Acid soil conditioner as well as preparation method and application thereof

A technology of acidic soil and improver, which is applied in the direction of biochemical equipment and methods, applications, soil conditioning materials, etc., can solve problems such as difficult to achieve both symptoms and root causes, single effect, and secondary hazards, so as to promote improvement effects and improve medium and ability, the effect of improving fertility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

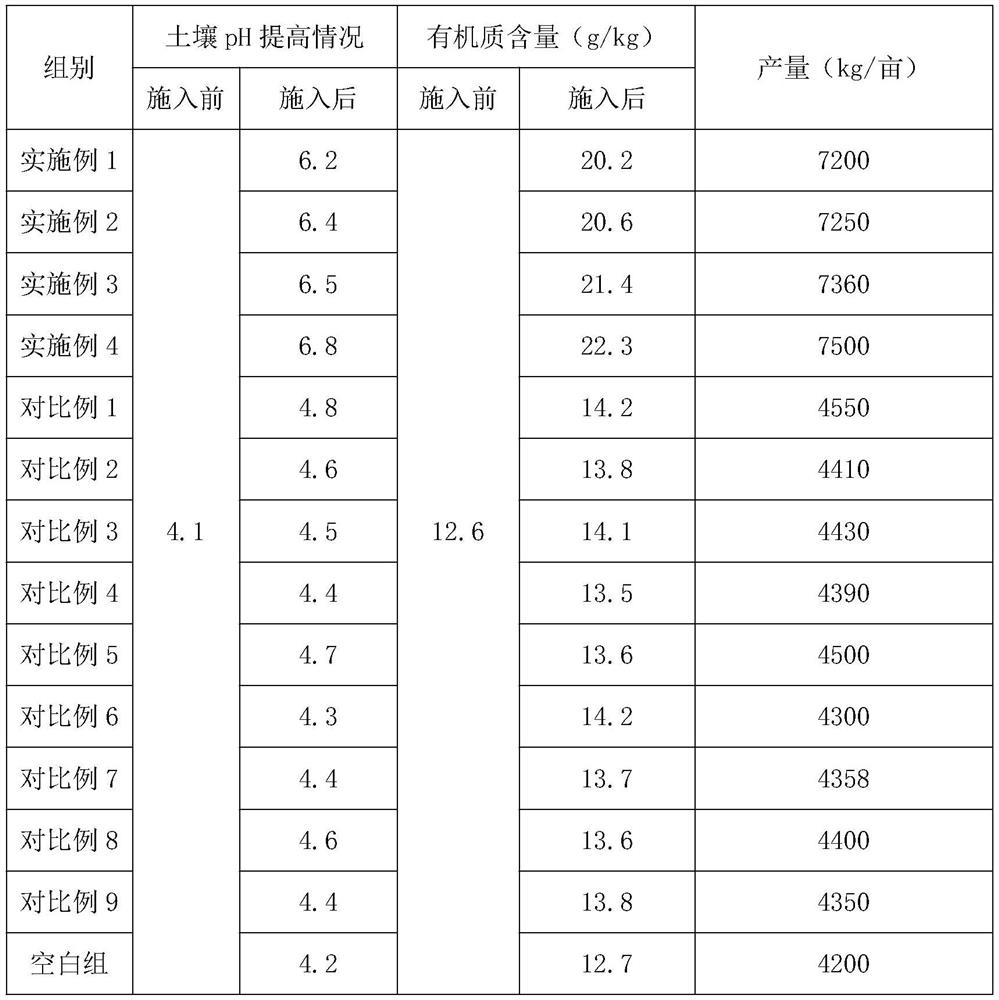

Examples

preparation example Construction

[0024] The present invention also provides a preparation method of the above-mentioned improver, comprising the following steps: mixing biochar, composite microbial agent, humic acid, animal manure and crushed quicklime with straw, and controlling the moisture content of the mixture to be 12- 30%, fermented at 33-38°C for 6-8 days, dried to constant weight under natural conditions, and crushed to obtain the improver.

[0025] In the present invention, there is no special limitation on the crushing method of quicklime and straw, and the conventional method of crushing quicklime and straw in the field can be adopted. In the present invention, after the quicklime is crushed, it is preferably passed through a 200-400 mesh sieve, and the crushed particle size of the straw is preferably 5-10mm. The moisture content of the mixture is preferably 15-25%, more preferably 20-22%. In the present invention, the temperature of the fermentation is preferably 35-37°C, more preferably 36°C, a...

Embodiment 1

[0034] Take quicklime, crush it and pass it through a 200-mesh sieve to get quicklime powder; take wheat straw and grind it to 5mm to get wheat straw powder.

[0035]Corn stalks were crushed to 10 mm, cracked at 150°C for 1 hour, then the temperature was raised to 400°C, and ammonia gas was continuously fed in, and biochar was obtained after activation for 4 hours.

[0036] Inoculate the complex bacteria of yeast and Bacillus subtilis with a mass ratio of 1:3 into the liquid fermentation medium (sucrose 10g / L, beef extract 10g / L, corn flour 20g / L, NaCl 10g / L, water), Cultivate at 32°C and 150r / min for 24 hours to obtain a complex bacterial fermentation liquid, and air-dry under natural conditions until the total number of effective viable bacteria is not less than 100 million / g to obtain a complex microbial agent.

[0037] Mix 10kg of wheat straw powder, 2kg of quicklime powder, 9kg of biochar, 0.5kg of compound microbial agent, 20kg of peat-derived humic acid and 8kg of pig m...

Embodiment 2

[0039] Take quicklime, crush it and pass it through a 400-mesh sieve to get quicklime powder; take peanut straw and grind it to 10mm to get peanut straw powder.

[0040] Corn stalks were crushed to 15mm, cracked at 280°C for 2 hours, then the temperature was raised to 580°C, and ammonia gas was continuously fed in, and biochar was obtained after activation for 5 hours.

[0041] The compound bacteria of yeast and Bacillus subtilis that mass ratio is 2:7 is inoculated in the liquid fermentation medium (sucrose 15g / L, beef extract 15g / L, corn flour 30g / L, NaCl 15g / L, water), Cultivate at 35°C and 200r / min for 42 hours to obtain a complex bacterial fermentation liquid, and air-dry under natural conditions until the total number of effective viable bacteria is not less than 100 million / g to obtain a complex microbial agent.

[0042] After mixing 30kg of peanut straw powder, 10kg of quicklime powder, 25kg of biochar, 1kg of compound microbial agent, 40kg of weathered coal-derived hu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com