High-altitude operation equipment for ship coating

A high-altitude operation and painting technology, which is applied to ship cleaning devices, metal processing equipment, hulls, etc., can solve the problems of backward operation methods such as large environmental hazards and low manual work efficiency, so as to eliminate the risk of high-altitude operations, save water and electricity energy, The effect of improving the quality of work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

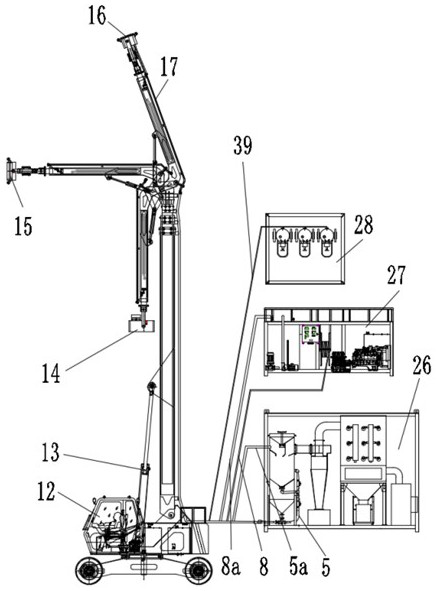

[0031] Such as Figure 1-Figure 6As shown, the embodiment of the present invention provides a kind of high-altitude operation equipment for ship painting, which is mainly used for derusting and cleaning operations, sandblasting and derusting operations, high-pressure water derusting operations, and painting paints for hull panels and cargo holds in shipyards A multi-purpose platform for spraying operations. This equipment mainly includes a walking integrated platform body, a sandblasting and waste sand sealing recovery mechanism 26, an ultra-high pressure water and sewage recovery mechanism 27, and a painting mechanism 28. The walking integrated platform body includes a driving car 3, a driving car The four corners of the bottom of 3 are connected with wheels 1 through steering fork 18, and the top of driving car 3 is connected with slewing platform through slewing support 21. Operating room 12, engine and hydraulic oil pump 23 are installed on the slewing platform, and engine ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com