Preparation method of chitosan oligosaccharide, chitosan oligosaccharide and chitosan oligosaccharide health-care product

A technology of chitosan oligosaccharides and health care products, which is applied in the field of preparation of health care products, can solve problems such as side reactions at the electrode, operational hazards, etc., and achieve the effect of reducing dosage and increasing application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

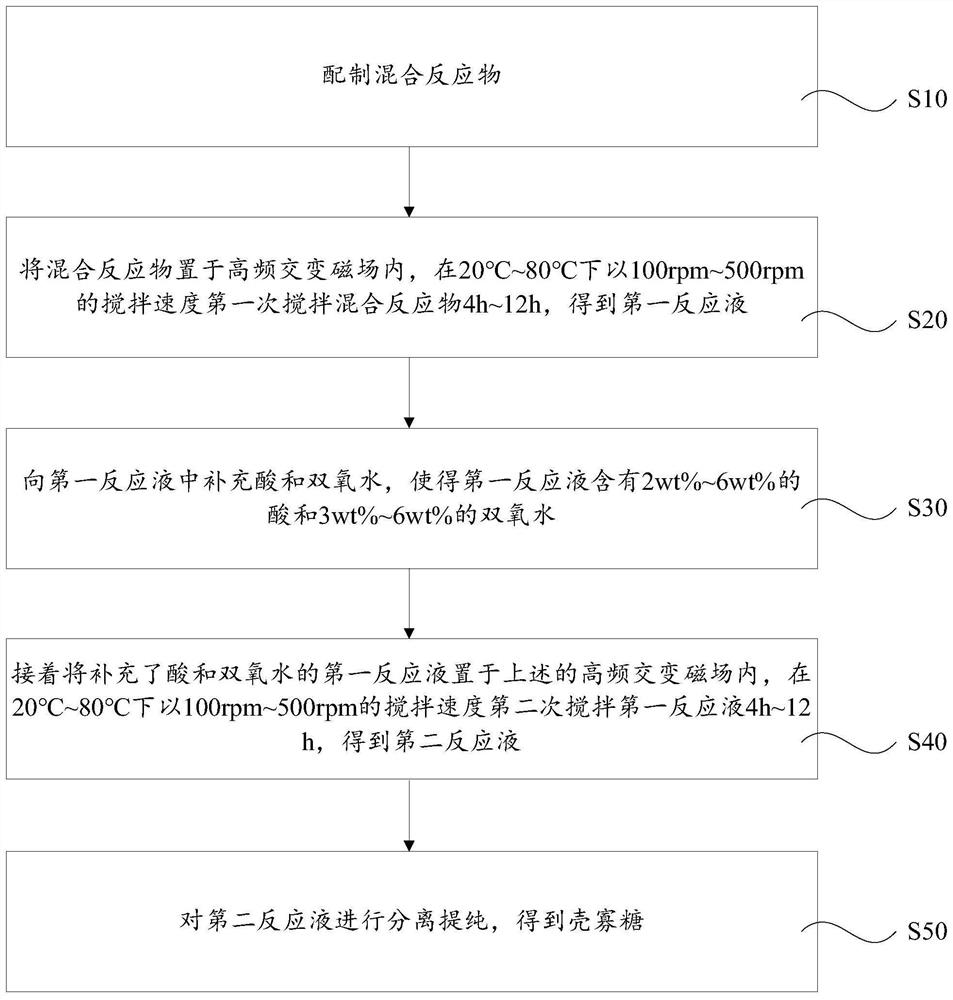

[0026] like figure 1 The preparation method of the chitosan oligosaccharide of one embodiment, comprises the steps:

[0027] S10, preparing a mixed reactant.

[0028] Specifically, the mixed reactant contains 10wt%-30wt% chitosan, 2wt%-6wt% acid and 3wt%-6wt% hydrogen peroxide.

[0029] Generally speaking, chitosan can choose chitosan with a molecular weight of 300KDa-580KDa and a deacetylation degree of 70%-90%.

[0030] Preferably, the mixed reactant contains 15wt%-25wt% chitosan.

[0031] Generally, the acid can be hydrochloric acid or acetic acid.

[0032] In other embodiments, other types of acids may also be selected.

[0033] Preferably, the operation of preparing the mixed reactant is: mixing the chitosan and acid solution, and then adding the hydrogen peroxide solution to obtain the mixed reactant.

[0034] S20. Place the mixed reactants in a high-frequency alternating magnetic field, and stir the mixed reactants for the first time at a stirring speed of 100 rpm ...

Embodiment 1

[0060] Mix chitosan with a molecular weight of 500KDa and a deacetylation degree of 85% and a 10wt% hydrochloric acid solution, and then add a 10wt% hydrogen peroxide solution to obtain a mixed reactant. The mixed reactant contained 20wt% chitosan, 5wt% acid and 5wt% hydrogen peroxide.

[0061] Place the mixed reactants in a high-frequency alternating magnetic field controlled by a high-frequency magnetic field generator, stir the mixed reactants for the first time at 60°C at a stirring speed of 300rpm for 6h, and control the plane formed by the first stirring and the high-frequency alternating Change the magnetic field to be vertical to obtain the first reaction solution. Wherein, the magnetic field strength of the high-frequency alternating magnetic field is 300 mT, and the frequency of the high-frequency alternating magnetic field is 250 KHz.

[0062] Add acid and hydrogen peroxide to the first reaction liquid, so that the first reaction liquid contains 5wt% acid and 5wt% ...

Embodiment 2

[0066] Mix chitosan with a molecular weight of 500KDa and a deacetylation degree of 85% and a 10wt% hydrochloric acid solution, and then add a 10wt% hydrogen peroxide solution to obtain a mixed reactant. The mixed reactant contained 20wt% chitosan, 5wt% acid and 5wt% hydrogen peroxide.

[0067] Place the mixed reactants in a high-frequency alternating magnetic field controlled by a high-frequency magnetic field generator, stir the mixed reactants for the first time at 60°C at a stirring speed of 300rpm for 6h, and control the plane formed by the first stirring and the high-frequency alternating Change the magnetic field to be vertical to obtain the first reaction solution. Wherein, the magnetic field strength of the high-frequency alternating magnetic field is 200 mT, and the frequency of the high-frequency alternating magnetic field is 120 KHz.

[0068] Add acid and hydrogen peroxide to the first reaction liquid, so that the first reaction liquid contains 5wt% acid and 5wt% ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| frequency | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com