SCM-33 molecular sieve as well as preparation method and application thereof

A technology of SCM-33 and molecular sieves, applied in the field of molecular sieves, can solve the problems of inability to introduce catalytic active centers, high synthesis costs of molecular sieves, and low crystal growth rate, and achieve the effects of shortening the synthesis cycle, strong acidity, and short crystallization time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

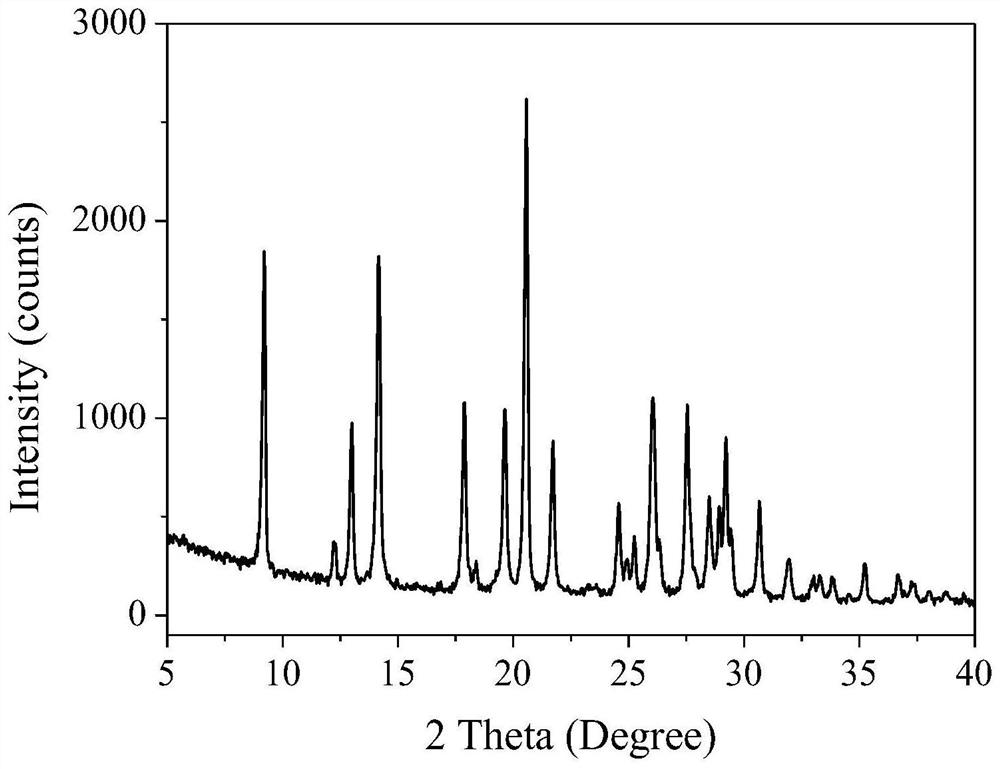

[0049] 2.5g of sodium metaaluminate (Al 2 o 3 41wt%,Na 2 (58wt%), 17.5g potassium hydroxide solution (30wt%) are dissolved in 28g water, add 39.4g isopropyltrimethylammonium hydroxide solution (20wt%) and stir well, finally slowly add 60g Ludox AS- 40 silica sol, stirred for 1 hour, then put the above mixture into a crystallization kettle lined with polytetrafluoroethylene, and placed it in an oven at 155°C for crystallization for 144 hours. After the reaction, the solid was filtered, washed with distilled water and dried at 100°C to obtain the original powder SCM-33 molecular sieve. XRD patterns such as figure 1 shown. The original powder solid is placed in a muffle furnace and roasted at a temperature of 550 ° C for 5 hours to obtain the final product. The XRD pattern is as follows: figure 2 shown. The SEM photo of SCM-33 molecular sieve is as image 3 shown.

[0050] Wherein, the XRD spectrogram data of the final product gained in embodiment 1 is as shown in table...

Embodiment 2

[0055] 2.5g of sodium metaaluminate (Al 2 o 3 41wt%,Na 2 (58wt%), 13.7g potassium hydroxide solution (30wt%) are dissolved in 64g water, add 39.4g isopropyltrimethylammonium hydroxide solution (20wt%) and stir well, finally slowly add 60g Ludox AS- 40 silica sol, after stirring for 1 hour, put the above mixture into a crystallization kettle lined with polytetrafluoroethylene, and place it in an oven at 160°C for crystallization for 120 hours. After the reaction, the solid obtained SCM-33 zeolite molecular sieve after filtration, washing, drying, and roasting (aftertreatment reaction conditions are the same as in Example 1), and the XRD spectrum and figure 2 similar. Wherein, the XRD spectrogram data of embodiment 2 gained final products are as shown in table 2:

[0056] Table 2

[0057]

[0058]

Embodiment 3

[0060] With 7.5g sodium hydroxide solution (30wt%), 15g potassium hydroxide solution (30wt%), 40g H 2 O, 47.3g isopropyltrimethylammonium hydroxide solution (20wt%) stirs evenly, slowly adds 45g Ludox AS-40 silica sol under stirring, adds 6.6g USY molecular sieve (SiO 2 / Al 2 o 3 =12), after stirring for 1.5 h, the above mixture was put into a crystallization kettle with a polytetrafluoroethylene liner, and placed in an oven at 165° C. for crystallization for 96 hours. After the reaction, the solid obtained SCM-33 zeolite molecular sieve after filtration, washing, drying, and roasting (aftertreatment reaction conditions are the same as in Example 1), and the XRD spectrum and figure 2 similar. Wherein, the XRD spectrogram data of embodiment 3 gained final products are as shown in table 3:

[0061] table 3

[0062]

[0063]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com