Micro-steaming oven with heating and backwashing functions

A backwashing and functional technology, applied in the field of micro-steaming ovens, can solve problems such as incoherent operation, affecting taste, and poor food quality, and achieve the effect of filling water and ensuring taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

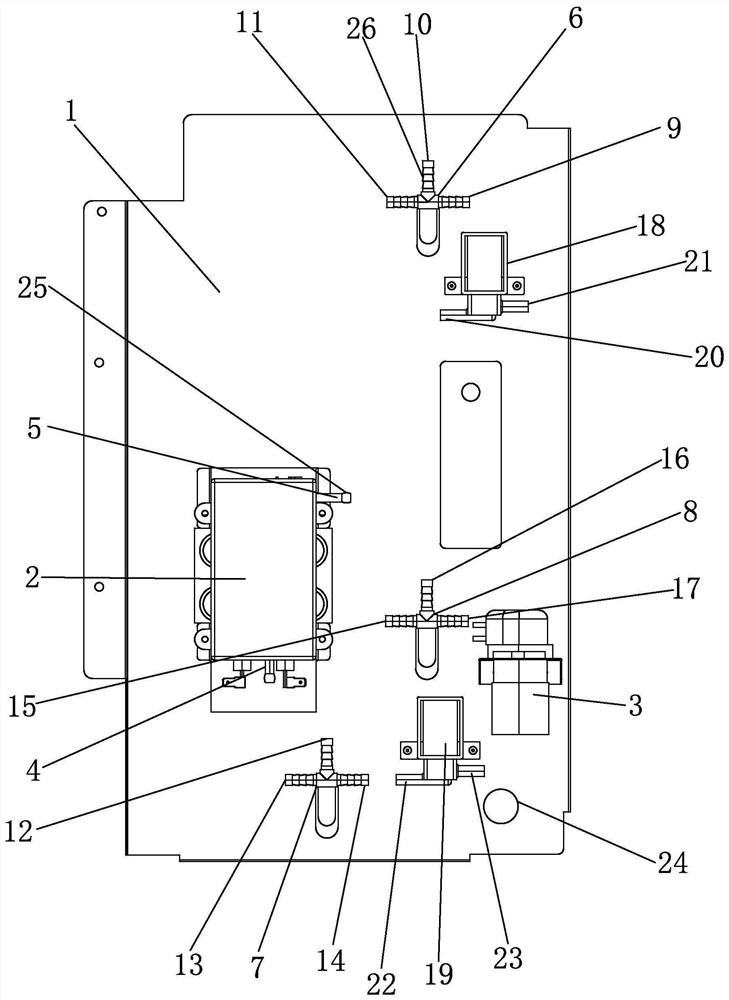

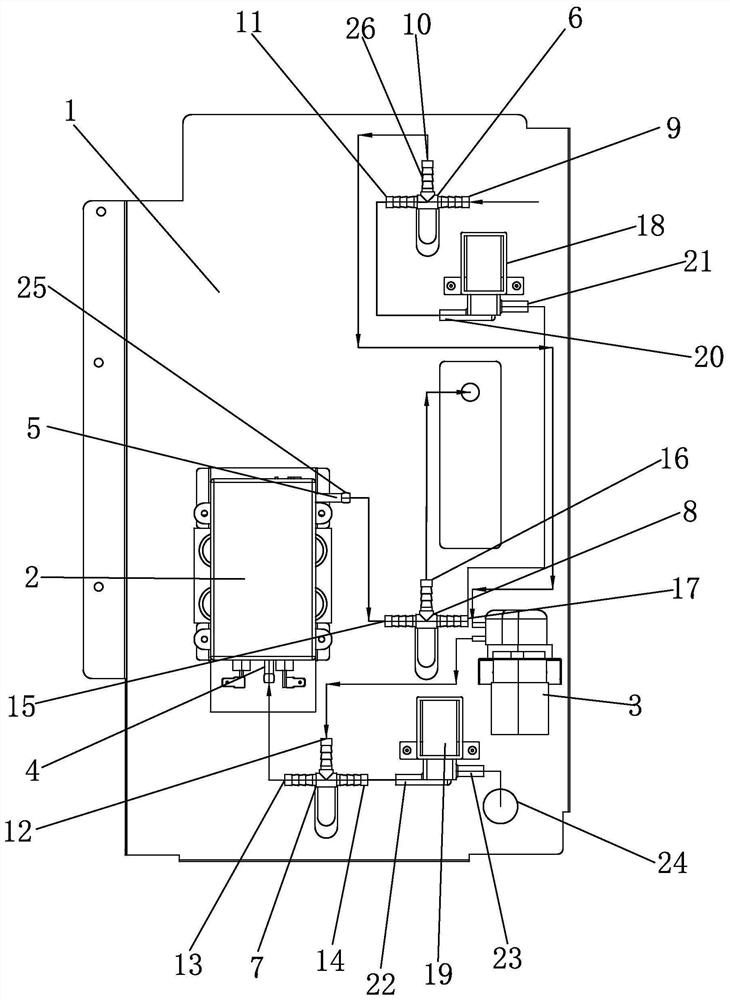

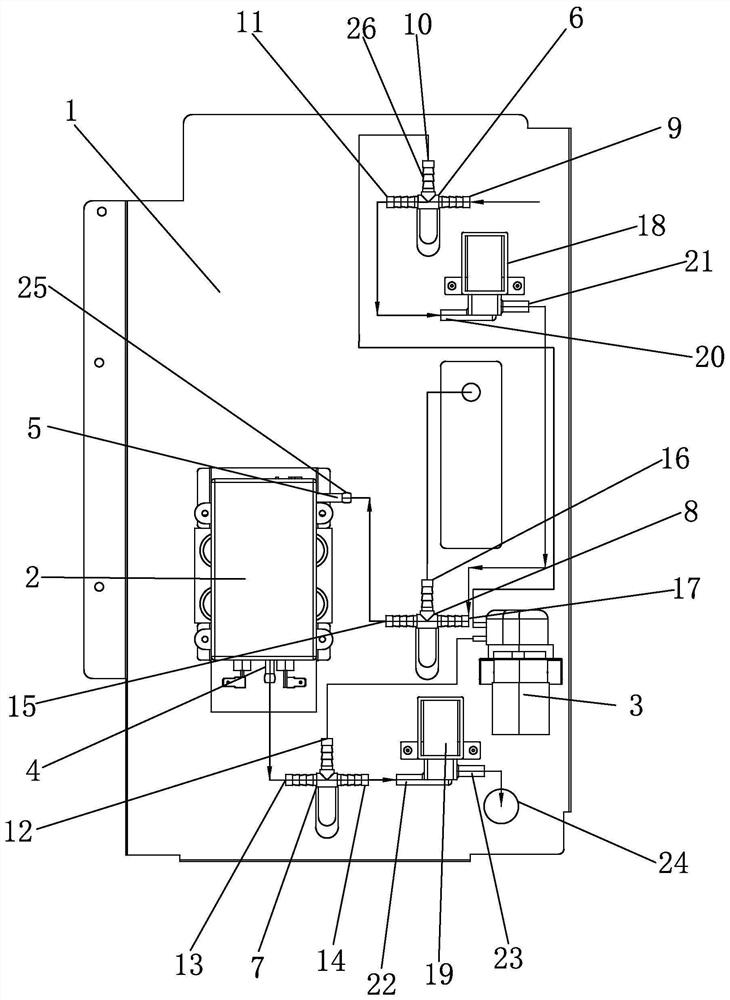

[0026] like Figure 1 to 3 As shown, it is a micro steam oven box having heating and backwashing function, including a steam generator 2 and a water pump 3 disposed on the liner 1 side; a pipe 3 is connected between the water pump 3 and the steam generator 2. The water pump 3 delivers water to the steam generator 2 in the steam generator 2, and the steam generator 2 is discharged into the inner bile 1 after the steam generator 2 is discharged into the inner bile 1.

[0027] The pipeline is provided with a first joint 6, the second joint 7 and the third joint 8, one joint 6, and the second connector 7 and the three joint 8 are all connected to the three-way joint, the first joint 6 is connected to the water pump 3, for Conveyed the external water source to the water pump 3; the second connector 7 is connected between the water pump 3 and the steam generator 2 to deliver the pressurized water to the steam generator 2; the three joint 8 and the steam generator 2 Connect to transport s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com