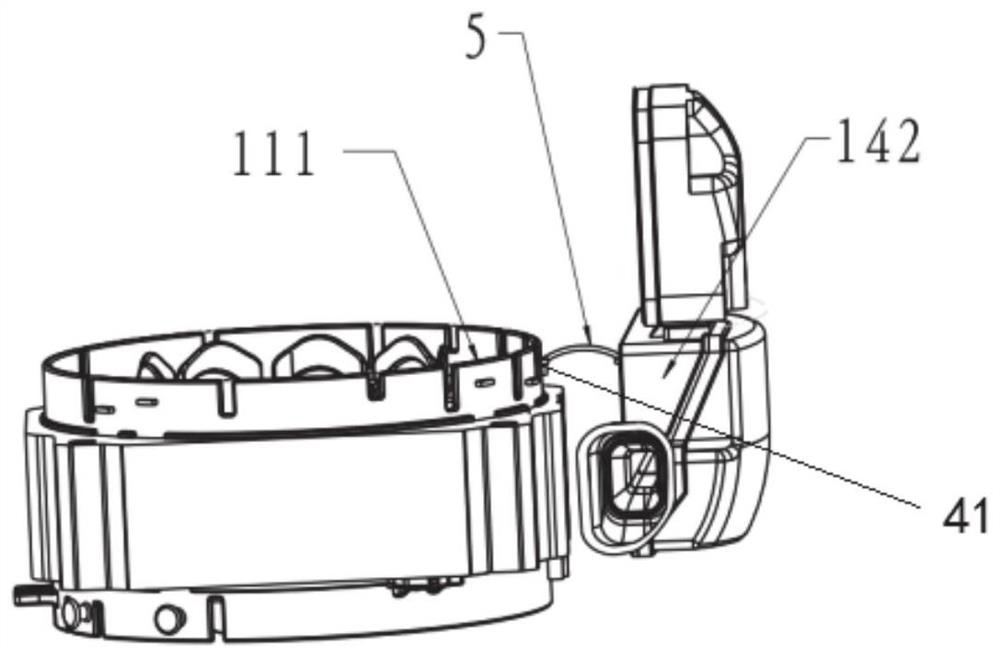

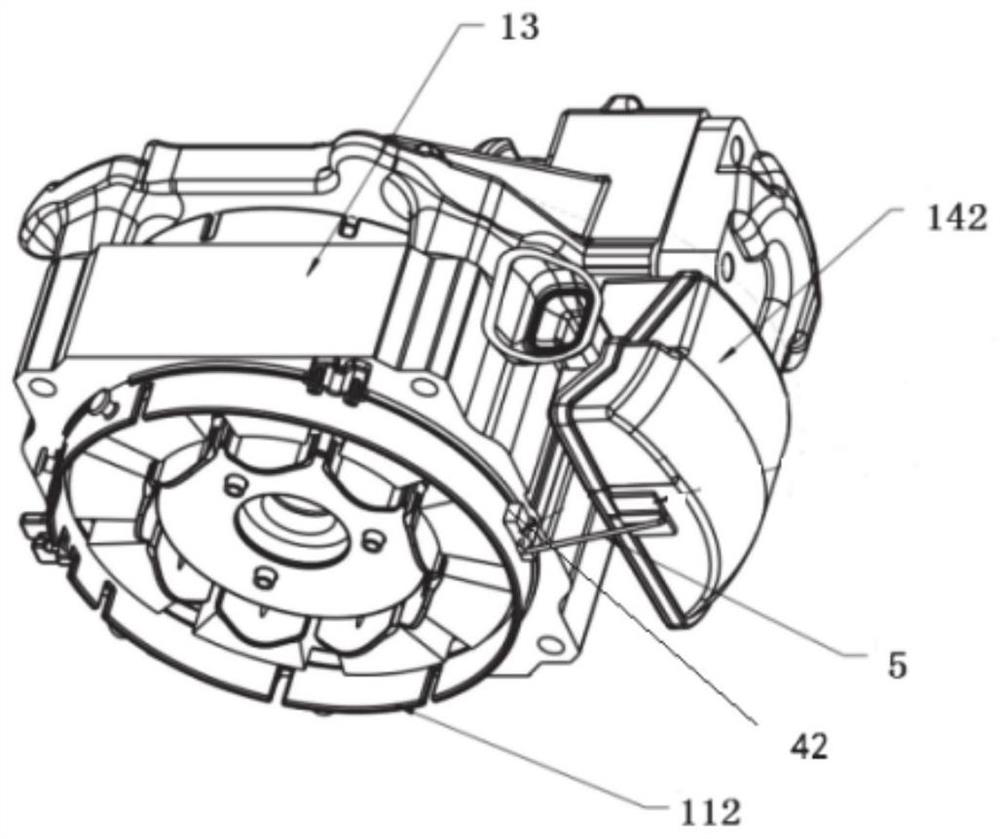

[0040] Specifically, refer to Figure 2-Figure 3 As shown, the connecting piece 5 includes a first connecting piece and a second connecting piece. The first connecting piece connects the upper frame 111 of the compressor motor at the compressor core and the muffler 142. The first connecting piece realizes the connection between the muffler and the compressor core. Indirect connection, the second connecting piece connects the lower frame 112 of the compressor motor at the compressor core and the muffler 142, the setting of the second connecting piece further realizes the indirect connection betwee...

Embodiment 2

[0060] The present invention also provides a compressor, including a compressor muffler anti-detachment structure in Embodiment 1. The compressor is composed of a core 1 and a support 2. The core is composed of a motor 11, a mechanical moving part 12, and a cylinder seat. 13. The cylinder head part 14 is composed of a motor upper frame 111 and a motor lower frame 112. The cylinder head part is composed of a cylinder head 141, a muffler 142, and a valve group 143. The compressor core is connected indirectly. Indirect connection is adopted, and multiple parts of the movement are connected to the muffler by multi-point support through spring steel wires.

Embodiment 3

[0062] The present invention also provides a compressor. The muffler 142 is connected with at least two parts of the motor upper frame 111, the motor lower frame 112, and the cylinder block 13 of the compressor core 1 by direct connection, so as to realize multiple The point support realizes the direct connection between the muffler 142 and the relevant components of the compressor core, ensuring the stability of the muffler setting.

[0063] Specifically, the ring clamping method can be adopted, and the ring clamping structure can be realized by setting the ring clamping structure at the corresponding positions of the motor upper frame 111, the motor lower frame 112, the cylinder seat 13 and the side of the muffler 142. Of course, it can also be used For other clamping methods, as long as the stable support connection to the muffler can be realized; the multi-point support to the muffler is realized by direct connection, and the components at the compressor core are fully util...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com