Electrolytic solution additive for improving high and low temperature performance of lithium battery, preparation method of electrolytic solution additive, electrolytic solution and electrochemical device

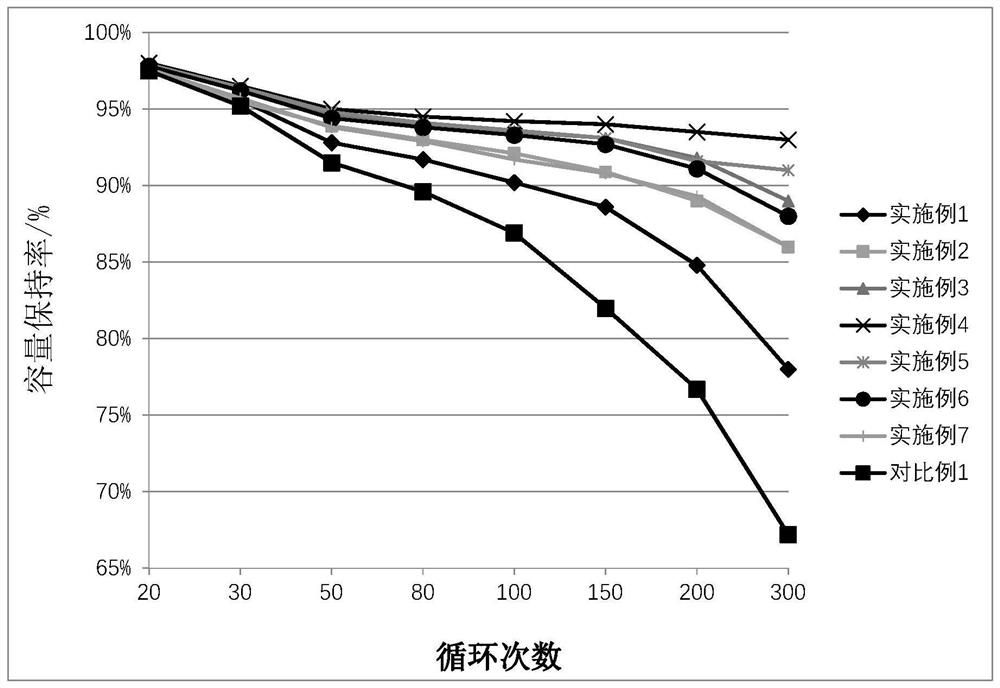

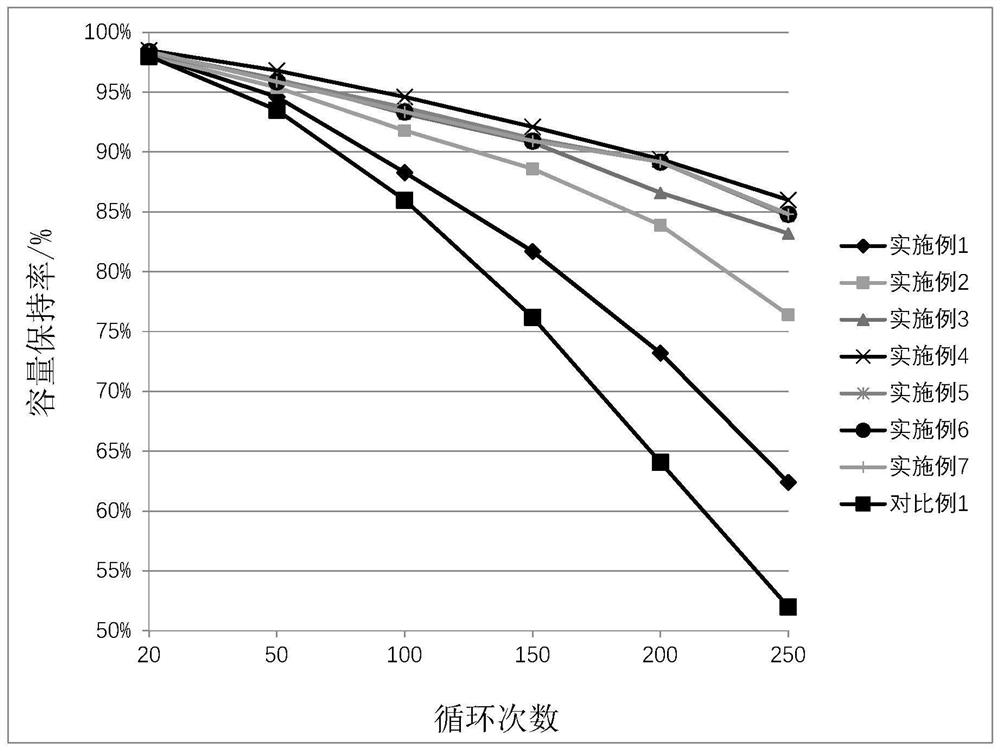

An electrolyte additive and electrolyte technology, applied in the field of lithium batteries, can solve the problems of lithium battery discharge capacity decline, affect the positive electrode active material, destroy the negative electrode SEI film, etc., and achieve the effect of slowing down the decline and high cycle capacity retention rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

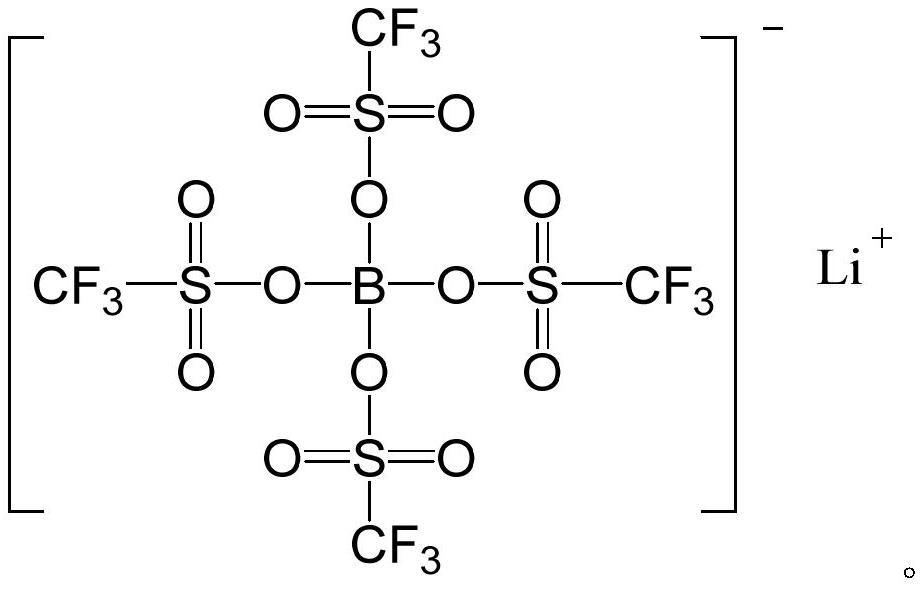

[0039] In a second aspect, the application provides a method for preparing the above-mentioned electrolyte additive, which includes the following steps: using lithium tetrachloroborate (Li(BCl) with a molar ratio of 1:(4.0~4.5), preferably 1:4.2 4 )) and trifluoromethanesulfonic acid (HOSO 2 CF 3 ) is dissolved in dichloromethane, stirred and reacted at 0-10°C for 6h-20h, and then the obtained mixed solution is rotary-evaporated at 35°C-50°C, preferably at 40°C to remove dichloromethane and by-product HCl, etc., The electrolyte additive is obtained.

[0040] Through the above method, the electrolyte additive according to the present application can be produced simply and conveniently, and its yield can be as high as 80%-90%.

[0041] In a third aspect, the present application provides a lithium battery electrolyte, which includes an electrolyte lithium salt, an organic solvent, and the electrolyte additive according to the above-mentioned first aspect or the electrolytic sol...

preparation Embodiment 1

[0072] Adopt following method to prepare electrolyte additive according to the application:

[0073] Lithium tetrachloroborate (Li(BCl) with a molar ratio of 1:4.2 (weight ratio of 1:3.95) 4 )) and trifluoromethanesulfonic acid (HSO 3 CF 3 ) was dissolved in dichloromethane, and NaHCO was added to it 3 Saturated solution, stirred and reacted overnight (12h) at 5°C, and then the obtained mixed solution was rotary evaporated at 40°C to remove dichloromethane and by-product HCl, thereby preparing the electrolyte additive according to the present application.

Embodiment 1

[0075] A mixed solvent of ethylene carbonate (EC), ethyl methyl carbonate (EMC) and dimethyl carbonate (DMC) with a weight ratio of 1:1:1 is used as the organic solvent of the lithium battery electrolyte, and lithium hexafluorophosphate (Lithium hexafluorophosphate) is added thereto. LiPF 6 ), vinylene carbonate (VC), fluoroethylene carbonate (FEC) and the electrolyte additive according to the application prepared in Preparation Example 1, so that LiPF 6 The concentration of VC and FEC is 1.0mol / L, the concentration of VC and FEC is 2.5wt%, and the concentration of the electrolyte additive according to the application is 0.2wt%, thus obtaining the lithium battery electrolyte.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com