Prefabricated floor slab, detachable steel-concrete composite floor system and construction method thereof

A technology of prefabricated slabs and concrete, applied in the processing of floors, building materials, structural elements, etc., can solve problems such as difficult disassembly, inability to dismantle, excessive deformation of bolts, etc., to achieve guaranteed performance, convenient dismantling, and stability and reliability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

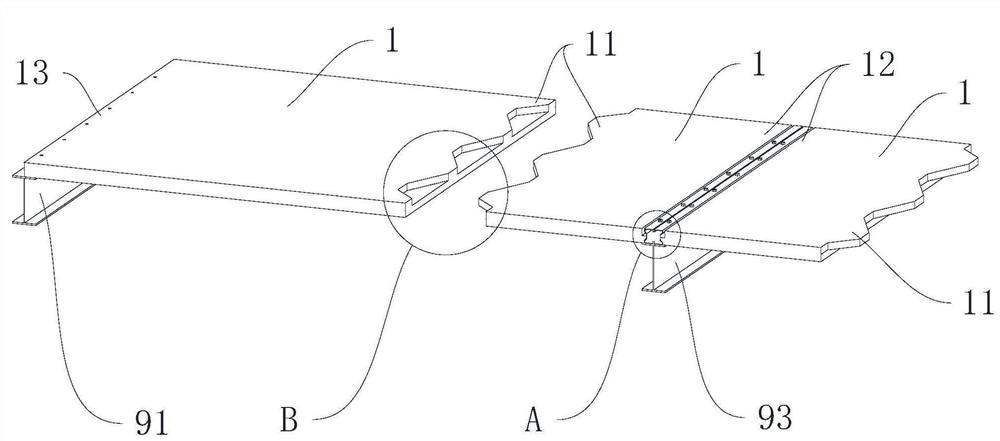

[0078] Refer below Figure 1-Figure 10 A detachable steel-concrete composite floor according to a specific embodiment of the present invention is described.

[0079] The prefabricated floor slab of this embodiment includes frame beams 91 and a plurality of prefabricated floor slabs described above.

[0080] The frame beam 91 defines a plurality of installation units 92, and the frame beam 91 is provided with a plurality of secondary beams 93 arranged at intervals, and each secondary beam 93 corresponds to a plurality of installation units 92 distributed along the vertical direction.

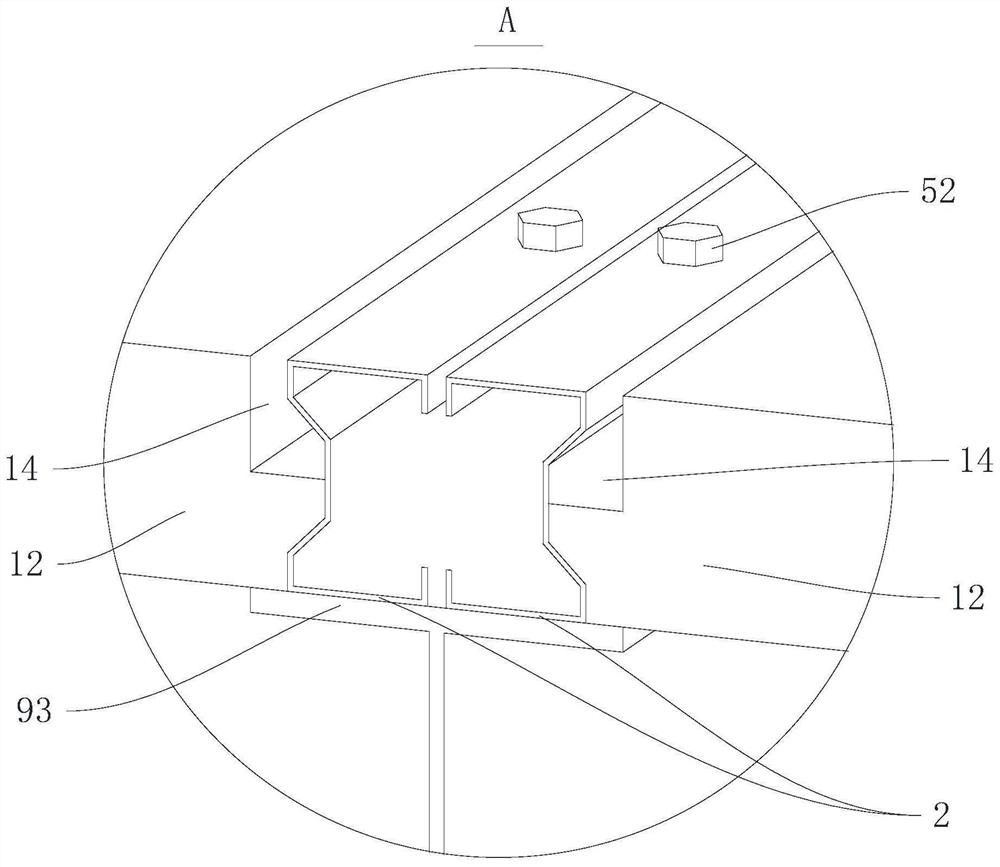

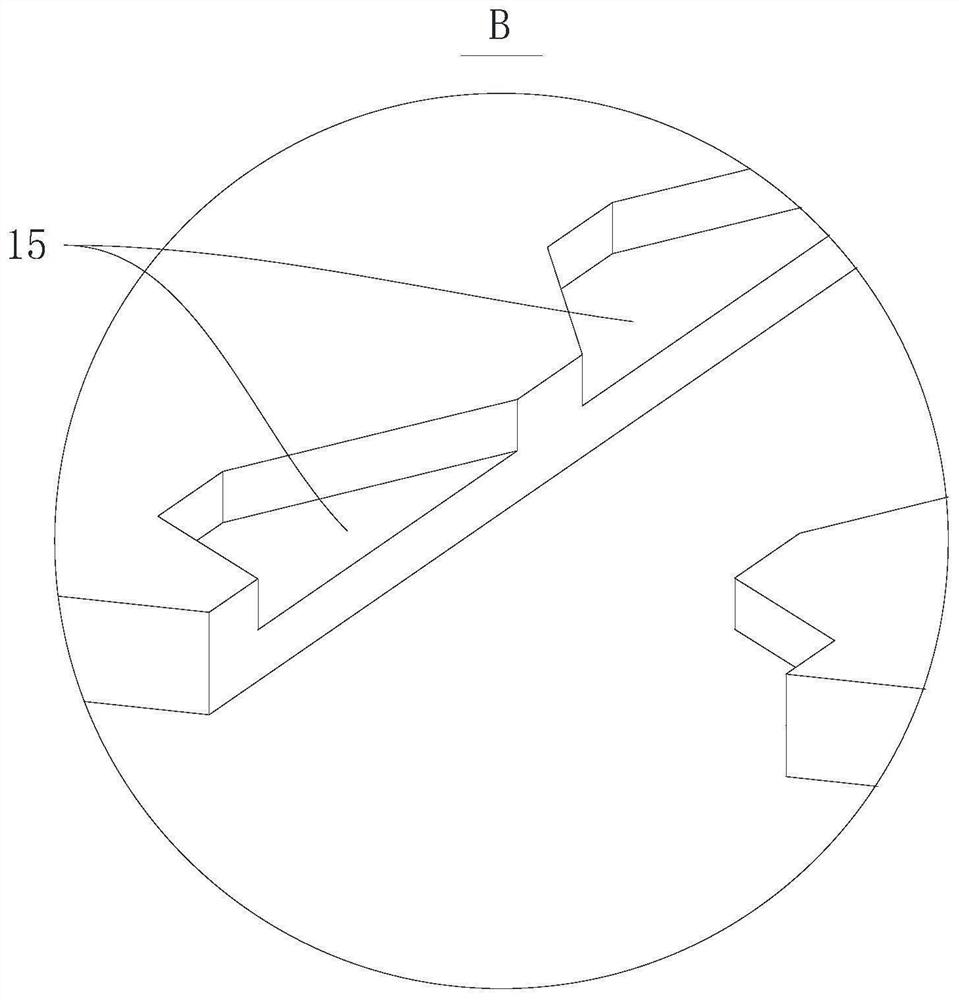

[0081] The shear sides 12 of two adjacent prefabricated slabs 1 of the prefabricated floor are arranged on the secondary beam 93 , the embedded components of the prefabricated floor are detachably arranged on the secondary beam 93 , and the prefabricated floor is also detachably connected with the frame beam 91 .

[0082] The prefabricated floor slab includes a plurality of prefabricated panels ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com