Nut demounting machine

A nut machine and nut technology, applied in ceramic molding machines, unloading devices, metal processing, etc., can solve the problems of increased labor costs, reduced work efficiency, inconvenient use, etc., and achieves strong practicability, low cost, and high precision Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

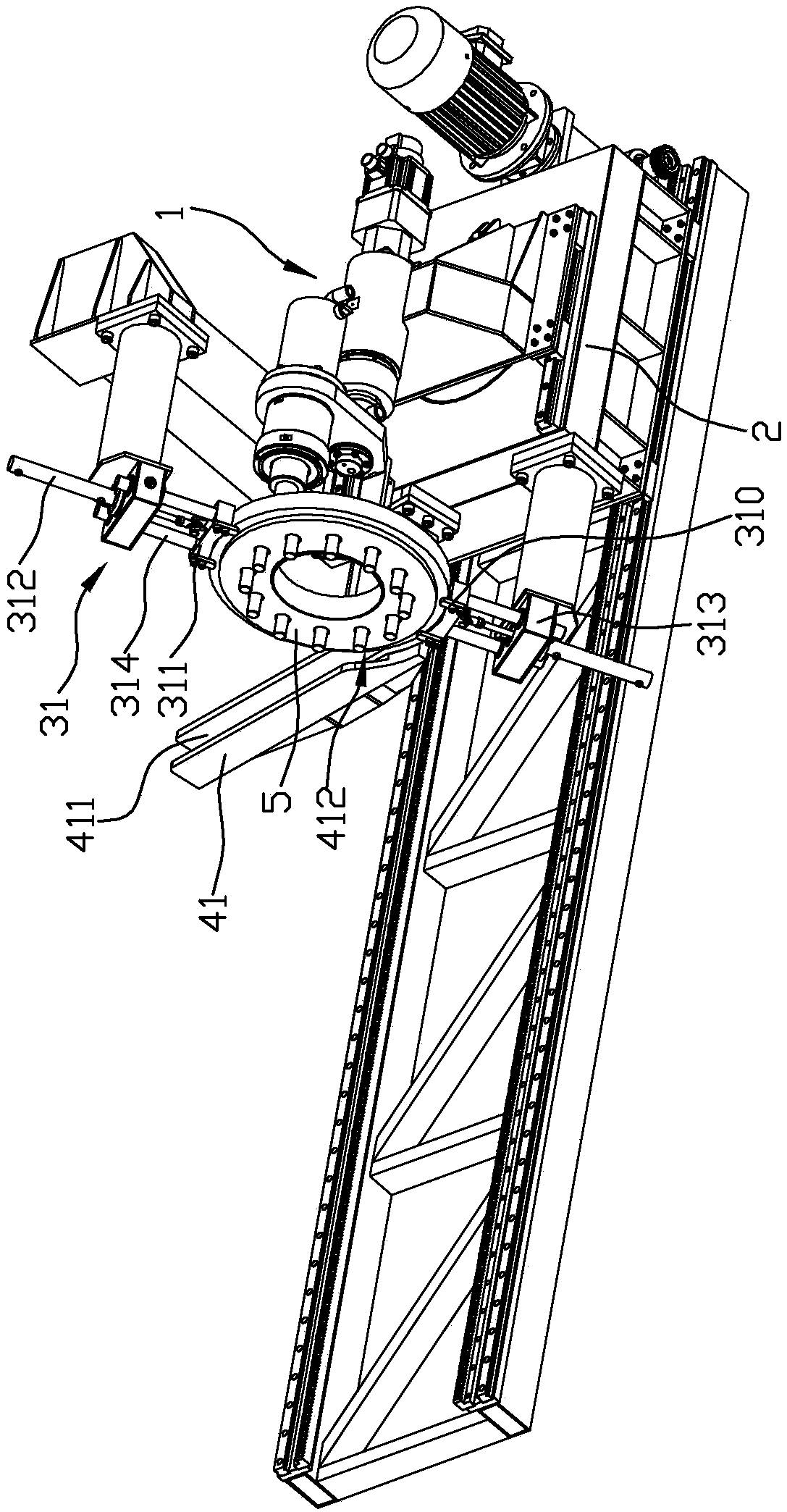

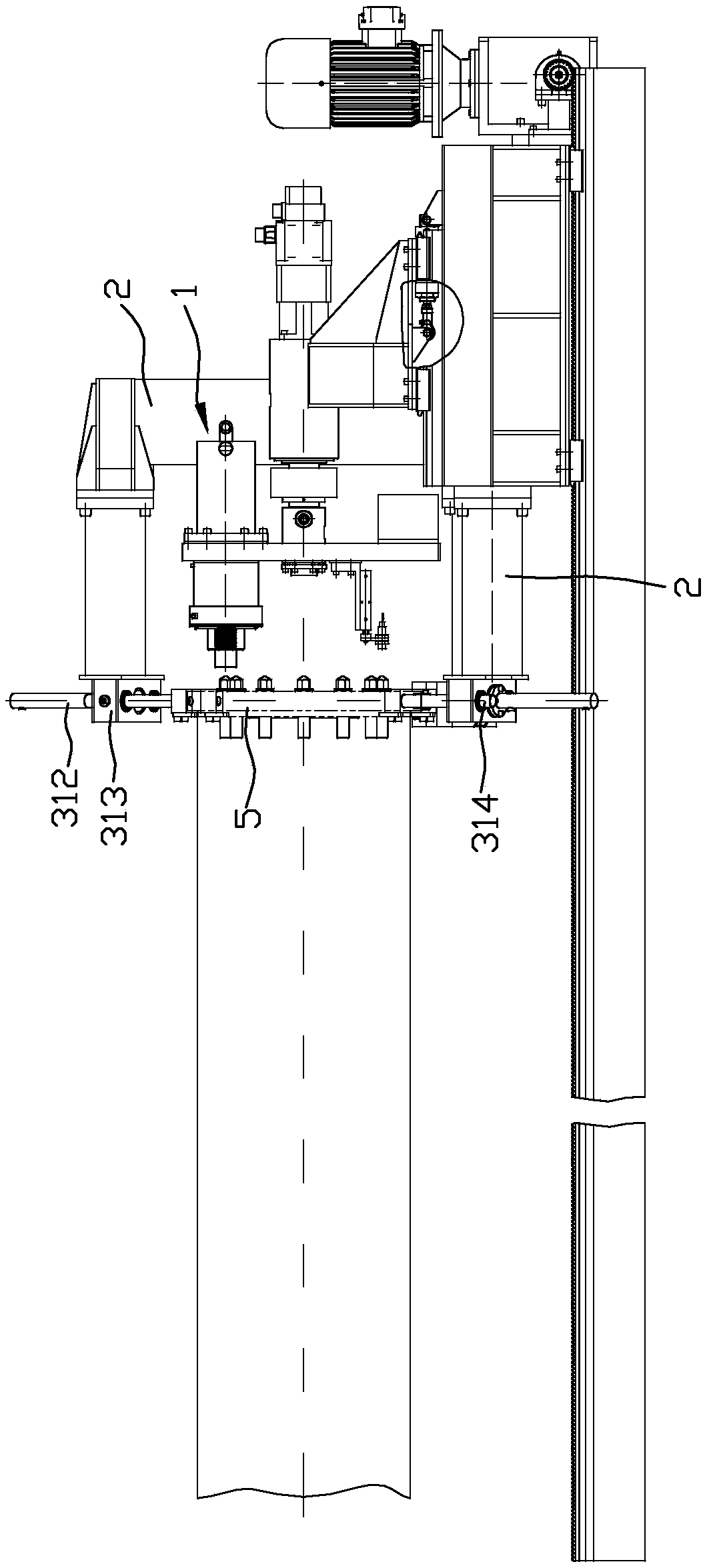

[0030] Such as Figures 1 to 6 As shown, it is the first embodiment of the present invention, the nut removal machine of this embodiment includes an organic platform 2, a fixing structure for clamping the end plate 5 of the pipe mold and being arranged on the machine platform 2 and facing the end The nut on the plate 5 is disassembled and the nut assembly 1, the conveying device that can remove the end plate 5, wherein,

[0031] The fixed structure is arranged on the machine platform 2, and the fixed structure is a clamping mechanism 31 which is arranged oppositely and clamps the end plate 5 of the pipe mold. The clamping mechanism 31 includes a clamping part 311 adapted to the outer peripheral edge of the end plate 5 and a first driving mechanism 312 that drives the clamping part 311 to move. The first driving mechanism 312 is an oil cylinder, an air cylinder or other driving mechanisms , in this embodiment, the first driving mechanism 312 is an air cylinder. In order to al...

Embodiment 2

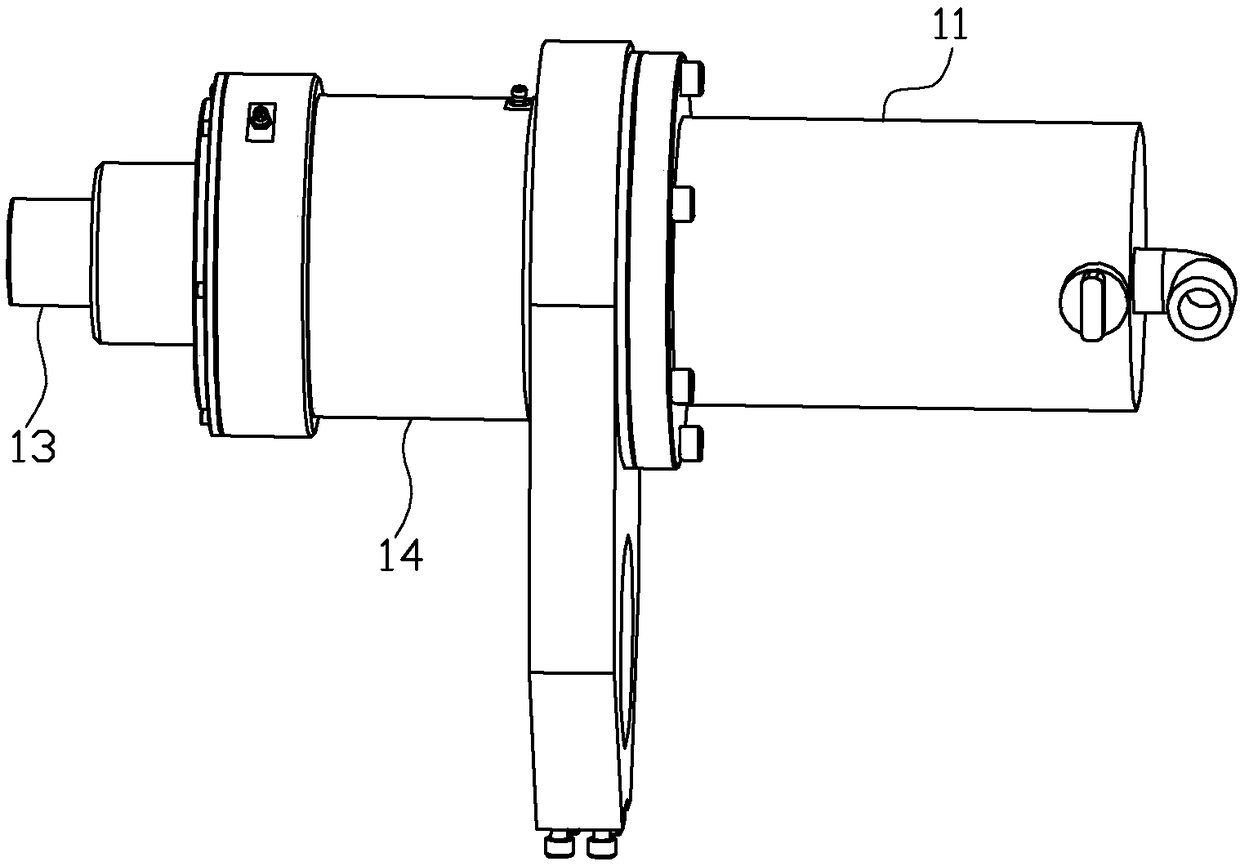

[0042] Such as Figure 7 to Figure 11 As shown, it is the second embodiment of the present invention. The difference between this embodiment and the above-mentioned embodiment one is: a. The circumferential limit structure between the demoulding shaft 12 and the output shaft 111 of the motor 11 is different: the motor 11 The output shaft 111 of the output shaft 111 is inserted in the socket 122 of the demoulding shaft 12, and the outer peripheral wall of the output shaft 111 and the inner peripheral wall of the socket 122 are correspondingly provided with a keyway 110, and the two keyways 110 are connected by a key (such as a flat key) so that the output shaft 111 and the demoulding shaft 12 are circumferentially limited.

[0043] b. The axial limit structure between the demoulding shaft 12 and the output shaft 111 of the motor 11 is different: a step portion 123 is formed on the inner wall of the demoulding shaft 12, and a stop piece 124 is provided on the front end of the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com