Automatic filtering device and method as well as cleaning machine

An automatic filter and cleaning machine technology, which is applied in the field of automatic filter devices and cleaning machine equipment, can solve the problems of high cost of use, unfavorable environmental protection, and high labor intensity of employees.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

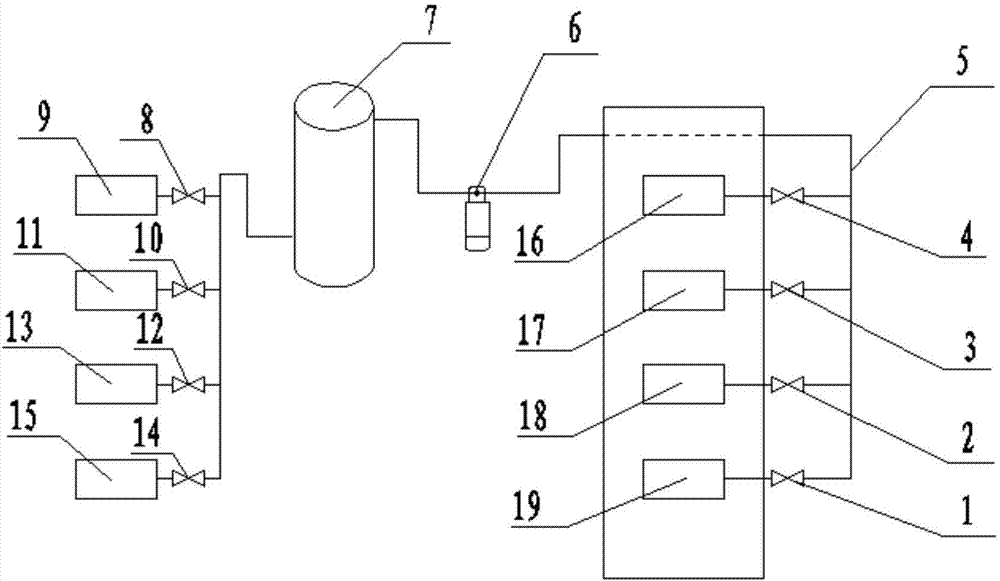

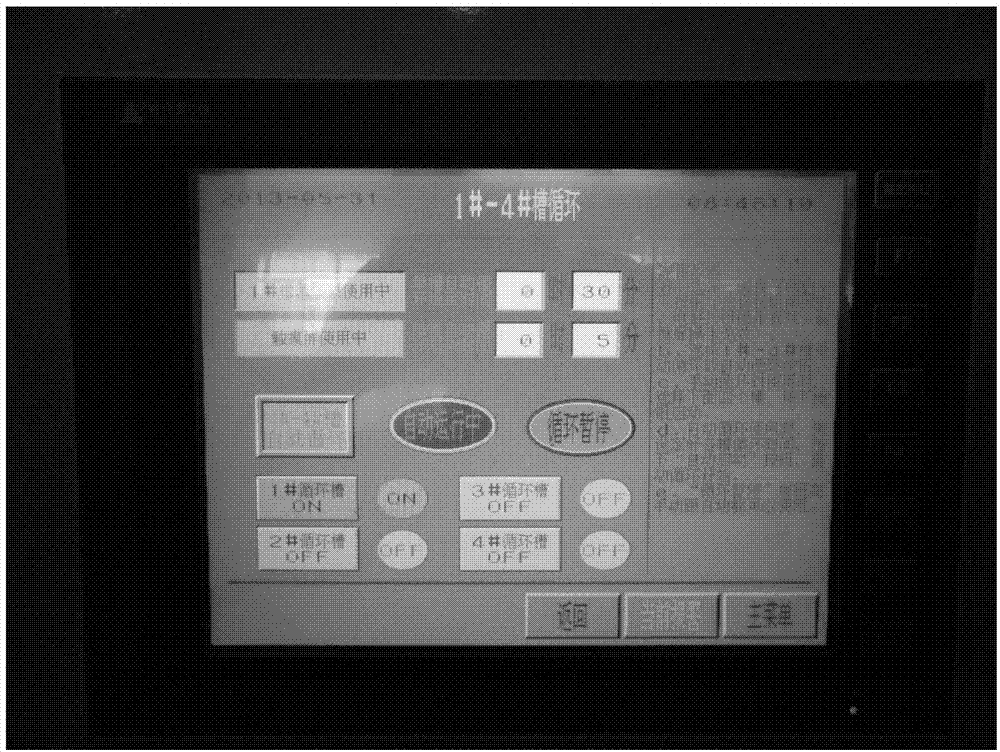

[0046] The invention provides an automatic filtering device, such as figure 1 As shown, it includes a filter 7, a filter pipeline 5, an electric control PLC, and a pump 6 electrically connected to the electric control PLC;

[0047] The electronically controlled PLC is used to send a control signal according to a preset program to control the operating state of the automatic filter device, and to drive the liquid pump 6 to operate to extract the cleaning liquid;

[0048] The filter pipeline 5 communicates with the inner tank of the cleaning machine and the outer tank of the cleaning machine;

[0049] The filter pipeline 5 is provided with a suction water pump 6 on the side of the inner tank, which is used to extract the cleaning liquid in the inner tank of the washing machine;

[0050] A filter 7 is arranged on the filter pipeline 5 at the side of the outer tank for filtering the cleaning liquid drawn by the liquid suction pump.

[0051] In the automatic filtering device of t...

Embodiment approach

[0052] As a possible implementation, the automatic filtering device also includes an electronically controlled valve for the inner tank and an electronically controlled valve for the outer tank;

[0053] The electric control valve of the inner tank is arranged on the inner tank side of the washing machine, and is electrically connected with the electric control PLC, and the number is at least one;

[0054] The outer tank electric control valve is arranged on the outer tank side of the washing machine and is electrically connected with the electric control PLC, and the number is at least one.

[0055] The electronically controlled PLC drives the electronically controlled valve of the inner tank and the electronically controlled valve of the outer tank to open. If the electric control valve of the tank is not opened, the cleaning liquid cannot be drawn from the inner tank, nor can it be delivered to the outer tank.

[0056] As a possible implementation, see figure 1 As shown, ...

Embodiment 2

[0073] In order to explain more clearly how the cleaning liquid filtering process is performed between the automatic filtering device of the present invention and the washing machine equipment, the present invention also provides an automatic filtering method, specifically illustrating the working process of the automatic filtering device.

[0074] An automatic filtering method, comprising the following steps:

[0075] The electronically controlled PLC sends control signals according to the preset program to control the operation status of the automatic filter device, drives the liquid pump to operate, and pumps the cleaning liquid in the inner tank of the cleaning machine to the filter pipeline;

[0076] The cleaning liquid flows into the filter through the filter pipeline, and the filter filters the cleaning liquid;

[0077] The filtered cleaning liquid flows through the filter pipeline on the other side of the filter to the outer tank of the cleaning machine.

[0078] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com