Biological digestion treatment process for odor generated by kitchen waste treatment equipment

A technology for processing equipment and kitchen waste, applied in gas treatment, waste fuel, air quality improvement, etc., can solve the problems of difficult odor treatment, low digestion efficiency, high treatment cost, etc., to improve environmental protection value and save water. resources, the effect of improving economic value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

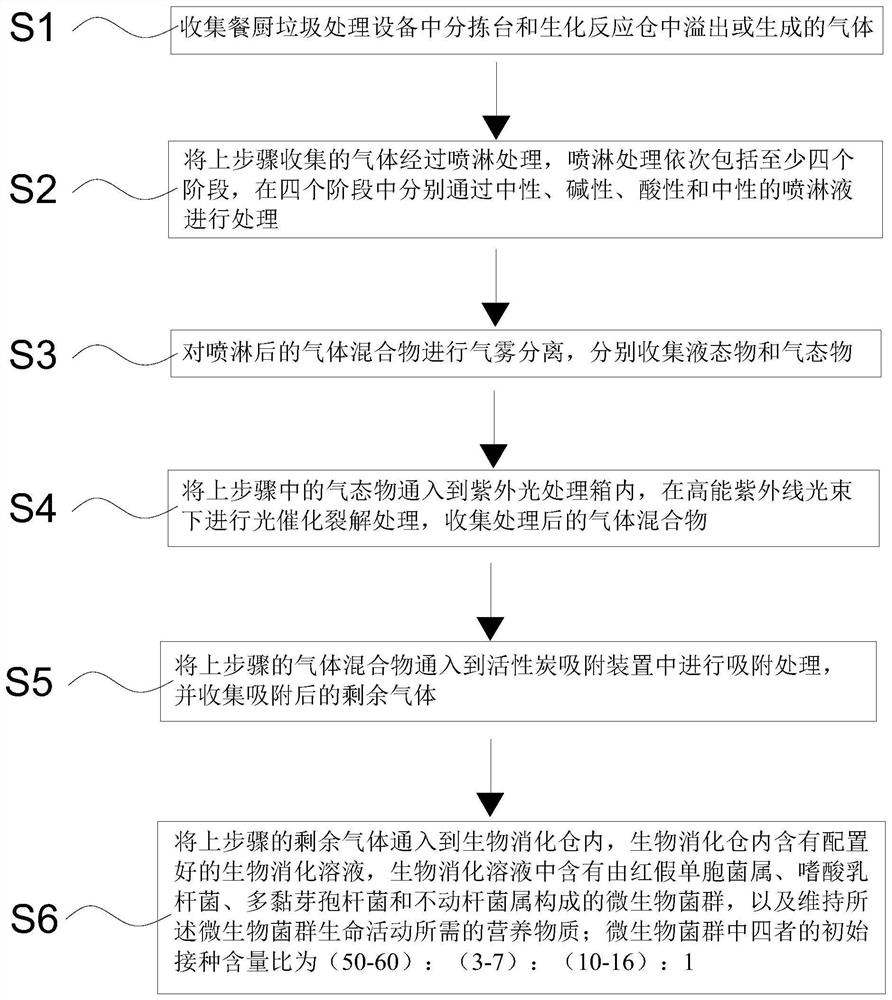

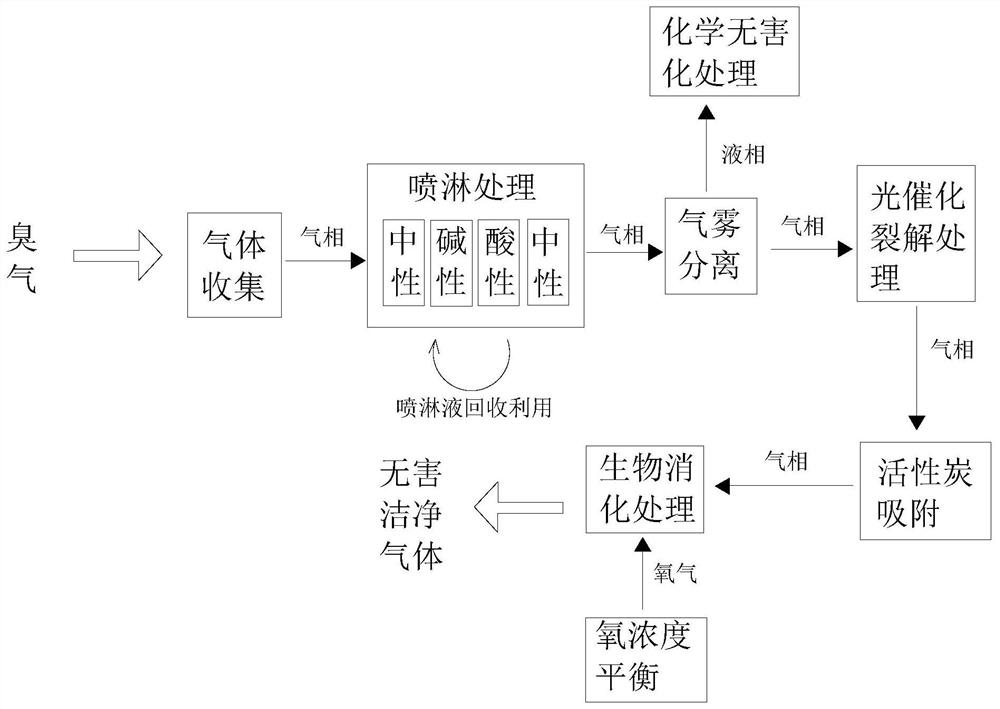

[0041] This embodiment provides a biodigestion treatment process for the odor generated by the food waste treatment equipment, which is applied to the odor digestion system for the food waste treatment equipment in Example 1. Such as figure 1 and 2 As shown, according to the processing sequence, the following processing steps are included in sequence:

[0042] S1: Collect the gas overflowing or generated in the sorting table and biochemical reaction chamber in the food waste treatment equipment.

[0043] S2: The gas collected in the above step is subjected to spraying treatment. The spraying treatment includes at least four stages in turn, and the four stages are respectively treated with neutral, alkaline, acidic and neutral spray liquids.

[0044] Wherein, the spray treatment process is completed in the spray tower, and the spray tower is selected to have four-stage spray chambers arranged horizontally. Wherein, a soda ash solution with a pH value greater than 8.5 and les...

Embodiment 2

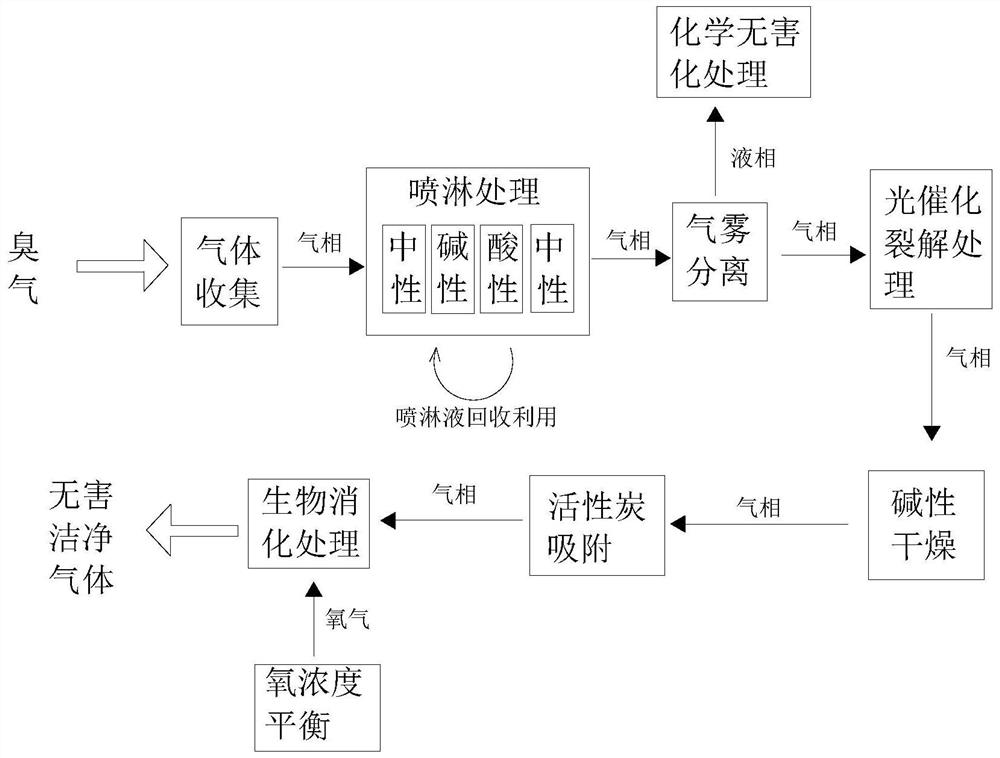

[0059] This embodiment provides an odor digestion system for kitchen waste treatment equipment. The system adopts the biological digestion treatment process in Embodiment 1 to treat odorous substances in kitchen waste. The system can fully digest all kinds of odorous substances produced in the process of food waste treatment, and achieve the effect of complete deodorization.

[0060] The food waste treatment equipment using the odor digestion system includes: unloading platform, sorting platform, crushing system, dehydration system, transmission system and biochemical reaction chamber. Among them, the sorting platform is used to sort out the non-degradable garbage in the kitchen waste; the biochemical reaction chamber is used to ferment the dehydrated solids of the kitchen waste and convert them into usable organic fertilizers.

[0061] Such as Figure 4-6 As shown, according to the sequence of the treatment process, the odor digestion system provided by the present invention...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com