Circulating purification device for acid for surface treatment

A technology for surface treatment and cyclic purification, applied in the direction of surface reaction electrolytic coating, anodizing, chemical instruments and methods, etc. In order to achieve the effect of thorough cleaning of the filter screen, improving filtration efficiency and automatic filtration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

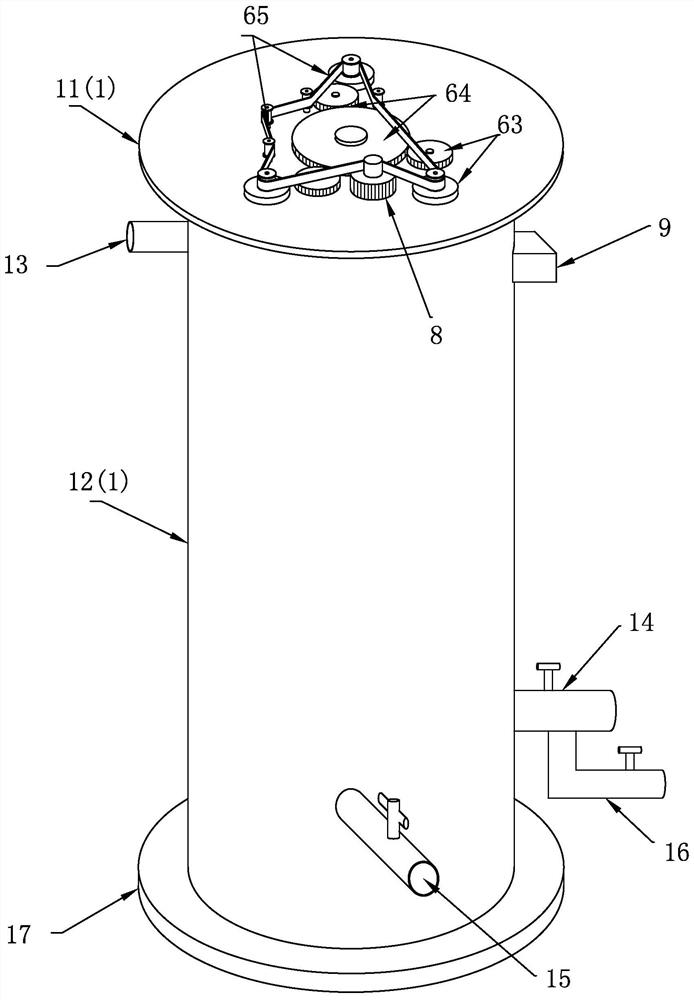

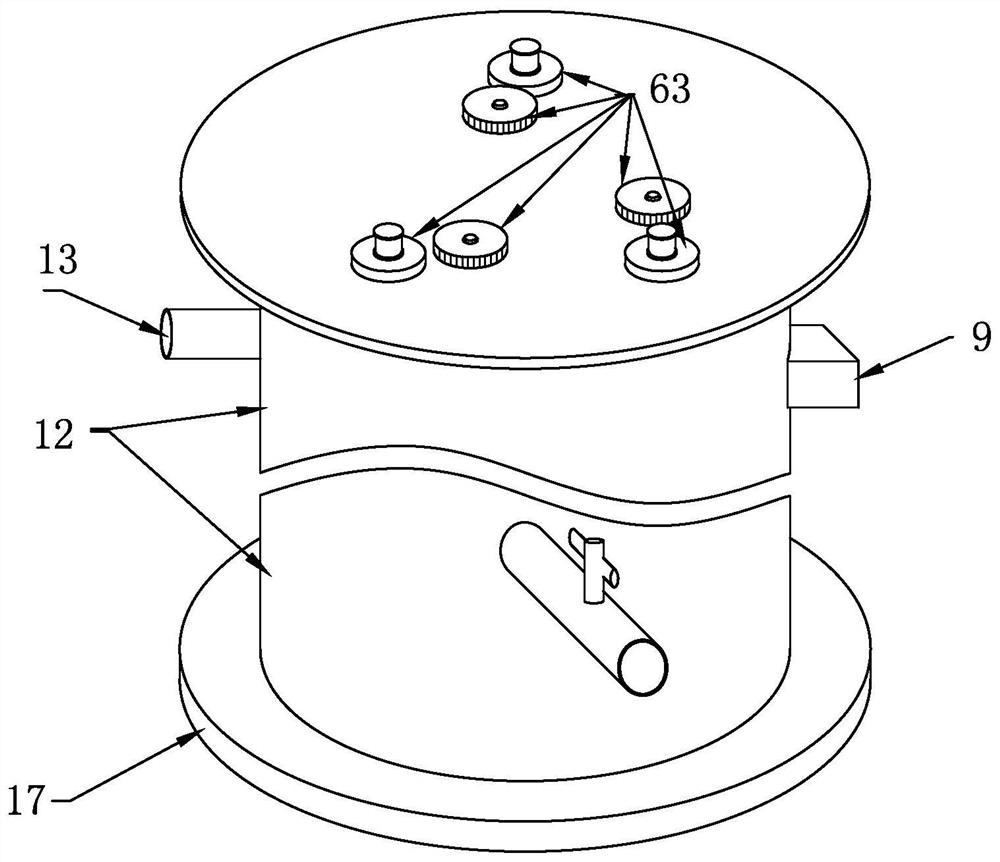

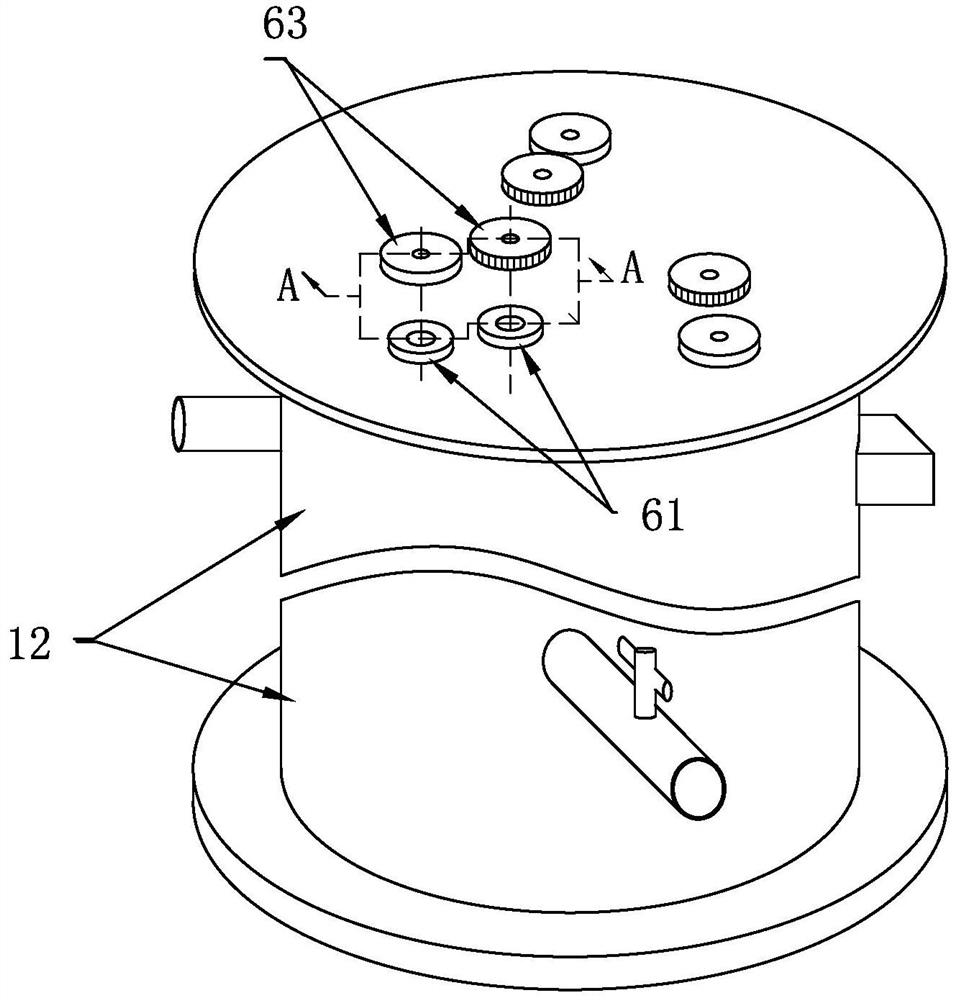

[0044] The acid circulation and purification device for surface treatment of the present invention comprises a casing 1 of a closed structure, a two-stage filter system arranged in the casing 1, and the main metal containing metals accumulated in each filter system according to the pressure value in the casing 1. Sludge impurities of floc and / or scale start the scraping device for the treatment operation.

[0045] 1. Housing 1

[0046] Such as figure 1 , Figure 14 As shown, it mainly includes a flange cover plate 11 made of 316# stainless steel and a cylindrical shell 12. Several screw holes are arranged around the flange cover plate 11, and the flange cover plate 11 and the shell tube 12 are connected by bolts. Fastened together. Because during the filtration process, the pressure inside the housing 1 will gradually increase due to the filter screen being blocked by acid scale, and the pressure inside the housing can reach 3-4kg at the highest, and because it is necessary...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com