Harmless disposal system for mine tailings

A disposal system and technology for mine tailings, which are applied in mining equipment, safety devices, earth-moving drilling, etc., can solve the problem of unstable surrounding rock conditions in underground goafs, low comprehensive utilization rate of tailings, and recycling rate of tailings wastewater. Low-level problems, to prevent surface collapse, ensure filling effect, and have obvious advantages in disposal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

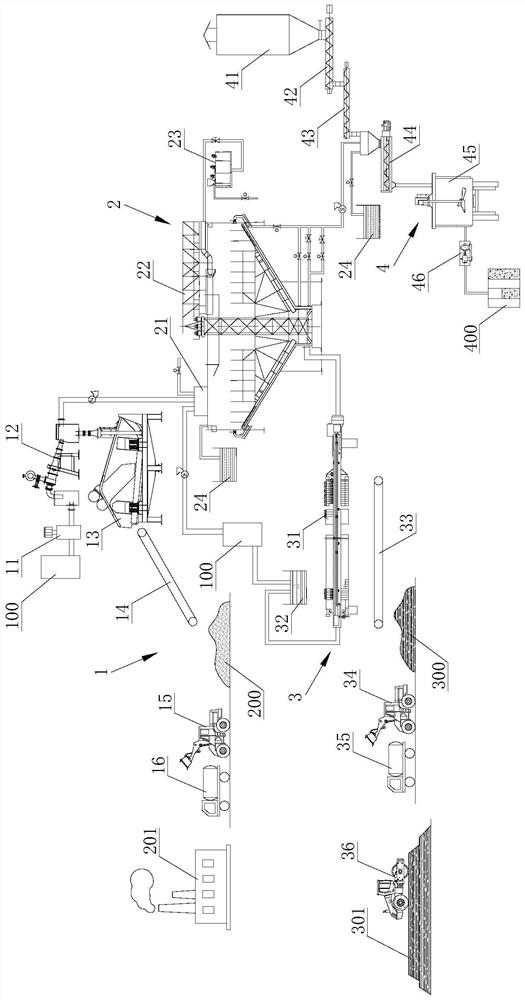

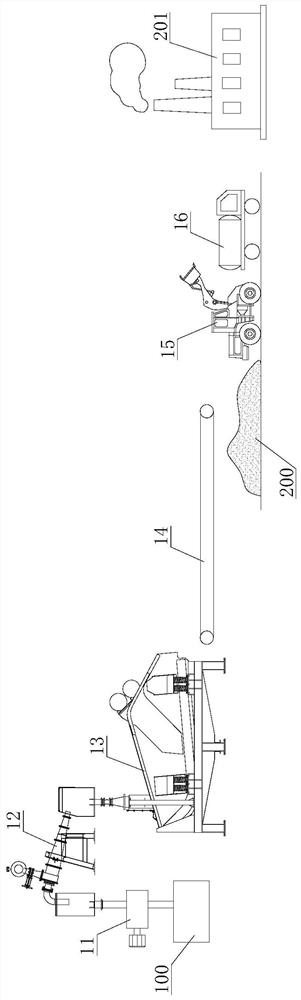

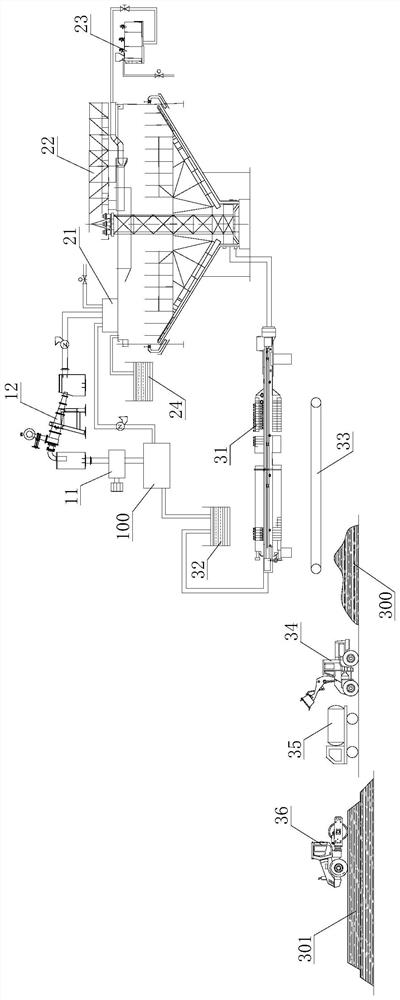

[0017] Please refer to Figure 1 to Figure 4 As shown, the present invention provides a harmless disposal system for mine tailings, including a tailings preparation mechanism 1 for dry sand disposal, a fine-grained high-concentration tailings concentration mechanism 2, a filter cake preparation tailings mechanism 3 and a fine-grained tailings preparation mechanism. Sand cemented filling body disposal tailings mechanism 4, the preparation dry sand disposal tailings mechanism 1 includes a slurry pump 11, a cyclone 12 and a high-frequency vibrating dewatering screen 13, and the slurry pump 11 converts the whole tailings mortar of the dressing plant 100 is pumped to the cyclone 12 in the plant for classification, and the high-frequency vibrating dew...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com