Power generation system utilizing waste heat of marine diesel engine

A marine diesel engine and waste heat power generation technology, applied in electromechanical devices, machines/engines, generators/motors, etc., can solve problems such as failure to start, achieve long service life, reduce dependence, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

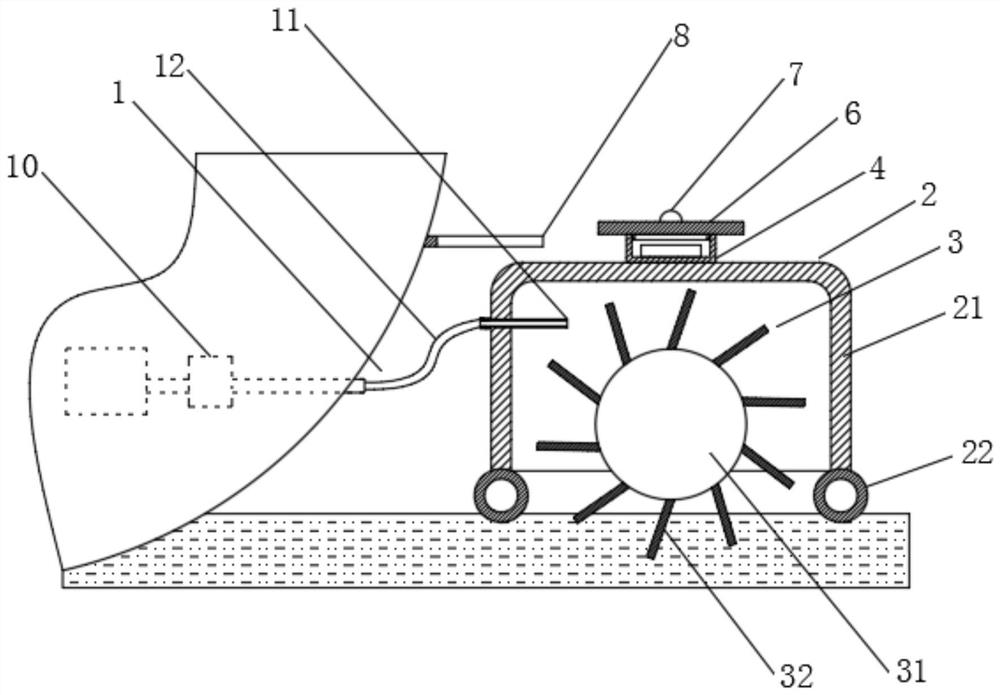

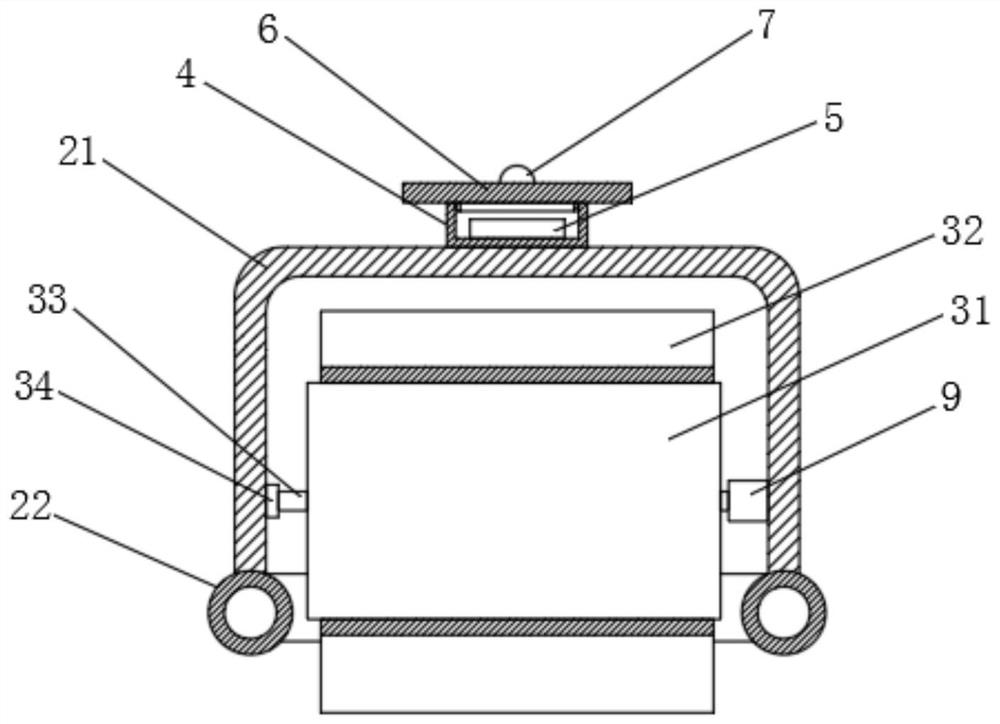

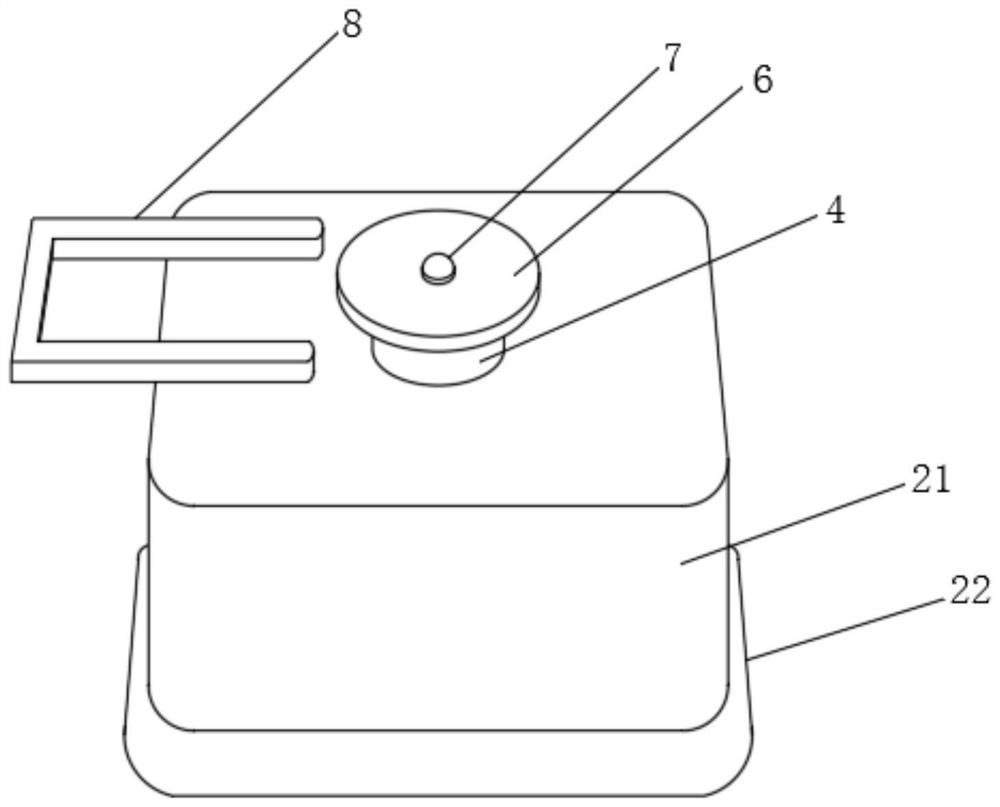

[0031] like Figure 1-3 As shown, a power generation system utilizing waste heat of a marine diesel engine, the system includes:

[0032] A floating cover 2 floating on the sea surface and connected to the exhaust gas outlet of the marine diesel engine through the exhaust gas pipeline 1; wherein, the diesel engine exhaust gas is the gas purified by the diesel engine exhaust gas purifier 10, and the diesel engine exhaust gas purifier 10 is arranged inside the ship and connected to On the exhaust gas pipeline 1, the gas meets the atmospheric discharge standard; the floating cover 2 includes an outer cover body 21 with an open bottom and a floating body 22 fixed on the bottom end surface of the outer cover body 21, and the floating body 22 adopts foam or air bags; The exhaust gas pipeline 1 includes an exhaust gas outlet pipe 11 and a corrugated pipe 12. One end of the bellows pipe 12 extends to the interior of the ship to connect with the exhaust gas outlet of the diesel engine,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com