Pulverized coal spray head structure

A sprinkler and pulverized coal technology, which is applied in the directions of block/powder supply/distribution, burners for burning powder fuel, and combustion methods, etc. The problems such as the large degree of pulverized powder aggregation can be achieved to increase the consumption of pulverized coal, save coal resources and costs, and improve the utilization rate of pulverized coal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

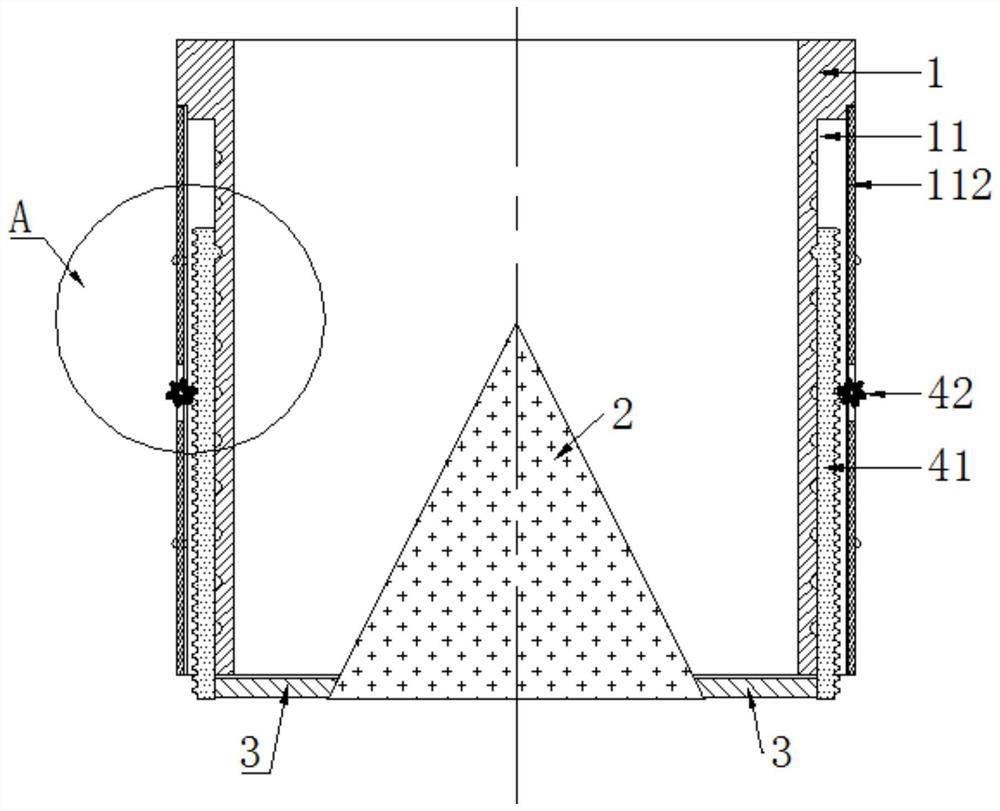

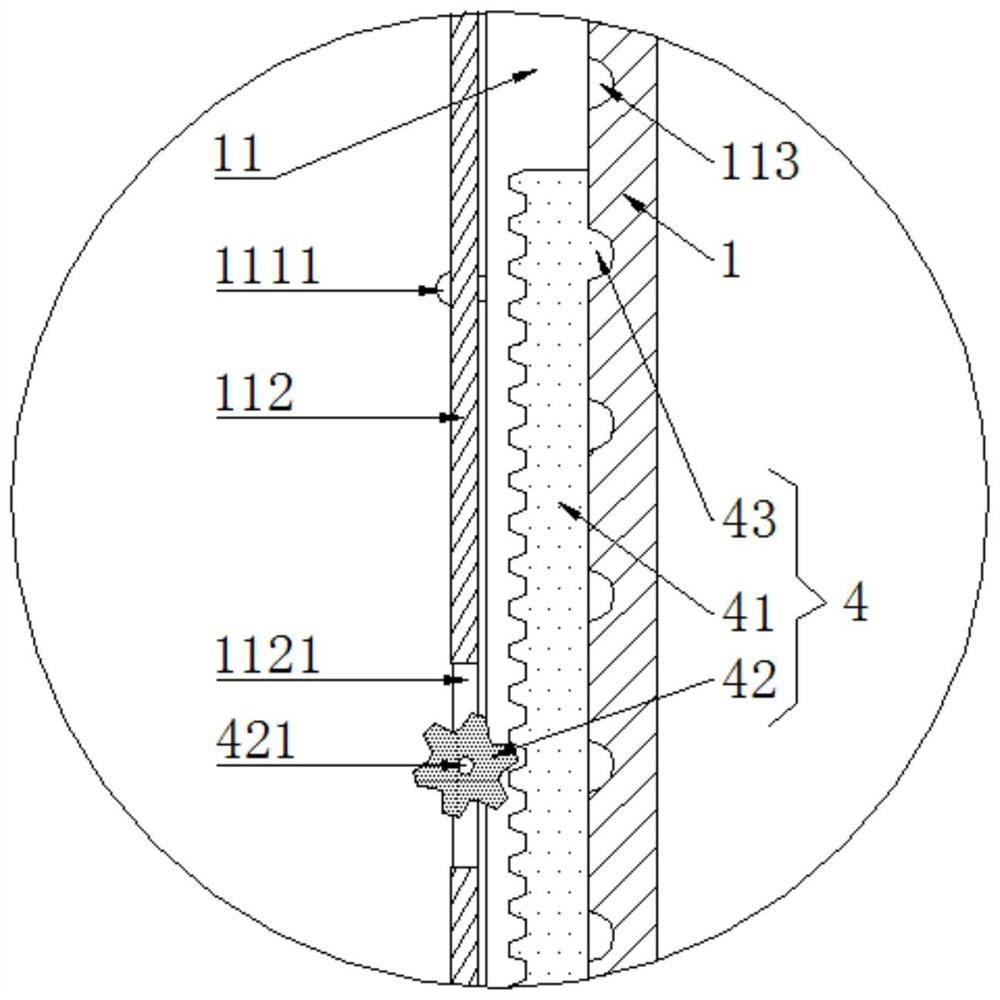

[0055] Such as Figure 2-5 As shown, a pulverized coal nozzle structure includes a nozzle 1 , a cone 2 , a support rod 3 , and a lifting mechanism 4 .

[0056] Such as figure 2 As shown, the spout 1 is provided with a conical block 2 with its tip facing upwards, and two support rods 3 are welded at the lower end of the conical block 2, and the support rods 3 are connected with the pipe wall of the spout 1 through a lifting mechanism 4.

[0057] Such as Figure 4 As shown, the setting of the cone block 2 can form an annular powder injection port between the side wall of the cone block 2 and the nozzle edge of the nozzle 1, so that the coal powder flowing through the cone block 2 is dispersed by the cone block 2, The dispersed pulverized coal is sprayed out in a ring after passing through the powder injection port, and the pulverized coal sprayed out in a ring can be more evenly dispersed, which improves the adequacy of the contact between the pulverized coal and the oxygen i...

Embodiment 2

[0071] Such as Figure 6-11 As shown, this embodiment 2 makes further improvements on the basis of embodiment 1: in the structure of a pulverized coal nozzle in this embodiment 2, the cone block 2 includes a cone riser 21, an adjusting screw 22, a first cone Side plate 23, second cone side plate 24, adjustment connecting rod 25, adjustment block 26.

[0072] Such as Figure 11 As shown, the upper end of the adjusting screw 22 is rotationally connected with the cone 21 . Concrete: the lower end of the cone riser 21 is provided with a rotating hole 211, the hole wall of the rotating hole 211 is provided with an annular groove 2111, the upper end of the adjusting screw rod 22 is welded with an annular rail 221, and the annular rail 221 can rotate with the annular groove 2111.

[0073] Such as Figure 11 As shown, when the adjustment screw 22 and the cone cap 21 need to be installed together, it is only necessary to squeeze the annular rail 221 on the adjustment screw 22 into t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com